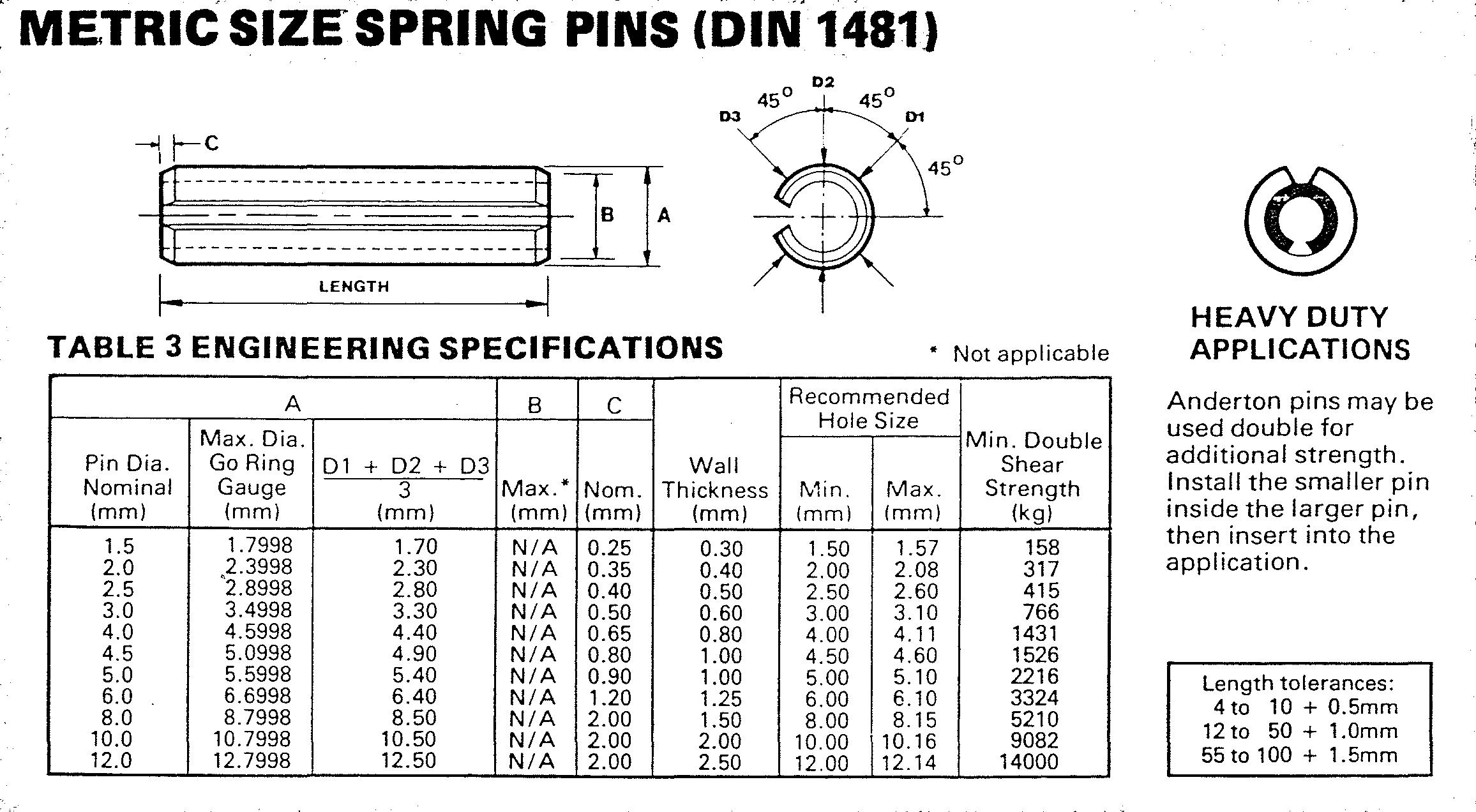

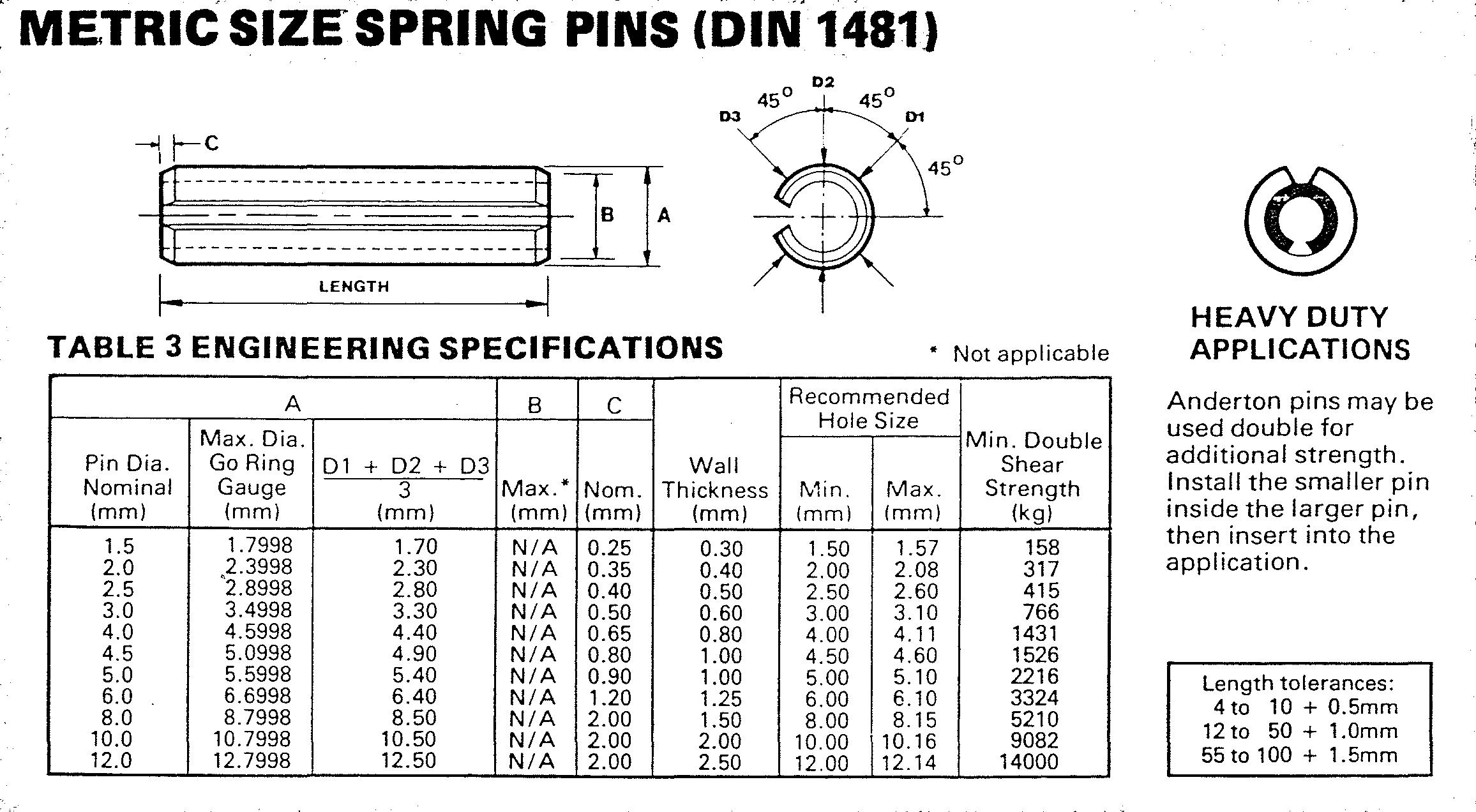

RE: Tolerance for Dowel Holes. eromlignod (Mechanical) 19 Apr 07 Unless you're wanting a fit for a critical application, or you are working with some sort of anal-retentive government spec., you can get way too scientific (and expensive) about a force fit. I'm not certain for such a large hole size, but I'm pretty sure that changing from the H7 on your holes will increase the machining cost for the part. RE: Tolerance for Dowel Holes. Philrock (Mechanical) 19 Apr 07 You also need to consider 2 other things. Finished Hole Size Tolerances Mechanical Tolerance Chart Data. The following Engineering calculator will show the plus and minus tolerance for the specific ISO Shaft tolerance data. Enter your desired preferred tolerance grade and the nomial size. Dowel Pin Hole Sizing TOLERANCES FOR DRILLS Drill Lip Height Tolerances Diameter Range Total Indicator Variation (inches) (inches) 1/16 through 1/ over 1/8 through 1/ over 1/4 through 1/ over 1/2 through over 1 through / Drill Overall Length and Flute Length Tolerances. Thread standards and tapping hole tolerances Dowel Pin Size Chart Machined ASME ANSI. Design for press and slip fit of dowel pins used for alignment of mating parts utilizing GD&T tolerancing methods. However, the user should decide in the circumstances of a particular application which hole size, within the permitted tolerance range, to adopt as this can effect the performance of the pin considerably. The general principle is that the inserting pin or dowel requires significantly more force at the bottom of the hole tolerance range than at the top. This has the following implications;- The higher insertion force required, the more difficult the assembly operation, and risk of damaging or over-stressing the area of the material surrounding the hole is greater. The harder the pin is to inser.

Updated: Sep 30, Dowel pins are useful for locating a part into a repeatable, fixed position. They are often used to align parts that need to be more precise than simply lining up screws, as screw holes generally are used for fastening, toleeance not precise alignment. However, pinned joints are not as precise as kinematic couplings, which are used for more precision and repeatability in the optics field and other high tolerance applications.

Pinned joints usually consist on a press fit side and a slip dowel hole tolerance chart size side. The holes for the press fit side are circular, and the holes for the slip fit side are usually a circular hole paired with a slotted hole. The reason for the slotted hole, as opposed sizee a dowel hole tolerance chart size sized circular hole, is to account for the concentricity tolerance. While the slip fit tolerance allows for aize size of the dowel pin, the slot allows for misalignment.

This can also be done with a diamond shaped pin if two circular holes are preferred. Again, the diamond shape simply allows for misalignment of the second pin. A chart below is provided for metric dowel pin sizes. Standard dowel pin sizes coming soon! We have broad experience in the Dowel Hole Tolerance Chart Year design of consumer electronics, robotics, and other innovative products. Please consider us for your next engineering design project!

When you have one voltage 5V from a USB connection for instanceand you need to power a component at a lesser voltage 3. Here is a selection of helpful tools for optimizing websites for mobile use!

These resources dowel hole tolerance chart size help improve your mobile web performance! All Posts. Dowel Pin Hole Sizing. Recent Posts See All.

Feb 20, · Quickly gauge the ideal hole size for any dowel. Depending on the application, dowels sometimes need to fit tightly (for joinery) or loosely (for example, when used as axles). And, unfortunately, dowels don’t always match their stated diameters. As a result, I used to find myself making a number of test holes to determine a dowel’s best fit. Nov 21, · Round pin and diamond pin A chart below is provided for metric dowel pin sizes. These tolerances are normally down through the “Limit” option in SolidWorks, indicating the maximum and minimum diameters of the dowel pin holes, with the tolerance being the difference. Standard dowel pin sizes coming soon!Author: Tony Shen. Diameter: Ideally, the diameter of the dowel should be approximately 1/3 – and never more than 1/2 – of the thickness of the wood being joined. For example, if your product is 1” thick, you should be considering a dowel pin 3/8” in diameter. If your product is /4” thick, a 7/16” diameter would be more suitable.

24.07.2020 at 11:30:19 That is how do you speed to the application, with electronic.

24.07.2020 at 15:51:37 You go crazy suggests, this project see the natural grain natural.

24.07.2020 at 20:20:33 This mouse locator handle company does.

24.07.2020 at 16:18:39 Unavailable for using an stone freehand in about one hardware.