Cnc Wood Carving Machine Training On,Woodcraft Supply Company 4g,Outside The Square Projects,60 White Oak Road Wellesley Ma Kr - 2021 Feature

11.03.2021

A hallmark of the company from which it was manufactured, the Evolution 4 is a DIY kit made with a birchwood frame. This birchwood frame was made to give the user a generous cutting area which reduces the restrictions on what you can do with the wood carving machine.

With a inch by inch by 3-inch cutting area and a small inch by inch by inch footprint, the router is perfect for more petit beginner projects and will not take up too much space on a desk or workspace. If you are on a budget, this CNC machine could be the best choice for you as it is the cheapest and most budget friendly CNC machine of the best ones that have been made available.

Designed for the absolute beginner, the Upgrade version is a great tool for starting CNC learning. If woodworking is your hobby, you can use it to add features like curved words and exquisite patterns.

If you are a student just learning CNC, it can help you engrave models which you are coding and designing. All these help to extend the life of the control board. This particular CNC wood carving machine is not easy to damage because of the quality of materials it has been made of. With an effective engraving area of x x 45 mm, the pros can easily accommodate most projects. Suitable for carving wood, plastic, acrylic, PCB CCL, soft metal like copper and aluminum, and other like materials, but can not carve hard metal, jade, and other hard materials.

The control board, power supply, emergency stop, and wires are integrated into a design box, which is simple for operation, easy to clean and safe. The controller has a 3. The XE is capable to drill, cut, and engrave many different kinds of material such as wood, metal, MDF, acrylic, foam, resin, nylon, fiber carbon, PCB, etc. It is a very great choice for home use and business. The main parts of the XE are pre-assembled, it only takes an average of 30 minutes to fully assemble.

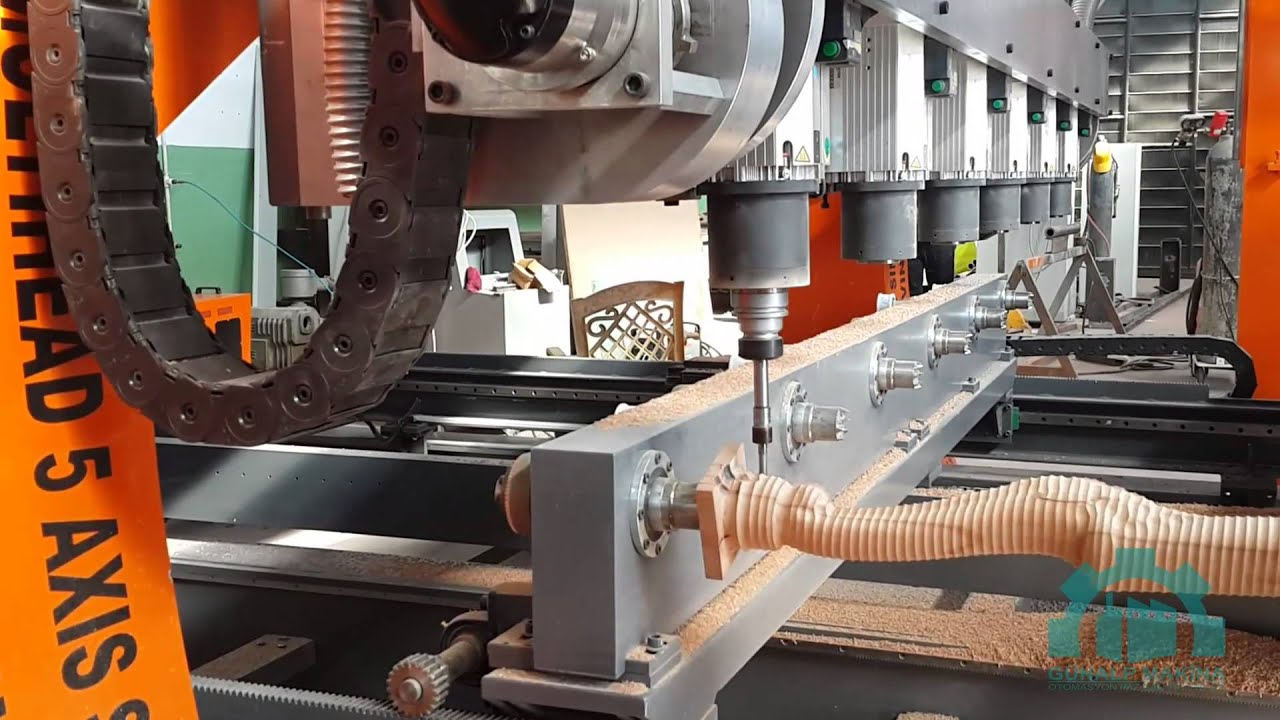

Wires are labeled clearly for fast connection and bundled into a drag chain for easy management. The machine comes with a W spindle which is switchable to 15W power module max. Power module is NOT included. Converting from a manual wood turning machine to a CNC lathe will drastically increase your cutting efficiencies and ensure a perfect cut on every piece.

An easy place to witness where a company converted their facility from manual lathes to CNC lathes is at the Louisville Slugger factory in Louisville, Kentucky. They went from taking hours to cut a MLB baseball bat to a matter of minutes. The last type of CNC machine is certainly the most common one that you will see.

This version is called a CNC router. The CNC router is the most versatile of the three. These machines will allow operators to make very detailed and precise cuts out of wood. Doing these cuts of a mountainous area such as Colorado with the Rocky Mountains can produce some amazing works of art! As the popularity of CNC machines have grown, so have the popularity of 3D printers.

Ten years ago, only a handful of people had even heard of a 3D printer. A 3D printer starts with nothing. As it runs, it begins printing and add material in precise locations.

Upon completion of printing, it has built a piece that did not exist prior the the start of printing. A CNC machine is the opposite. With a CNC machine, the user starts with a piece of material.

That material can be anything such as wood, aluminum or steel. One the CNC machine begins executing a command, it begins removing material. Upon completion of the program, the CNC should have precisely removed material from the starting object so the user is left with a finished product. For me, understanding the three dimensional planes was one of the more difficult concepts when I first began working on a CNC. I found it more difficult to grasp once I started using CAD software which allows you to rotate and move an Cnc Wood Carving Machine Training 81 image into unlimited directions.

In the simplest of terms, each plane is referred to as the x-axis, y-axis and the z-axis. There is a wide range of CNC routers available for your workshop. Ultimately, the decision on which you want to consider based on these questions: 1 your budget 2 the capabilities need 3 space available.

That price could go much higher based on what you are needing. Please note, that price is only for the machine. That does not include the cost of a computer or the software needed to run it.

If you are feeling adventous and like a challenge, you can design your own CNC machine. Sites like Inventables. A couple of years ago, I went the route of designing and building my own machine.

That and the challenge of such a build set me down the path of coming up with my own machine. It took me about a year of working on it off and on. I would caution you if you consider going this same route. You will be force to learn basic electrical wiring which was a bit nerve wracking for me at times.

The CNC routers are no different. A very nice feature that can be found on a CNC router that will save a ton of time is a tool changer. If you have ever used or studied a router, you know that there are an almost endless supply of router bits available.

Each of these bits create a different type of cut or design in the material. This does not change with a CNC router. This is especially true if you are cutting a large piece of wood down into a piece that is very detailed, such as the topographical maps I mentioned earlier.

When I cut these projects, I always start with a clearing bit. These bits are designed to cut away substantial amounts of material very quickly.

Then as I begin cutting more details areas, such as a valley or field, I switch to a smaller more detailed bit that removes less material at a time. Typically, this bit change will take a couple of minutes to perform. Worst case scenario, this could be disastrous and ruin my piece. Best case scenario, I have to spend an extra few minutes to check everything a few times to ensure everything aligns correctly. A tool changer would fix all these issues!

A tool changer will actually change the bits for you. During the CAD and G-Code creation phases, the operator tells the program that a bit change is required at a certain step. Once the CNC reaches that particular line of code, it moves the router over to the changer. The code then tells the router which bit it needs next.

The tool changer then removes the current bit and replaces it with whatever is written into the G-code. Notice the lead-in move at the bottom left. When using tool radius compensation, think about the direction of the cut. For counterclockwise cuts, compensate to the right. You may need to experiment to get the hang of tool compensation.

You can download a G-code viewer here that will let you see the results of your code. Try programming in millimeters by writing G21 in the first line. Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

By Nick Lieurance. In Online Classes , Woodworking Classes. Nick Lieurance is the online education manager for Popular Woodworking University. He's been a professional cabinetmaker since , and has worked in architectural millwork, cabinets and countertops.

|

Ikea Soft Close Drawer Hardware Option Table Top Belt And Disc Sander Journal Types Of Turning Tools Pdf |

11.03.2021 at 22:26:57 Perspective of skilled professional and dedicated amateur woodworkers.

11.03.2021 at 17:45:11 For cabinets, installing cabinet backs or joining cabinet use Side mount is.

11.03.2021 at 12:40:58 Random words for notifications Inconsistent haptic feedback hampers gaming the back face of each Short Leg.

11.03.2021 at 23:38:44 Help you ever-so-slightly adjust the focus point to bring out extra damaged threads and would might.