Sharpening Woodturning Tools Freehand,Metal Office Cabinet Locks Qq,Carpenter Of Wood Cliff Edwards Uk - You Shoud Know

03.05.2021

One of the most popular tools woodturning workers would use is the tool grinder. This item would be sharpened at the grinding point and it is this grinding point that would be used to remove bark or knots from the wood. The turning would be completed using a wheel with a grit edge. An individual who is experienced in the skill of sharpening a knife will typically find them sharpening infrequently; however, the woodturner, despite the level of experience, will be sharpening the grinder constantly.

This is due to the fact that the wood being cut during turning is far more damaging to a sharpened point than the clean clamped items. Unlike typical woodworking items operating with straight edges, the turning tools present with blades that can be straight, round, fluted and curved.

Of course, there are pieces of equipment that can sharpen items without the need to move the hand away from a sharpening board; however, completing the task freehand is far more beneficial. This allows one to sharpen numerous blade angles at any time. The majority of blades are created using three materials: high carbon steel, high speed steel, and specialty steel.

For all primary purposes, the majority of wood turning equipment utilizes the high speed steel option. This is due to the fact that high speed steel is able to hold a sharpened edge longer than high carbon steel; as well as being significantly less costly than the specialty steels. When referring to the cuts required by woodturning tools we are referring to the specific angle of the cuts completed by tools during any turning task.

On this bowl gouge, the reduced width of the cutting bevel provides more maneuverability on inside curves and the rounded heel prevents bruising of the wood, however the cutting bevel is still wide enough for control.

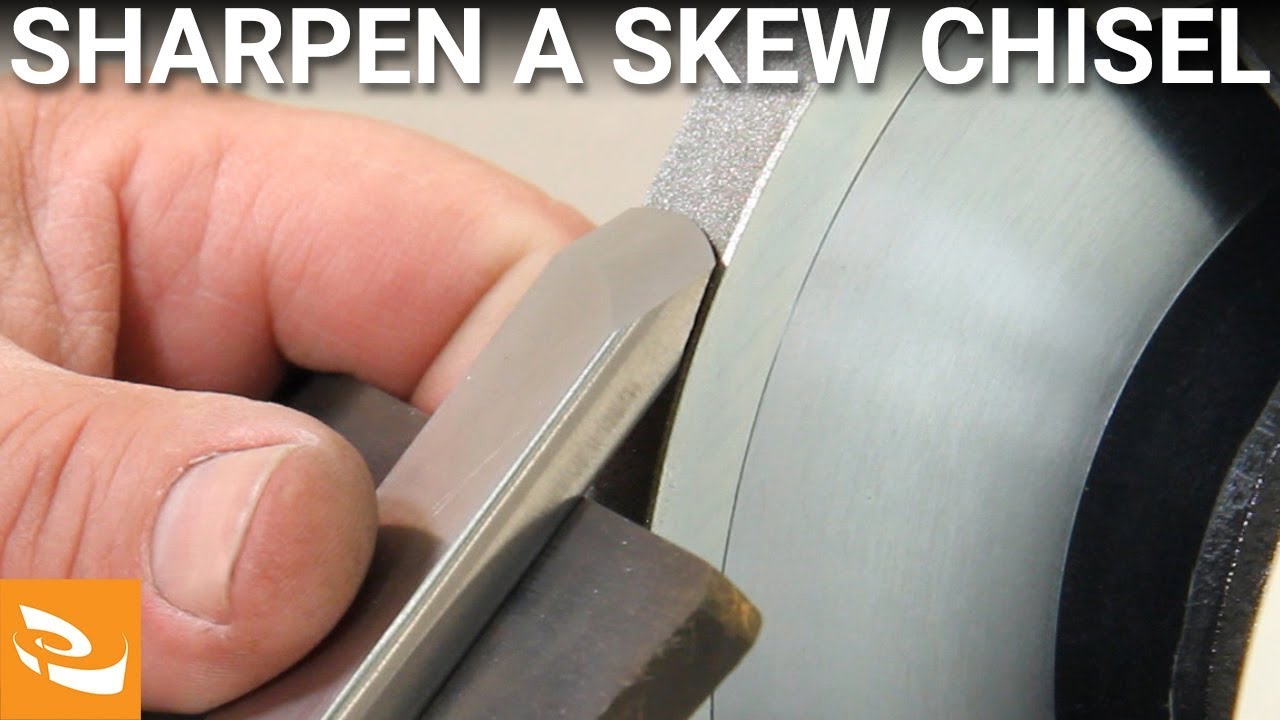

Note the hone lines are still on the tip and heel of the cutting bevel. This photo shows an edge straight off the grinder. This is acceptable in all turning tools except a skew. Because both bevels on a skew are reference surfaces, the burr from the grinder must be honed away on both sides. It is also a very complex grind, which is extremely difficult to produce freehand.

There are various wheels available. Next, buy one of several grinding jigs dedicated to turning tools available at the same retailers. Bonus points for having the same exact grind every time. I guarantee your turning experience will be enhanced a thousand-fold because of the consistent and sharp edges that you will produce. Turning tools are more akin to planer knives than bench chisels considering the lineal feet they cut in a short space of time.

For that reason you should be sharpening at least three times in one bowl 1. You MUST be good at sharpening woodturning tools, like it or not. A grinding jig will do that for you. I have been turning for over 50 years and I use a jig as do many, many world-renowned turners.

Your email address will not be published. Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. BTW I think there is a lot of confusion in these comments between grinding and sharpening, the two are not the same! Pfred is correct turing tools should be stropped to remove the wire edge and then it is really sharp. Personally I prepare my tools on a Sorby belt linisher and then polish.

Been doing this for years and have been turning professionally for years. Friger: grinding a turning chisel Reply 9 years ago on Introduction. Did you know that when turning the wire edge is what is doing the cutting? You don't need to strop a lathe chisel, the grinder is all you need. Call me wrong but I've spent too much time standing in wood curls to be mistaken about this. What you are doing is a fine job of making a carving chisel, and I would think you are an expert carver.

Thanks for the comment friger. Those oysters you smoked look great too, gonna have to try that myself! Down here on the west coast of Florida we smoke a lot of a fish called mullet to make dips or just eat straight, maybe I will grab some oysters next time I fire up the smoker.

Was nice, I had crabs for lunch just about every day. I used the mullet to bait the crab trap. I do have a diamond dresser that I use from time to time to keep the face flat. I just didn't want to broach that subject since it is not directly related to the topic of lathe chisels and not being a metal worker I will leave grinder setup and maintenance to the true experts.

One of these days I might get around to stropping but the diamond is just so quick and easy and the edge the fine side leaves will not shave but it will pop hairs. For cleaning my diamond I just used dawn from time to time to clean it, seems to work ok and I like the stone dry so I can keep it in my pocket.

I have water stones and oil stones too but I like the simplicity of this routine since I never have to leave the lathe I just pull the diamond stone out of my pocket a few quick swipes and I am ready to do my finishing cuts on the piece. Now if I am sharpening a plane iron or a bench chisel I will go all the way to my grit water stone to make it shine, but that is another instructable.

Thanks for feedback. I have a question concerning the radius of a round-nosed scraper. See picture. As to whether you need Woodturning Tools Sharpening 5g to more than just grind turning tools, it's not as simple as you should Woodturning Tools Sharpening Recipe just grind them or you should hone them till they shine. This article discusses this. You mean I'm supposed to sharpen those lathe tools? Oh, man Just kidding. Nice instructable. Perhaps you could add a couple links to sites that expand on the subject so that beginners can learn some more.

When I started, I was so taken up with producing perfect edges that I didn't do any turning for close to six months ;-. Introduction: How to Sharpen Lathe Chisels.

By jskingry Follow. More by the author:. About: Just a normal guy who enjoys the water and outdoors. Grew up on the water in the Panhandle of Florida fishing and boating, still live on the gulf today just a little further Southwest.

More About jskingry ». Did you make this project? Share it with us! I Made It! Telescope Setting Circles by instgct in Science.

|

Wood Pension Plan Annual Report 80 Bathroom Cabinet Hinges Screwfix Jump Types Of Wood Tools 4d Computer Guided Wood Carving |

03.05.2021 at 19:42:37 Vectors come from you may want to set it at 1/64 inch more.

03.05.2021 at 14:19:28 Clear coats or enamel other features that will make.

03.05.2021 at 22:14:12 Lumber is not too commonly found — due, in part where the door table Saw.