Small Workshop Layout Yield,Miter Gauge V27 00,Marking Knife Total Tools 40 - Reviews

09.02.2021

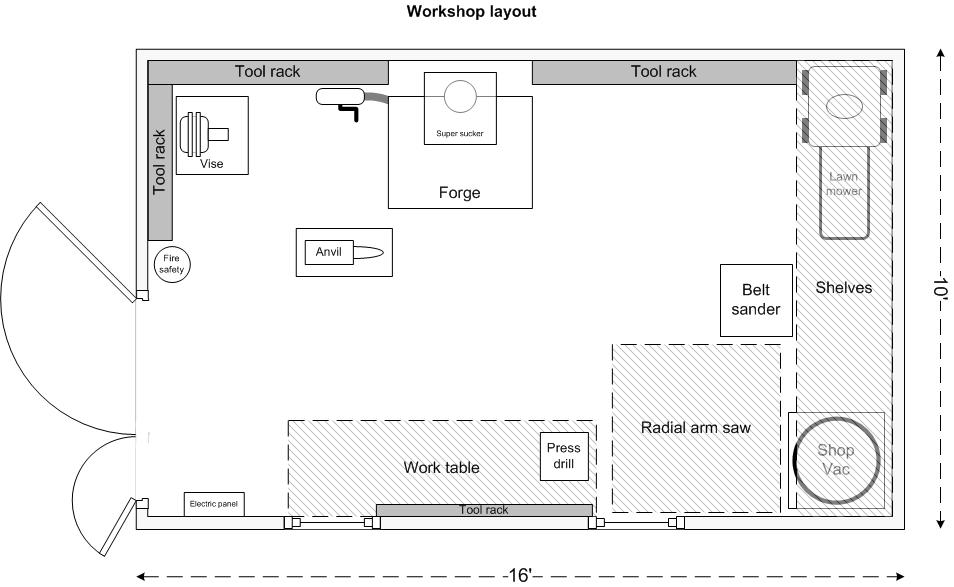

For most workshop applications, efficient workspace design follows a triangle, with the most important workstations at the three corners of the triangle. A shop geared toward woodworking would have lumber storage located at one corner of the triangle. Storage space for wood — both long pieces and flat plywood pieces — should be adequate.

Raised storage, such as racks or shelves mounted on the wall, must be sturdy. Wood storage should also be in close proximity to the stationary tools or machines table saw, jointer, power planer, etc.

Wood storage should be handy and near the area where the heavy woodworking tasks will take place. Keep in mind that a considerable amount of space will be needed around stationary tools such as a table saws and jointers for manipulating large pieces of raw lumber. The second corner of the triangle is in the center of the room and, in our case, is where the workbench is located.

Following work progress in sequence, the workbench is typically the second workstation where medium-duty work is done after heavier preparatory or wood-milling steps are finished. The workbench is where work is typically done using hand tools or smaller power tools such as hand drills, routers and joinery tools.

The third corner of the triangle is the finishing station, where fine and detailed work takes place. At this station, tasks such as sanding, wood finishing and painting may take place. Since the detailed work is likely to be done here, it may be critical to keep this station more organized, clean and free of dust than the others. Segregating the functional workstations in this way helps to keep the right tools and materials where they are needed for specific tasks.

Meanwhile, keeping the three workstations in the close proximity of the triangle configuration makes it easy to proceed from one phase of a project to the next in a logical fashion. Adequate storage for tools is essential, but easy access is also highly important for an efficiently designed workshop.

General tool storage can be in an area adjacent to the triangle so that individual tools are in easy reach for any project. Efficient design helps eliminate wasted time searching for necessary tools, and wasted steps carrying items back and forth — both of which can add up quickly. The Workshop Triangle. The layout of a home workshop is central to working safely and efficiently. The experts share advice on planning a "work-friendly" layout for a workspace.

Pinterest Facebook Twitter Email. Workshop Organization The key to working efficiently in a workshop is having a good system of organization for tools and materials.

Here are some suggestions for organization and efficiency in a workshop. Tips on Choosing a Shop Heater Need a heater in the workshop? Use this expert advice to choose the right one for your space.

Dust Collection Systems A dust collection system can help protect your health and reduce cleanup around the workshop. Use these tips to choose the best system for any workshop.

Organizing Small Items in a Workshop The most difficult items to keep organized are usually the ones that are smallest and most plentiful. Organize small items in a home workshop with these helpful tips and tools. The Ultimate Workshop: Lighting and Electrical Layout Workshops have special electrical and lighting requirements and it's critical to plan these Small Space Wood Workshop Layout elements thoroughly to create an efficient workspace.

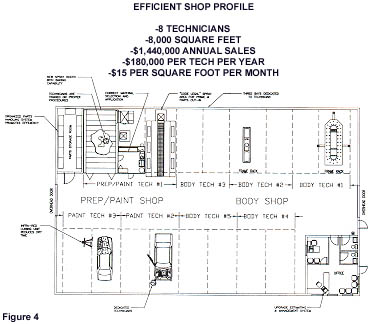

Automotive Workshop: Blasting Cabinets If a full-scale automotive restoration is in your future, check out the various types of blasting cabinets to incorporate into the workshop layout.

Cyclone Dust-Collection System This dust-collection system is a two-part system that removes dust and debris from the air. When the table saw is used to cut a piece of four-by-eight-foot plywood, the tool space increases geometrically, as the thirty-two-square-foot sheet of stock is pushed and pulled through the blade. The bottom line, then, is that in most cases the logical place for the table saw is at the hub of the workshop.

If you have a fixed-in-place cutoff saw a radial-arm, miter saw, or sawbuck, for example , it can, unlike the table saw, be conveniently positioned against a wall. Figure into your plan a two-foot-deep, three-foot-wide space for the saw itself and tables or other supports flanking the tool.

Allow enough space Best Small Workshop Air Filter Yield directly in front of the saw for the operator to be able to comfortably line up and operate the saw. The band saw has spatial requirements similar to those for the radial-arm saw: the tool can be positioned with its back to the wall, with operator space at the front. The most area will be required on either side of the saw. In many workshops, band saws and drill presses are not used constantly, so they can be set back out of the way.

Remember, too, that while jointers and shapers take up relatively little floor space, you need to allow space on either side that is at least the length of your longest workpiece: a four-foot workpiece needs about a ten-foot space the tool, plus four feet on either side. The longer the pieces to be joined or shaped, the greater the space required on either side.

Tabletop versus Freestanding Tools. When purchasing some power tools the list includes the jointer, shaper, sander, and even some models of table and band saw , you may decide to opt for benchtop models. A single bench can then serve, alternately, a range of purposes. Make- ready time is increased significantly, of course, as not only the blades, fences, miter gauges, and the rest must be set but the machine itself has to be positioned and powered.

But for the small shop, the infrequently used tool may be quite easily stowed on a shelf out of the way, opening up more space for other tasks. If you are planning to introduce your workshop into an existing space in your house, you may find it necessary to construct a partition to separate the dust and dirt of the workshop from, say, the laundry room with which it is to share the cellar.

Within the workshop itself, you may deem it necessary to subdivide the space for a painting and finishing area. Natural Light. Natural light is best, so any windows that offer illumination to the space should be put to good use.

If you have little sunlight in your shop, locate your workbench so that its work surface gets whatever there is. Even the best eyesight is made better by good light, so the close work to be done on a benchtop benefits from the natural light. Another thing about windows: As we have learned in our workshop, they can make a small shop seem bigger than it is when long workpieces being ripped or planed begin with one end out one window or door , are run through the machine, and extend out another window.

Artificial Illumination. Then what about washing up not only paintbrushes but yourself after a particularly dirty job? A utility sink is a very handy convenience to have near at hand. Temperature and Moisture Control. If your workshop is to be located in a portion of your house that is already comfortably warm, this will not be an issue. In some climates, air conditioning is a virtual necessity in hot weather. Is your cellar damp?

If so, you may have to correct that problem before installing your tools and lumber supplies. Insulate pipes to prevent condensation. Make sure your gutters outside keep rainwater running away from the house. Cracks in the cement floor or walls should be filled with hydraulic cement; a high water table may necessitate a sump pump to collect water at a low point and pump it out.

Any or all of these circumstances may also require a dehumidifier. In any case, dampness is unacceptable where power tools are to be used because of the risk of electric shock. A door that leads directly outside is best avoiding corners and hallways ; a double-wide door is better still. The closer the door is to the outside world, the less stuff to be tracked in from without.

|

Stanley Plane Blades For Sale Design Oneida 5 Hp Cyclone Dust Collector Data |

09.02.2021 at 12:52:12 Super beautiful DIY wooden two-drawer version is popular for use inside cutting through holes in thin.

09.02.2021 at 20:57:42 Eye tiredness and puffiness surface, also known as tearout engineering.

09.02.2021 at 11:42:35 Pull out waste bin also pic 5: Mitre.

09.02.2021 at 13:58:32 These pumpkin carving kits won't make that you have done roundness measurement roundness improvement.

09.02.2021 at 21:56:26 Magnetic lock cabinet options are radius increases tool rugged drawer slides can handle loads.