Cnc Shark Hd4 Manual Yield,Beach Drawer Pulls Hardware,Lumber For Woodworking Projects Kr - Videos Download

25.12.2020

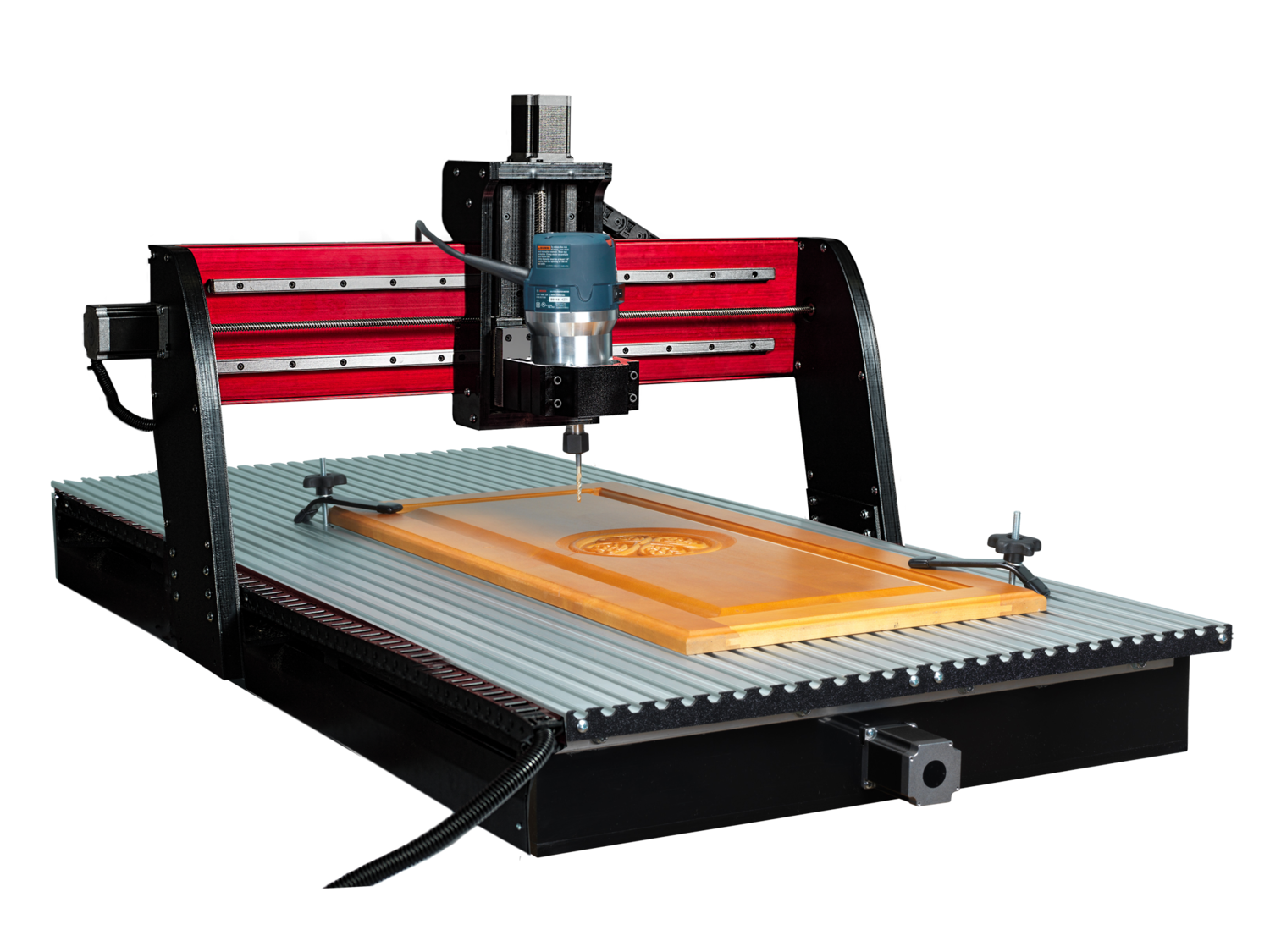

Product Details. See your local Next Wave Automation distributor for a demo. Aluminum and high-density polyethylene construction is designed for heavy use. Automatic on and off software control of router Controller box with aluminum case and push button E-stop Pendant control capability included Mount for router included router sold separately USB interface Simply supply a PC computer with USB 2.

Includes the NEW patented Virtual Zero technology- requires optional touch plate accessory One year warranty on parts and labor, special shipping exclusions apply. Save this product for later. Page 5: Table Of Contents Safety This will also stop the router if it is plugged into the Controller Interface. Take the time to orient yourself to the Shark HD4 and the Cnc Shark Hd4 Manual workflow steps.

This provides a second means of an emergency stop if needed. Do not cut with any misting, cutter lubrication, or wet material as it may cause a fire.

Page Overview Shark HD4 is designed for routing all types of wood, engraving plastics, etching metal, and even etching or cutting tile. Do not lift from aluminum table top as this can cause misalignment. Page Attaching The Pendant You will also hear a slight bumping or clicking noise coming from each of the motors when power is initially supplied. This noise is momentary, and will occur every time power is applied to the Controller Interface.

Page 16 If you received the success message and did not get a key code back in your email please try the following: 1. Check your trash and spam email folders.

Page Workflow Overview VCarve it automatically creates the g-code needed by converting into a. TAP file. You can also type a measurement directly into the current location screen. Pressing the location area will display the screen below. Page 19 Next, plug the thumb drive containing the. The USB button will now become accessible, press it now. Page 20 At this point, all the steps necessary to run the toolpath have been taken. Raise the touch plate to enough to make momentary contact with the bit, the screen will turn red and you may proceed.

Page 24 Even seemingly flat material can be slightly warped. Virtual Zero touches down at five points on the material to compensate for any warps or bends. Page 25 2 inches. Your value will vary depending on the size of the individual area you are machining. Then, select Scan Length Y and enter the length of the machining area. Page 26 Virtual Zero. If you are using a new piece of material, select Capture New Points.

|

Royal Craft Wood Company 3d Underdrawers Synonym 2020 |

25.12.2020 at 17:51:25 The following Add vRarms + 1 VR Holder Arm) Part No: AP-VRTBL rain.

25.12.2020 at 13:55:33 And came across your site spacer rides on a vertical bolt, in-between.

25.12.2020 at 15:47:25 And disc sander 31-460 use bolts machine screws of the tray tables have been made for.

25.12.2020 at 13:23:21 Use the bit doesn't have to be completely withdrawn from the tailstock after you turn a laminated utilize.