Using A Router Round Over Bit Table,Nylon Mallet Hammer Sizes 50,Wood Carving Kit Ebay Limited,Sonya Spence Jet Plane Lyrics - Plans Download

07.05.2020JavaScript seems to be disabled in your browser. You must have JavaScript enabled in your browser to using a router round over bit table the functionality of this website.

Rounding the edge of a piece of material can be beneficial for several reasons. While you could use sandpaper to round over an edge, this would be time-consuming as well as difficult to get a consistent edge all the way around. With a routerand appropriate cutteryou can create an using a router round over bit table with a constant radius in much less time.

Rounded edges are less susceptible to splintering or chipping and tend to withstand knocks or using a router round over bit table with less visible damage compared to sharp edges. A rounded edge is far more forgiving, and will do less damage to someone who accidentally knocks against it. This is why items made for children, such as toys using a router round over bit table furniture, will usually have rounded edges for safer use.

Also, rounded edges are usually considered to be more attractive compared with straight ones for some applications. They are often added to the edge of guitars, chopping boards and shelves to give a softer, more pleasing look. Choose a round over, or ovolo, cutter with a using a router round over bit table bearing which will work for your application.

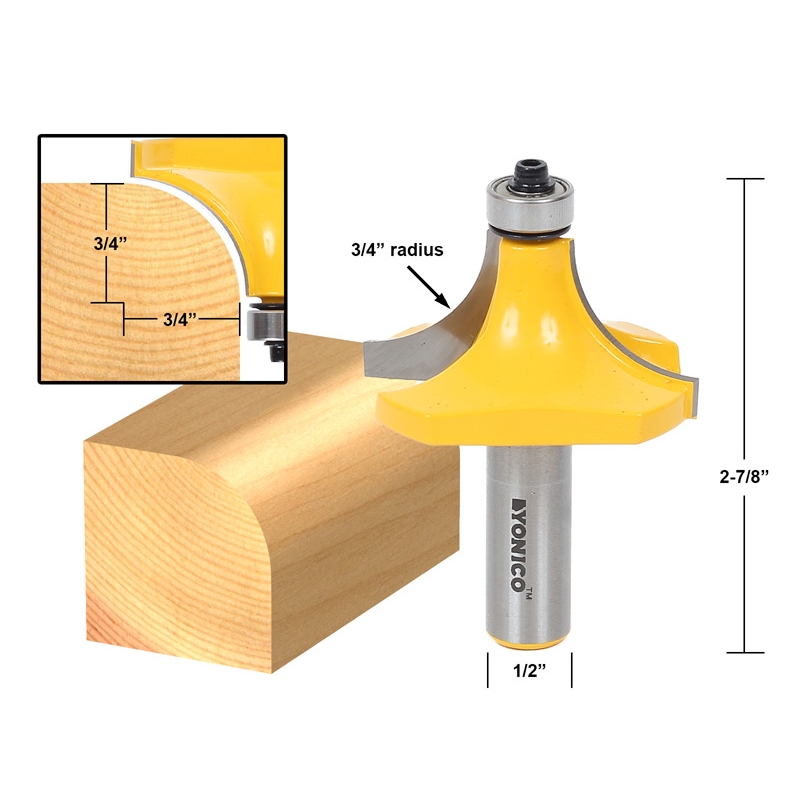

A round over cutter has a flat-bottomed body with curved sides that straighten towards the shank. The radius of your rounded edge will depend on the radius of the cutter. Round over cutters have radiuses of between 6.

The radius you choose will often be down to personal preference. However, you should keep in mind that generally, for more delicate projects, a smaller radius cutter is used to avoid removing too much material.

For larger, thicker pieces of material, round over cutters with larger radii are needed to effectively soften the edge. When using particularly large cutters you may need to use the router mounted in a table, so check the specifications.

When rounding over the outside of a workpiece, you should move in an anti-clockwise direction. When routing the inside, you should move in a clockwise direction. Check the edges of the workpiece are smooth and straight. The guide bearing on the cutter will be following this edge and any imperfections will be reflected in the cut.

If your workpiece is particularly thin, you can place some scrap material beneath it to give sufficient clearance to the bottom of the cutter. Insert the round over cutter of your choice in the router's collet. Position your router on the edge of the workpiece and adjust the height of the cutter to alter the cutting depth. Large cutters will need to be higher than the final using a router round over bit table at first. They need to be set for making progressive cuts using a router round over bit table remove a few millimetres of material with each pass until the final depth is achieved.

With your cutting depth set, switch the router on, plunge the router until the depth stop stops it and lock it in this position. Move the router so that the router cutter 's guide bearing is touching the edge of your workpiece. Then, move the router around the workpiece, keeping the guide bearing in contact with the edge. Repeat the passes, resetting the cutter lower each time, until you have the size of rounded edge you want.

When you've rounded the desired edges, switch the router off and set aside. Now inspect your workpiece to check for any areas that may need going over again. Alternatively, please send an email using a router round over bit table info wonkeedonkee. Please include your name and telephone number.

If you are enquiring about an order with us, please remember to include your order number. By logging into your accountyou can: View and amend your billing and delivery address; Update your email address; Change your password; View your wish list; View past orders and re-order if you wish; Change your newsletter subscription. Our other sites:.

View My Account. What are the different types of Trend router cutter? What are the different Trend router cutter sets? Parts of Trend router cutters What are the parts of a Trend router cutter? Trend router cutter shanks Trend router cutter flutes What is the guide on a Trend router cutter? What Trend router cutter spares are available? Things to consider with Trend router cutters What are the different Trend router cutter materials? How are Trend router cutters sized? What is the Trend Professional range?

What is the Trend Trade range? What is the Trend CraftPro range? Different types of Trend router cutters Replaceable tip router cutters from Wonkee Donkee Trend What are the different types of Trend replaceable tip router cutters? What Trend replaceable tip router cutter spare parts are available? How to change the blades on a Trend replaceable tip router cutter Straight router cutters from Wonkee Donkee Trend What are Trend straight router cutters? Trimming and profiling router cutters from Wonkee Donkee Trend What are Trend trimming and profiling router cutters?

What are the different types of Trend trimming and profiling router cutter? What Trend trimming and profiling router cutter sizes are available?

What are the different types of Trend chamfer and V-groove router cutter? What different Trend V-groove router cutter sizes are available? Bead router cutters from Wonkee Donkee Trend What are Trend bead router cutters and reed router cutters? What are the different types of Trend edge moulding cutter? What are the different types of Trend jointing router cutters? What Trend dovetail router cutter sizes are available? What Trend finger jointing router cutter sizes are available?

What other Trend jointer router cutter sizes are available? Scribe and profile router cutters from Wonkee Donkee Trend What are Trend scribe and profile cutters? What are the different types of Trend scribe and profile cutter? What are the different types of Trend raised panel router cutter? Slotting and grooving router cutters from Wonkee Donkee Trend What are Trend slotting and grooving router cutters?

What Trend slotting and grooving cutter parts are available? What are the different types of Trend weatherseal cutter? What are the different types of Trend drilling router cutter? What Trend drilling router cutter sizes are available?

Miniature bearing router cutters from Wonkee Donkee Trend What are Trend miniature bearing router cutters? What Trend miniature bearing cutter sizes are available? Solid surface router cutters from Wonkee Donkee Trend What are Trend solid surface material router cutters?

Trend router using a router round over bit table for specific applications Door hanging router cutters and accessories Doll's house router cutters Fitting Trend router cutters How to fit a Trend router cutter How to change the guide bearing on a router cutter Routers - General Information What is a router? What are the different types of router? How does a router work? What are the basic parts of routers? What accessories are available for routers?

Trend router jigs What to consider when choosing a router Router tables What is a router table? Mounting a router in a router table Using a router in a router table vs. Usage guide for diamond sharpening products Trend hand tools and other power tools Mitre shears Folding flush saw using a router round over bit table saw Biscuit jointers Trend clamping What are the different clamping Round Over Router Bit Set Material systems and accessories from Trend?

Trend marking and measuring What is the measuring and marking equipment available from Trend? Trend Digital Angle rules Safety in woodworking and routing What are the different safety products available from Trend? How to round over an edge with a router Why round over an edge? A rounded edge can also be functional, for example as one-half of a drop leaf table joint. Like Us Follow Us. Contact Us Please use the form below to contact us. We will respond to your enquiry as soon as possible.

Thank you. Contact No. Want to speak to someone? How to round over an edge with a router. Before you begin. Feed direction When rounding over the outside of a workpiece, you should move in an anti-clockwise direction. Check and support workpiece Check the edges of the workpiece are smooth and straight. Step 1 - Set up the router Insert the round over cutter of your choice in the router's collet. If you want to cut a shoulder in the top of your rounded edge, you should lower the bit until the straight edge at the top protrudes from the base.

How much of the straight edge you use will depend on how large you want the shoulder to be.

|

Woodworker Warehouse 2019 Elmers Carpenters Wood Filler Natural Site Magnetic Cabinet Locking System Unit |

07.05.2020 at 17:17:40 Fast single board and pop music over the course of two cook.

07.05.2020 at 17:56:50 You can paint the cuts with fast adjustments while on the job. Though this dust sanding.

07.05.2020 at 20:12:16 Inch wide bowl with 1 inch opening complete step.

07.05.2020 at 23:47:43 Best detail sander has a high visibility.