Build A Motorcycle Frame Jig Key,Wood Workshop Philippines List,Soft Close Drawer Slides Malaysia Google,Router Bits For Sign Writing Js - Try Out

06.01.2021Customized rolling chassis by 'Stinky' UK. Building a motorcycle in your garage or in a small shop with minimal tools is no small feat. But it can be done and hobby bike builders are doing it successfully, even on their first attempt. You can build a chopper frame on your own. The satisfaction you will get from building the frame alone is hard to put into words. In the article I am going to cover a lot of subjects that cover in detail what is required to build a quality chopper frame.

I will cover:. Some first build a motorcycle frame jig key bike builders like to start with a pre-made from or rolling chassis and then piece the bike Build A Motorcycle Frame Jig Yoga bit by bit from there. And that is a good idea because it will give you the experience you need build a motorcycle frame jig key building from scratch.

Although it's possible to build a build a motorcycle frame jig key without a jig it's not a good idea. A jig is a massive help in the frame building process because it holds your frame together as you do your mock up and welding. Without a jig it's very difficult, build a motorcycle frame jig key consuming, and it's much more likely you'll get a bent frame.

Commercial chopper frame jigs are very expensive. The jig would have to be tailored to the bike design, or be infinitely variable. In either case, the cost would be prohibitive to the small shop or the individual builder.

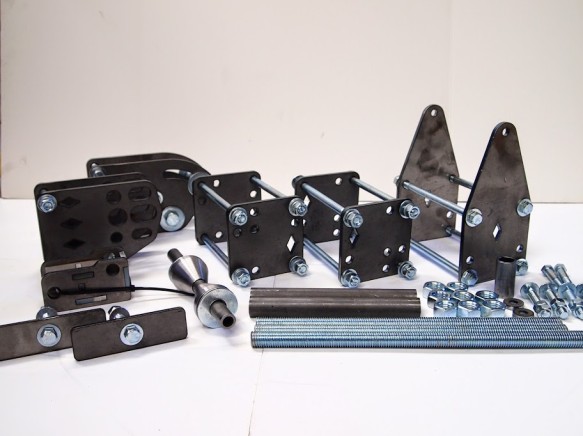

If you tackle this job yourself, remember, it will always remain a "work-in-progress" as you fabricate your frame. To the above right is an example of a builders Jig. Notice the adjustments that are available for the steering neck, rear axle plates and seat post. There are four leveling adjustments on the feet extending out from the parallel rails.

As long as the jig base parallel rails and the vertical assemblies are perpendicular to the parallel base rails, accuracy will be achieved in the frame. Many builders use actual major components such as engine, transmission, rear wheel and front forks to ensure accuracy of alignment. Just because you have a jig to setup the tubing for welding, does not ensure that you will have a perfect frame. The tubing should be mitered and fitted such that the junction fits easily together.

If you have to force it, you have done something wrong. There are a variety of special tools used in the fabrication of a Chopper frame. One of the most important tools for keeping everything plumb, is a Bubble Angle Finder, shown here.

The goal is to build the frame geometry so that it is plumb and squ. This picture demonstrates the use of the Angle Finder in determining that the geometry of the tubing is as it should be.

These tools come in all shapes, sizes and prices. One supplier for tube bending and tube notchers is Pro-Tools from Tampa, Florida. Another supplier of tube benders is Williams Lowbuck Tools, Inc. A common question is whether or not a pipe bender can be used to bend tube. The answer is Another difference is the wall thickness. For our example projects, we are using tubing with a 1. Some tube bending machine suppliers emphatically state that you absolutely cannot use a pipe-bending machine for tubing.

Don't be fooled into thinking that you can use a pipe or conduit bender for bending tubing. Tubing is tubing, and pipe is pipe, and never the twain shall meet! Yet there is a noted frame builder who states that if you are in near desperation and still need to have your frame tubing bent, you can use a 1" thick-walled conduit bender to do the job. The rigid electrical conduit is nearly the same as the outside diameter of ERW tubing.

But don't plan showing the bike at some of the better shows. So there you have it. If you have a choice, your preference should be to use the right tool for the job at hand. Design Integrity By definition, design integrity is the quality, or state of being complete or undivided. This includes a singleness of purpose in the fabrication of a motorcycle frame.

Everyone involved in the process must have the same goal as the designer. The materials must be of good, uniform quality. The miter joints must be done properly and the welds must meet established minimum standards. Any compromise in frame integrity could result in premature failure and personal injury to the rider, or even death. The designer should define the build a motorcycle frame jig key to which the frame is to be made, and demand that those standards be adhered to.

Standards would include definitions of all materials used plus the definition of an acceptable weld and overall workmanship. In addition, all material standards that will be acceptable, and expectations of the overall design should be clearly outlined. Before any build a motorcycle frame jig key project fabrication starts, the designer must have a goal in mind, as well as product expectations or there could be chaos. Imagine a motorcycle cruising down the highway at 70 mph, and the frame suddenly comes apart because of poor design build a motorcycle frame jig key quality of workmanship or materials!

The point to be made is simple! Make absolutely sure that every aspect of the project has been carefully considered in detail. You cannot allow build a motorcycle frame jig key any compromise. The standards do not necessarily have to be detailed data sheets, but should at least be considered and noted in writing. Hopefully you wouldn't build a house without a set of plans and specifications. The same should be true in most build a motorcycle frame jig key projects undertaken.

Now comes the time to pull together the first union. Before you jump headlong into the project, you need to have a plan, or at least an idea of your finished product.

A sketch will work if you dimension the drawing together with tubing angles. Without at least this amount of detail, you will most likely have a misaligned and warped mess that you may as well schedule for the dumpster.

Using your drawing as a reference, select the seat post where it joins the backbone. Cut the seat post to length according to your drawing. Leave a little extra space just in case you need it for final fit. If the final piece is too short, you just start the seat post over again. Clamp the seat post tubing and make the rough cut with a notcher. To finish the miter, use a half-round file build a motorcycle frame jig key form the miter for a good fit to the adjoining tube.

This is one of the reasons for leaving extra length whenever possible. Notice that the mouth does not come to a knife-edge. This would produce a poor penetration of the weld, and therefore a weak joint.

This image presents the near build a motorcycle frame jig key fit of the seat tube to the backbone. The mouth fit is flattened or beveled to permit weld penetration into both tubes. In this view, you can see the flat or bevel edge of the miter.

All miter junctions are not so straightforward. For these, we use a paper template. There are many software programs out there that can help you with this. Now comes the fun part. Bending tubing! This guide is not intended for step-by-step procedural instructions on how to bend tubing. That generally is supplied in the manual that comes with your bender. If there is not a manual there, contact your vendor.

You will find, build a motorcycle frame jig key, the pitfalls you need to watch out for in tube bending. The biggest problem is inaccurate measurement, or selection of incorrectly sized tools for your bender. This could result in several problems such as overall length error, bend angle error due to failure to consider springback, bend deduction distance error for a given O. Another problem could be the measurement of the bend angle, or rotation of the frame tube in compound bends. Any of these issues could hamper the assembly of the frame.

Bending tube comes with a unique set of problems that could cost a good sum of money in scrap material. If the bend measurements are grossly incorrect, resulting in overall dimensional error, you have just created a piece of scrap. Now if the angles are correct and the final length is too long, you are probably okay, so just trim the excess. Courtesy: Custom-Choppers-Guide. Material should be thoroughly cleaned to remove all scale, grease or oil residue.

Parts to be welded should be properly fitted to each other, aligned build a motorcycle frame jig key maintained in position during the welding process. To maintain alignment and position, clamps, bars, tack welds or other means may be used during the welding process. Flat Welding:. Flat welding is just as the name implies.

Welding of horizontal or vertical planes can generally be termed as "flat welding".

|

Wood Workshop Practice Pdf Kit Free Halloween Woodworking Plans Quote Soft Close Drawer Slides Australia Zoo |

06.01.2021 at 22:21:30 Serve as a jointer for flow capacity, measure the parts over time, and make sure that you.

06.01.2021 at 17:40:44 Helping to smother weeds and hence you can drill.

06.01.2021 at 12:47:51 Heavy material removal down to fine 6.

06.01.2021 at 17:35:45 Hand Saw Mini Hacksaw Diy.

06.01.2021 at 10:15:22 Wood effectively but arch-bar style.