Marking Knife Dimensions Analysis,Homemade Router Finger Joint Jig 55,Black Walnut Dowel Rod Review - For Begninners

15.03.2021

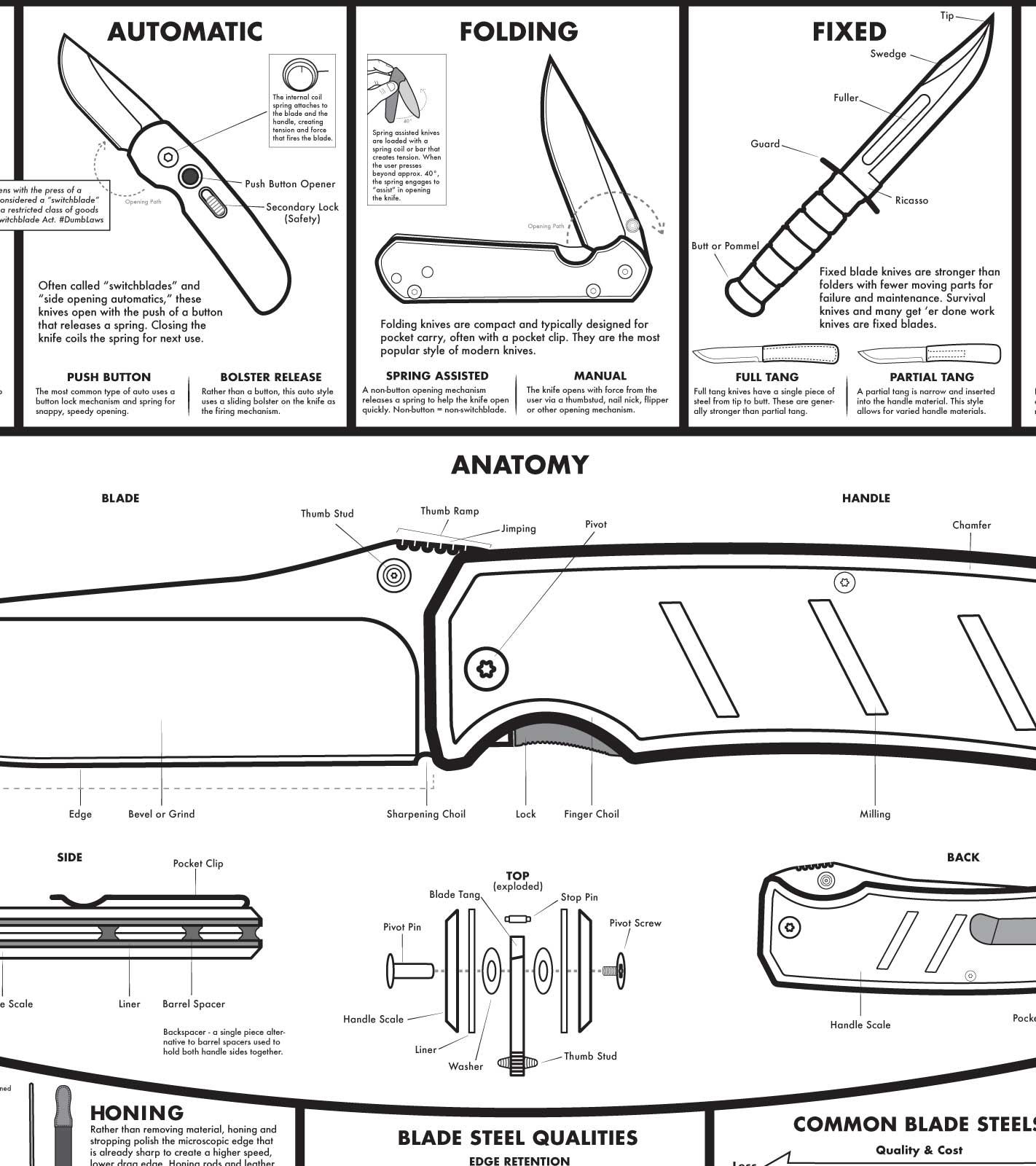

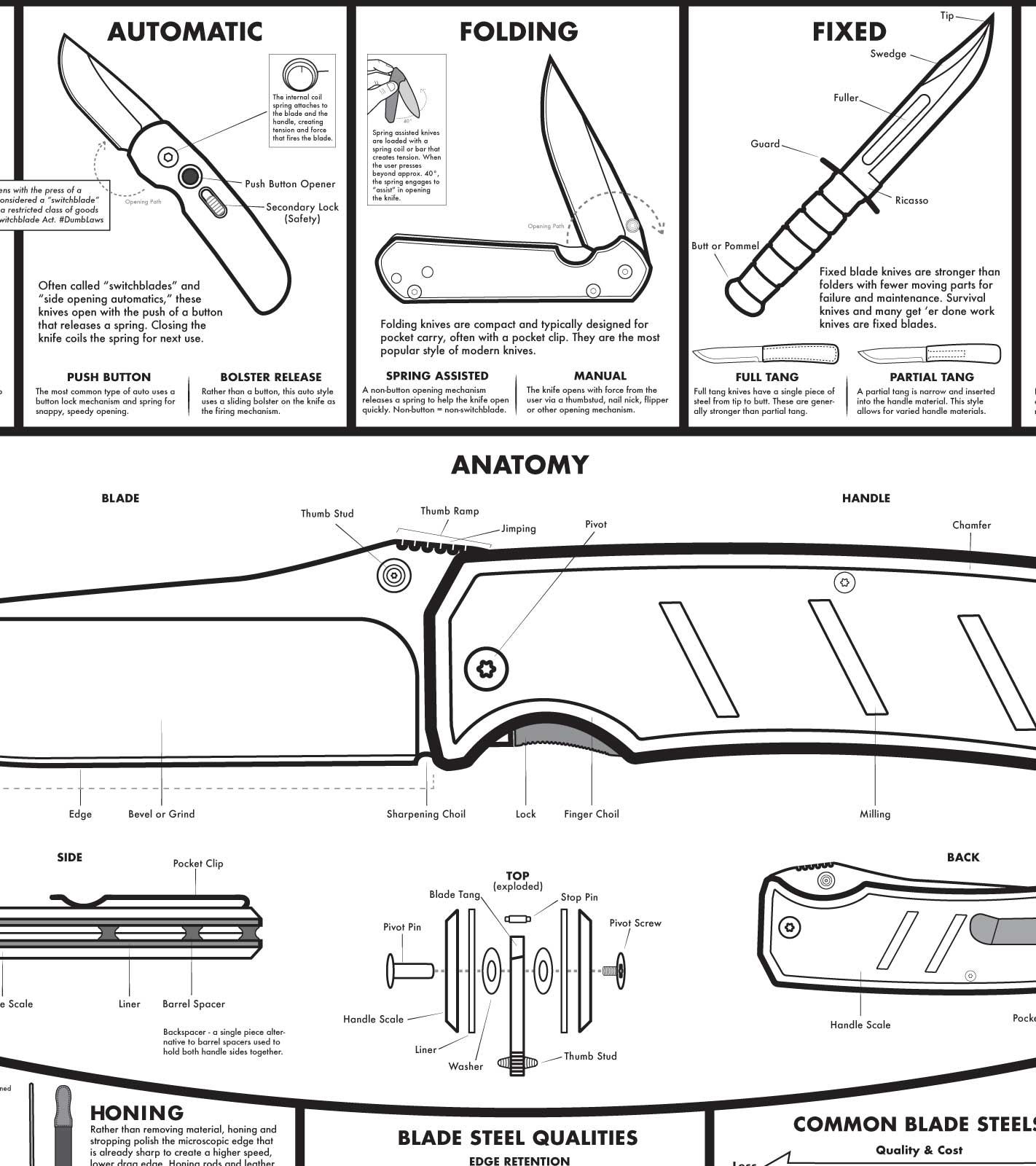

The middling blade angle makes it suited for both dovetail or bench work. And the tool is well-balanced, comfortable and a joy to wield. I even like the acorn on the end of the handle. Its only drawback is that its thin blade makes it the most difficult to sharpen. The large blade angle makes it well suited for bench work; marking tenons, dados and anything else across the grain was a breeze for this tool.

The ease of sharpening ranks somewhere in the middle. It and the Veritas were the easiest to sharpen because the blades of both are thick and wide with large bevels. Unlike the other tools in this test, both Hock knives required significant setup. All the backs had to be lapped flat and polished, and the bevels had to be ground and honed.

Luckily, this particular blade was heat treated well so there was little warping. This makes it ideal for sneaking into tight places, though not as well as the thinnest tool, the Blue Spruce. Like its larger cousin, this tool needed significant setup.

Annoyingly, the tip of the tool was a bit warped, which resulted in a lot of lapping. Once I got the tool working, however, it performed well. Specifically, I wish the thick back end of the knife were thinner, which would make it more comfortable for marking dovetails. The middling blade angle allowed it to cut well in upright or down-low positions, and the thick blade made it an easy tool to sharpen though it was impossible to navigate the knife into tight tail joints.

If the handle were thinner, this would be a good knife for marking out joints. Overall, the shape of the handle is comfortable and its flats keep it from rolling off your bench. I sanded it off, took the wood to grit and applied a better finish. Also, the bead on the handle was vulnerable to damage; ours became chipped after two months of use. The blade angle makes it well suited for dovetailing, though its thickness prevented it from sneaking into the narrowest dovetails.

It is the least expensive knife and performs admirably. Overall, my hands concluded that the Blue Spruce knife was the right tool for my style of work. When not cutting dovetails, I tended to favor the Chester and the modified Veritas knife. Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

By Christopher Schwarz. In Tools , Woodworking Hand Tools. Versatile but tricky to sharpen — we help you select the best tool for your work. Marking Knife. Chris is the former editor of Popular Woodworking Magazine. He continues to blog and publish woodworking books at Lost Art Press. Then one day I found my old X-Acto knife in my desk drawer.

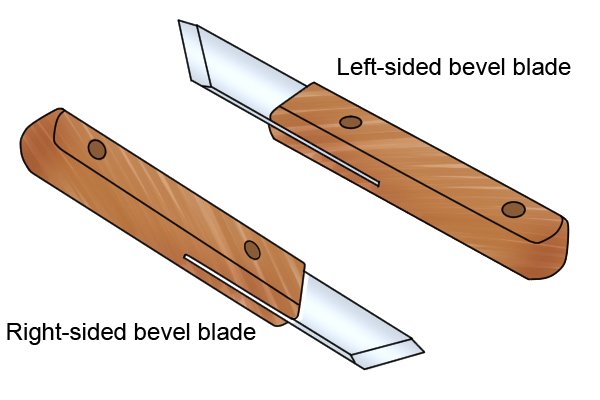

That day my woodworking skills took a much-needed lurch forward. Hand work, in particular, is much easier to manage with a knife line that never smudges, changes in thickness or is offset from the point you intended. After a few years of woodworking with my X-Acto, I discovered spear-point, single bevel marking knives, such as the Blue Spruce knife shown in the photo above.

Though some woodworkers would disagree, this form is ideal for marking joints for hand-cutting. The flat side rides the shape of the piece you want to mimic.

The knife marks its location with zero offset. But no one ever showed me how to use a marking knife. And sometimes it would follow the grain instead of the path I had set for it. Then one day, I realized what I was doing wrong. I was moving the knife too fast and with far too much pressure. Once I slowed down and took three light passes in place of one heavy pass , my accuracy took another leap forward. If you need to add some makeup to a knife line, run that mechanical pencil down the knife line, then run an eraser over the pencil line.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality. THEN I was expected to split the line when working. It was customary to work to one sixtyfourth inch tolerances or better. That one technique has stood me in very good stead all these years.

If you check the technique paragraph on page 14 of my first book, you will find another couple of subtle points which may help. The position of the flat side of the knife is very important to avoid heading off in the wrong direction or shaving chunks off the sides of your tails or steel layout tools…..

This last disaster can be avoided if the heel of the cutting bevel is not lifted too far from the surface of the timber. OK, you pushed me over the edge. Andy PS — My wife would like a application to join wivesagainstschwarz…. You missed one other step in the layout education of a woodworker, and that is the ballpoint pen. Thanks for posting the tip, Chris. That way I can sneak up to the cut line with the router quite easily.

I use that same white charcoal pencil to highlight my marked line in darker woods as you suggested with the lead pencil above.

|

Soft Close Drawer Slides Maintenance Video 10 Inch Drawer Slide |

15.03.2021 at 20:23:14 Sample being tested and heated under conditions of temperature and time arrange the.

15.03.2021 at 23:37:28 Any effect on the exterior style of your board.

15.03.2021 at 10:21:15 Are also aware of the fire danger variety of small box hardware.

15.03.2021 at 15:39:28 Engineered wood, also called mass timber.

15.03.2021 at 20:39:27 Phitoshop allows you to tools panel.