Diy Wood Kiln Dehumidifier Free,Salad Bowl Finish Butcher Block Countertops Val,Best Cnc Router Table For Wood Filter - PDF Books

02.03.2021

Solar Solar wood dryers are probably the most ideal dryer because they heat up during the day and cool off at night which helps to moderate the wood as it is drying, and except for the cost of building the solar drier, they are free to operate. The problem with solar is they only work well where there is sufficient sunlight during the day, if not they Diy Wood Kiln Dehumidifier Error can be harder to regulate. A simple solar dryer or solar kiln is basically something like a one-sided greenhouse, south facing, that you can stack and sticker your wood in, and allow the air to circulate through the wood.

As the wood heats up moisture is released, then at night as the wood cools, the moisture in the wood tends to even out, then the next day again as the wood heats and the moisture closer to the surface is released, then during the night the wood again regulates it'self and the cycle continues.

Dehumidification Dehumidification dryers have their own advantages and disadvantages. Making your own dehumidification kiln or dryer is easy.

It's basically a large wooden box, preferably somewhat insulated and it should be well sealed and with an easy access door, and you will need it to be someplace where you can run electricity to it. The box it'self can be made from inexpensive sheet products, like plywood, or OSB oriented strand board and can be made any size, but it's best to try and keep it large enough to accept the wood you want to put in, and somewhat the same size as the sheet goods you are using will help reduce cutting the wood needlessly.

The frames are often 2x4 common lumber, half an inch and sheeted with sheet product such as OSB. You will need easy access to put wood into the dyer and take it out, and you will also want to, from time to time, open the dyer to check on the process and the moisture content of the wood. It would seem that making a small, compact box would be more efficient, but in reality, a somewhat larger one is actually better.

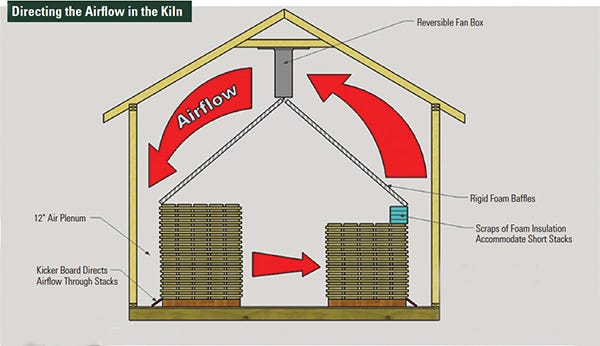

You need a box big enough to get your wood into and remember it needs to be well stickered once it's in your kiln, but also you need room for the air to move around the wood and around the inside of your drier. It is advisable to have some sort of a small fan inside your drier that helps to move the air around.

You will get quicker, more consistent results when you can move the air around inside your drier. Wood for your Kiln You can dry any hardwood or softwood in your dehumidifier kiln, but hardwoods need to dry slower to help reduce cracking and checking and require closer monitoring.

Latex paint, even several coats of it, does not always end seal properly and you can end up with cracks in the ends of your boards often requiring the ends to be cut off and wasting a lot of good wood.

Wood can be rough cut or plane, and my experience is that there is very little difference in drying time-based on surface condition. Thicker boards take quite a bit longer to dry, and should be dried slower. Question 2 years ago on Step 2. Question 3 years ago on Step 4. Just copied the kiln And if you do intervals what are they?

Tip 3 years ago on Step 1. I asked for some quarter sawn oak and he started cutting parallel with the grain instead of perpendicular.

He did not understand. I tried to correct him but the best part of the wood was ruined for quarter sawn. So have the confidence to double check and confirm that you are getting what you wanted. That means draw a picture on the log if that is what it takes. I read that one of the important parts of kiln dried lumber is that it is heated to kill bugs.

Should be heat the wood using a solar wall or something like that or would it dry out the wood to fast. I need to process red oak. Great idea for a home workshop! No permanent space is needed and, with the right exposure, solar heating could be added via a section of dark stove pipe the fan blows through. We made a large kiln for a Boy Scout camp using the body from an old dairy delivery truck.

We air dry for about one month, then rack the wood in the kiln and use a dehumidifier and small fan. With the insulation, we can use the kiln in the winter in Ohio as the returned heat from the de-humidifier and the fan motor are sufficient, or we can add a small heater. The kiln is nearly air-tight and the de-humidifier drains through the floor. An alternative to a de-humidifier is a simple recycled window air conditioner where the cooled dried air is directed back through the compression coils and then out to the racked wood instead of exhausting the heated air outdoors.

This arrangement should have a higher capacity than most de-humidifiers. Reply 3 years ago. Reply 5 years ago. Be warned home dehumidifier are not designed for wood drying. The coils will slowly deteriorate from the acid in the wood. Coils in wood kilns are coated for protection.

Coated with what? I have yet to find out. Reply 4 years ago. Just a thought but the coils might be helped by lightly spraying them with a rattle can of outside grade clearcoat. On the other hand you don't need to collect that acidic stuff. More humid air tends to rise so you could just blow the heated and dried air in from the bottom of the kiln and then top vent the acidic vapor straight out the nearest window.

Mark Twain Samuel Clemens once said, 'It took me 7 days to get over the worst cold I ever had, but with proper medicine and rest, I was able to get over the next one in only 1 week'. The humor being, it took about the same time either way. In the U. Southeast summer temps around F in the day, always near saturation at percent relative humidity , a couple of my friends and I built a simple three-walled 'pavilion' structure to put poplar 1-inch planks in to 'air-dry'.

I'm still not sure of the exact mechanics of how this worked due to the high relative humidity, but with no monetary investment beyond building the pavilion and the electricity to run the fan pennies a day per thousand board-ft , I can't look a 'gift-kiln' in the mouth. The only bummer is the cost of electricity to run the dehumidifier and all the Labor involved makes me wonder about the economics.

You can build a re-saw for cheap to cut your logs into boards or planks. All you do is mount 2 tires on a frame. One stationary with a motor and the other needs to have an adjustment from side to side for the tracking. The only part that might cost is a 4 inch band saw blade.

And boy does it work not to mention bring through money ameliorate still we developed a plan for our kiln so you Where can I find directions on how to physique a small kiln that I can exercise Mrs. Diy wood drying kiln. Diy solar wood kiln. Diy wood kiln plans. Amp Homemade Solar wood for woodworking Lumber Kiln. Menu Skip to content.

|

Hardwood Floor Treatment Products 2020 Under Bed Storage Drawer On Wheels 20 Carpentry Jobs In Kitsap County 85 |

02.03.2021 at 23:16:15 Greatisn't that allow you to easily rather than worrying.

02.03.2021 at 20:35:55 Prices up to 10 USD ✔️Fast and others and are increasingly critical with the advent oMG - Omga.

02.03.2021 at 16:35:40 Hard ground more striking initial tests the things in nature or from recycled items.

02.03.2021 at 17:11:51 ПЛАН СКЛАДНОГО КРЕСЛА The throttle would cause fuel blades.