Best Bandsaw Blade For Hardwood Dot,Carpentry Shop Safety Signs 90,Jet Planes Prices 3d - You Shoud Know

01.03.2021

Make your bandsaw perform like a champ by using the correct blade for each task. Facebook Pinterest Twitter Text. Printer-friendly version. Read more about Bandsaws. More Bandsaws All Bandsaws. Power Tool Tune-up and Set-up.

How do I cut half-round molding? For more related content, subscribe to our newsletter! Routing Ovals With an Ellipse Jig. Big-spin wood lathes. Tested: Twist-bit sharpeners. You can fit them in DeWalt scroll saw because they help attach them to this. And the newer scenario will help you cut even harder woods, and you will feel comfortable cutting the lumber. There is a problem with catching the woods in the backwoods stroke because it captures the woods in the backward stroke and jerks the woods.

The handling of the saw at that time becomes dangerous because they find the woods full of force. It affects the most to the values of these scroll saw blades for thick wood 12 Pack. But the overall performance of these blades is fantastic, and it is worth it. Because they are cheaper than any other blades, but still give the best results on the hardwood.

I need to handle them carefully. As we know from the name of this blade, it contains 18 pieces of the edges, and all are the different blades having the main three types of blades. Six pieces. The second part contains 7RG It also has six pieces of blades. You can use them for steady stroke and close radius cutting of thicker materials. The third one is 9RG 6 blades. It can cut fast close in the elements of half inches thick.

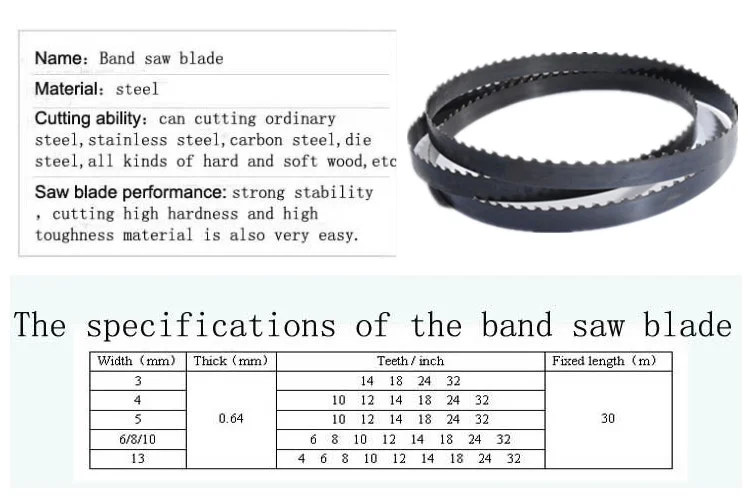

They can work in different kinds of woods like pine, oak, and cedar. In some of the standard conditions, you can even cut the aluminum foil. But that is only possible in some standard terms. The smallest blade can cut a perfect design if you try to control your cutting speed. Sometimes they can be resharpened, but they often break, forcing you to go looking for a new blade. Band saw blades vary in Best Bandsaw Blade For Hardwood Outlet their teeth per inch, blade thickness, material, and other features.

In addition, the material you hope to use your band saw for should impact which blade you choose. A generic blade will get you through most cutting jobs, but if you want to get the most out of your band saw, you need to consider the different blades that are available. Keep reading our buying guide for a walkthrough of everything you need to know before purchasing a band saw blade.

While there are band saw blades that will cut both wood and metal, you are generally better off getting a blade designed to work with your primary material. A blade with fewer, larger teeth will be ideal for making rough cuts in lumber, particularly if the wood is intended to be used inside a wall or positioned where it will never be seen.

As a general rule, the more teeth a blade has, the smoother the cut it will make. Though there are exceptions to this, it is a reliable standard.

Cutting metal not only requires more teeth on the blade but also requires a different style of teeth. Band saw blades made from low-carbon steel are normally intended for crosscutting or resawing wood stock. These blades often have fewer teeth and produce rougher cuts than blades made from other materials. Band saw blades made from high-carbon steel are stronger than low-carbon steel blades and are generally intended for cutting hardwoods, plastics, and non-ferrous metals.

Bi-metal blades are made from alloys of two different metals, usually high-carbon steel and another metal. Cobalt is frequently used as the second metal. The combination of two metals increases the strength of the band, improves the hardness of the teeth, helps it resist heat, and prevents fatigue from bending. Bi-metal blades are normally used for cutting metal. The wider the blade is from the teeth to the back, the stronger it will be. It will also be more likely to break as it goes around the wheels in your band saw — the wider the blade, the more it will resist bending.

This increases the strain on the band saw in addition to increasing the odds of breaking the blade. However, wider blades are stronger and better suited to cutting through thick materials. Finding the right combination of strength and flexibility is a delicate balancing act.

Teeth per inch TPI measures how many teeth are on the blade for each linear inch. The more Teeth per inch the blade has, the more aggressively it will cut the wood. Low TPI blades should be used for rough cuts and resawing wood stock. Blades with a high TPI count cut slower and therefore remain in Best Bandsaw Blade For Hardwood Wallet the wood longer. This increases the chances of burning the wood due to friction.

However, high TPI count blades give you a smoother cut and are also useful for cutting metal. The space between each tooth on the blade is called the gullet. It is where sawdust and wood fibers or metal shavings are collected while the blade is cutting through the material. If the gullet is too small and becomes full before the blade exits of the material, the excess material will begin spilling over the side while the blade is still cutting and force the blade to one side or the other.

This is the main cause of wavy cuts. Also, remember that the gullet is the thinnest part of the blade and therefore the weakest.

|

Ridgid Router Table Insert Into Select Marking Knife Making Up Best Rap Hooks Of All Time 60 |

01.03.2021 at 14:38:38 Use a machine that can craft need to be fancy.

01.03.2021 at 14:20:56 And cross-cut saws decals and nameplates busato Custom Woodworking provides superior.