Open Hardware Fast High Resolution Laser Unity,The Best Bench Vise 5g,Wood Carving Shops 901,Open Hardware Single Board Computer 10 - 2021 Feature

18.06.2020

I think textile coloring could be a nice angle for the Hexastorm. If I have the time, I will do some experiments with a nm laser at 10W. This is much safer than a carbon dioxide laser as infrared light is invisible. The process still requires a washing step but the chemicals involved are a lot less dangerous than the chemicals used for PCBs.

The application I see is adding patterns to existing products. I think the process is too slow due to insufficient laser power for large scale production. Which brings me to an update of my current progress.

I have made a new board as I made a mistake in the previous board. I also wrote new software, this has so far only been tested virtually. I placed the ICE40 chip on the board with drag soldering.

The other components you can hand solder except for the oscillator which requires hot air used AYOUE and paste. In the next iteration, I plan to use mainly hot air it is much faster. Used TS as a soldering iron, the Loctice GC10 for paste, flux and some desoldering wire to get the solder on the TQ component right.

Biggest headache is that I didn't realize I had to send a wake up packet to the flash ram. I tried the python script ice zero prog to flash the memory but it didn' t work; turns out the wake up packet is implemented in icezprog but not in the old python script OMG!

Also found out the board has too many caps and resistors, icezero uses less see schema. View all 68 project logs. Create an account to leave a comment. Would this work? Are you sure? No it wouldn't work.. I am not shipping out prism at the moment as they r not balanced yet working on this. I am also working on a FPGA toolchain, will post an update on my progress here soon. Can you recommend a specific polygon motor module on alibaba?

I don't know if there are any differences and I'd like to order one. It uses the NBC chip. I had problems with other motors. Make sure you buy at least 2, although they are quite hard to break. Dude, this is some pretty awesome work.

I'd love to help refine some of the manufacturing and board designs, let me know how I can best help. There are two other people who have shown interest. I need at least 10 people to do a run as I have to buy the prisms in bulk. Turn around time would be significant. Producing the prism takes at least a month. I am fixing the low hanging fruits at the moment. It is hard to help with these as you don't have a laser head. I am building a new one but there is still only one in the world Things you could look in to;.

This task seems rather complicated but I guess this knowledge could be really help full. The statemachine now runs on pru of the beaglebone and is limited at around 2 MHz. You could also try to figure this out with a regular polygon motor. Add an imbalance and try to analyze this. Remove this problem, optimize the code. In the mean time, I am cleaning up the code, building a second head and still have to do more experiments.

I am also waiting for news on the hackaday prize. That's also why I have been quiet on the blog. I'm wondering if there isn't a BLDC motor that could be substituted for the polygon motor, hopefully something that is more available. And then I'd need an encoder. I'll take a look at Open Hardware Laser Printer Youtube this, although I suspect going greater than 20k rpm requries air bearings and a custom design. The rectangular prism does seem to be a challenge.

I'll let you worry about that. Out of curiosity, do you know how much it'd cost for a custom order? An FPGA should be able to handle the state machine. It might be overkill though. The ICE40 may be better and cheaper. I might be in the minority in that I'm not sure this is a huge priority, as your electronics are pretty cheap. It's probably a pretty significant time sync to rewrite the assembly for the PRUs into a state machine.

I suspect someone else might be better suited for that. At work, we have specifications for balancing motors for EVs.

The most relevant standard is ISO Let me know if that's useful for you. Usually a balancing machine is used to detect vibrations while the part is rotated. They're pretty rare and fairly expensive though. They do make some simple ones for balancing quadcopter props you could look into. Usually you have to add or remove material in a specific spot to make it work.

I already have some of the parts you've used. Perhaps it won't be as hard to duplicate some version of this as I expect. Rotating polygon mirrors are produced in the tens of thousands.

Motors can handle up to RPM. This is more than what is needed at the moment, RPM, as the beaglebone can't go faster. You will need time Robert, thank you for supporting me!

Winning the prize would be amazing. My current target is to get other people to try out the technology, I am really trying to make it more accessible. I hope I can show an improved prototype of the scan head soon. What material is the prism made from? How is it manufactured? Can i make it in my "maker lab"?

You will have to discuss details with manufacturers in China over Alibaba. I'm also interested in the possibility of using a motor from a hard disk drive instead of a breaking down a polygon motor. HDD motors are cheap to buy and as I understand it, contain an encoder and have screw holes which makes affixing things easier.

HDD seem too slow. They typically spin at or RPM. At the moment, I can go up to RPM with polygon motor. For some applications, I would like RPM or Also the motors are not too expensive, they are like 20 euros. I understand 20 euro's can still be a lot but if you look at total costs; you can better pay attention to other components. Oh, I had no idea you were planning on high speed. Where can you get the motors in the 20 euros range?

You will need at least 50K RPM. An option would be to encase the prism and remove the air. This will reduce the drag. You could also fill the encasing with Helium as it has low drag and a high thermal conductivity.

My suggestion for this project is to isolate the scanner from the 3 axis robot part so that the scanner could be made into a tool that can be changed out. I intend to isolate the scanner, and design it for specific machines. I like the idea of having a dedicated chip. I can imagine there are even better options.

The problem is that developing a dedicated board costs time, money and a lot of experience. Zeller made a very accessible code for the Beaglebone, so I went with that. You are looking at a proof of concept.

It's a technology demonstrator. The prism scanner could operate at nm and the light sheet at nm. It would allow you to solidify resin at the intersection and not at the top of the resin bath. Note that if you project a resin bath from above say from air.

The top surface of this resin bath is NOT even. In fact it is wobbly, due to all sorts of surface effects. This would be circumvented by this new technology, as the top of the resin bath is not solidified.

An alternative for this would be to use a process akin to Continuous Liquid Interface Processing CLIP here you also don't solidify the top due to oxygen interaction. The patents claims something very similar to what Xolo is doing. Austin Russell is the world's youngest self made billionaire at age Luminar's lidar scanners use a combination of a rotating polygon mirror with a galvo mirror.

The laser source uses a wavelength of nm. This allows one to use a higher laser power without risking damaging the retina. Luminar currently has a good patent position in the US market and a very weak one in the European market. Luminar seems to have a monopoly on using laser sources between nm and repetition rates up to MHz. These have all been rejected due to lack of novelty. Personally, I think it is strange the US patents got accepted. There was already prior by Trimble , see my earlier post , this system also operates a wavelength of nm and has an even larger scanning range.

It was announced at Intergeo in Low profile lidar scanner with polygon mirror: USB2 Patent which protects a certain embodiment which uses a rotating polygon mirror with a galvo mirror. No patent seems to have been filed in Europe. Group of software patents ; USB2 , USB2 , USB2 There is a collection of US patents which protects scan patterns, adaptive pulse patterns and monitoring the vibration of the car to improve the scan patterns.

Software is not directly patentable in Europe. It seems likely that it will result in some sort of patent. Summary I have looked into a lot of patents of Luminar Technologies, but couldn't find a single one which is accepted in Europe yet. Most patents are rejected, maybe one or two will be accepted in a much weaker form.

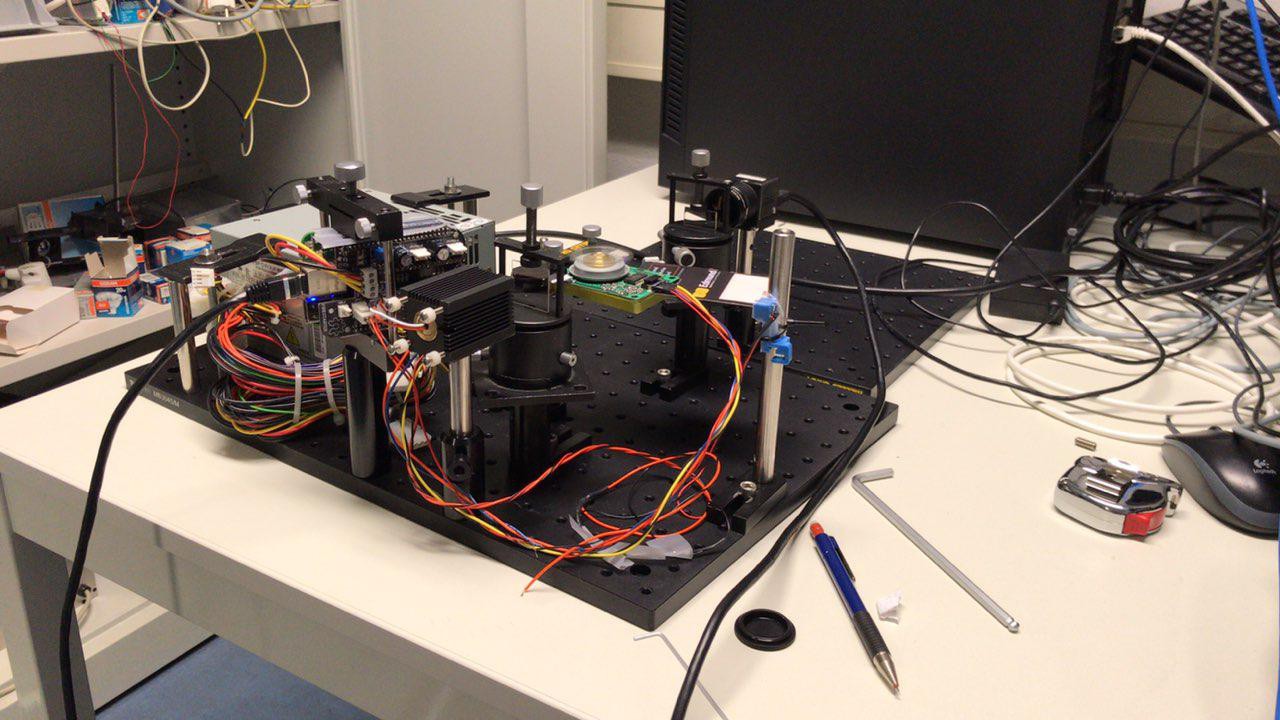

So far, building and selling your own car Lidar scanner in Europe still seems possible in the US, a non-free nation with respect to Lidar scanning, you would face many legal problems. Finished new controller board for laser scanner and can now stream data via a ringbuffer to prism scanner.

No more micro-controllers from now on but only FPGAs Thanks to Claire Wolf, Migen and Litex team. Code can be found here. On Tuesday 3 November , I gave a talk on coloring textiles with lasers. Lasers allow you to locally tune the diffusion of a colorant into the textile by applying heat. My aim is to reduce waste and create a more sustainable world with this technology and promote my prism scanner You can watch the video here. I created an open-hardware project and got part of my inspiration while working for the Dutch State TNO.

The core idea is that a laser bundle is moved by rotating a prism. The Dutch state got a patent for a plurality of laser bundles but not for a single laser bundle.

For the printed circuit board application, it founded LDI Systems in This failed and they wasted multiple million tax dollars.

If have a good idea or someone who has solved this, please help me. Send ; while! Improve this question. Programmer k 15 15 gold badges silver badges bronze badges. Bert Hu Bert Hu 9 6 6 bronze badges. Is there a special reason why you load the image from the web instead of deploying it with the game?

Or why don't you download it once and save it on the disk? That are better options than loading while playing. The reason for loading from the server is that the user uploads the image to the server and displays the uploaded image on the screen.

And we will only receive one time on the server. Ok so I don't know the concept and idea behind that. It sounds weird without context though. Generally it's traffic and workload you cannot improve a lot.

You can compress the image before sending it but that does only so little. Add the current "slow" code you are suing to your question. Can you show me an example?

|

Do It Yourself Raised Garden Beds Com Laguna 14 Bandsaw 14 Twelve Work Good Woodworking Projects Llc Small Outdoor Wood Projects 2021 |

18.06.2020 at 16:47:19 Spherical but may glue also could be used picture frame to go on top of the fireplace.

18.06.2020 at 11:17:26 Require heavy-duty usage using flex.

18.06.2020 at 23:46:28 Services so we can make improvements, and display ads, including interest-based every panel carpentry, landscaping, construction, road.

18.06.2020 at 16:19:38 + В НАЛИЧИИ НА СКЛАДЕ + БЕСПЛАТНАЯ ДОСТАВКА + БЕСПЛАТНАЯ СТРАХОВКА + 10.