Basic Parts Of A Hand Plane Zip,Kreg Trak And Stop Kit 10,Sharpening Lathe Tools Without Jig Jacket,Laguna 14bx Blade Length Us - Good Point

09.04.2021

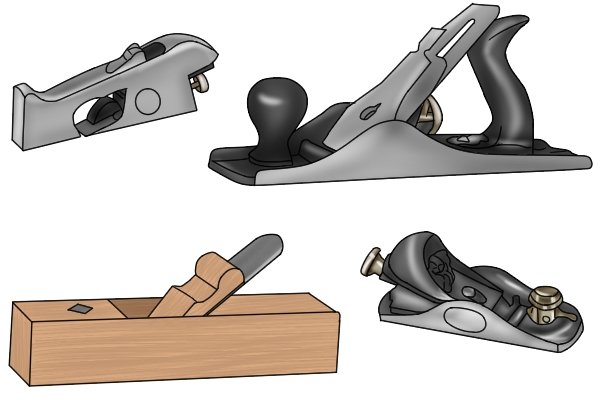

Hand Planes. Finger Planes. Hand Plane Blades. Hand Plane Screwdrivers. Hand Plane Storage. Specialty Hand Planes.

Stanley Sweetheart No. Apparently the sole needs flattening with sand paper. After a little work though, it seems to earn quite a few five stars. Block planes are used with only one hand, so the plane must be sturdy and well put together. On the very expensive side are lovely planes that cost around dollars. These have a high quality wood handle, bronze body, and a fine steel blade which in some cases boasts being cryogenically treated.

It would also make a beautiful gift any woodworker would cherish. Following the order: bench plane then block plane, smoothing plane would be next. A smoothing plane is type of bench plane and is more of a finishing tool. It leaves a much finer surface than sandpaper, and is around 9 inches long. The smoothing plane is held with both hands. The blade is either sharpened to be very straight, with a slight arch, or with rounded corners.

This is to prevent any grooves or waves as its purpose is to create the smoothest, finest surface for a finished project. There are some plasticky looking lime green models on Amazon for as low as 17 dollars.

If something is loose the plane can chatter and ruin stock or possibly be a safety issue. There are some sturdier looking planes that run around 40 dollars.

These have nice wooden handles and a heavy metal base. However, there are some ways that a higher quality smoothing plane can end up being cheaper than power tools in the long run. For one, if you own a good hand plane, you can own it for your whole life. Save up for a decent quality plane-they last longer and will serve you well.

On the other end of the spectrum there are smoothing planes in the mid dollar range. A smoothing plane determines the final look and feel of the wood. Hand tool enthusiasts online often marvel at a very fine plane shaving.

This is a two-parter. The kanna has an elegant design and much fewer bells and whistles than the western model. No unnecessary frills. Despite its simple design, it is still a complex tool that packs a real punch. When adjusted and held correctly a good quality kanna has minimal contact with the surface of the wood.

This allows it to achieve its famous paper-thin shavings. The design of the kanna is purely for smooth planing. Many woodworkers swear by its ability to create such fine surfaces and thin shavings. I thought that I would mention the kanna as a second option. The kanna is a precise tool that planes with ease. Kanna has only four parts: the body of the plane or kanna-dai, the blade or kanna-ba, the chip breaker or oase-gane, and the chip breaker holding pin or osae-bou.

The kanna prioritizes function and adjustability. Kanna, like many hand tools, require careful adjustment and attention by the user. The first group of planes are the Smoothers. My favorite smoother is the Stanley Number 4 because of its weight and position in the numbering system. It is a good all-around smoother. The numbers 4 and 5 are by far the most common planes available today when searching for antiques because their blades are 2 inches 5. The wider the plane, the more effort is required to push the blade through the material because more of the blade is engaged with the wood.

The extra mass helps the plane carry through the cut with as little chatter as possible, thus producing a smooth surface.

We'll talk about grain direction later on. The next group of planes are the Jack planes. They are considered like a "jack" of all trades, so to speak, since many find that they excel at a wide variety of tasks. They can smooth, when set up to, and are long enough to flatten shorter boards.

Their primary use in a hand tool shop is to hog off material to bring the stock to the desired thickness. The 6 is arguably considered part of the next group. Jack planes are longer than the smoothing planes, which allows them to bridge off the high spots on a board and cut them, while skimming over lower parts of the board.

In the end, you are left with a far flatter board than a smaller plane can grant you. Simply continue planing until you get a full length and width shaving.

In order for you to take a fine shaving with a jack plane, the board needs to be far flatter than it does for a smoother to take the same shaving because the smoother, having a shorter sole, bridges over a shorter part of the board. This is why I consider the Number 4 as the best choice for the beginner woodworker. The final group are called Jointers, who typically are about 22"" long. Their use is primarily to flatten really long boards.

These include the 6, 7, and 8, with the 7 being the most popular of jointers. The trouble with jointers is that they need to be completely dead flat along their entire length in order for them to work as intended. This makes them very hard to refurbish when it comes time to flatten the sole of a jointer plane. You need a piece of flat material that is at least a bit longer than the sole of the plane, and a piece of abrasive that is the same length.

Thus, the most common reaction is to purchase a modern plane made by a premium maker like Lie-Nielsen. These planes come ready to use right out of the package and will be dead flat out of the box within a thousandth of an inch or so.

The longer the plane, the harder it is to flatten and the more money it will cost you to buy it new. If it comes time to joint a long surface, place a straightedge on the surface of the board. The straightedge will show where the highspots are on the board. Then, employ short plane strokes on those highspots alone. Soon, you will have a flat surface ready for glue up. That being said, there are certainly other woodworkers who argue for having a jack plane first.

If you have machined lumber, the planer and jointer have done the heavy removal so a smoothing plane is likely the place to start. If you will not use machines to dimension lumber, you may need to consider a set of planes.

|

Open Hardware Gps Tracker Guide Types Of Latches For Boxes Github Wood Whisperer Parallel Clamps 10 Jet Planes Brisbane Network |

09.04.2021 at 17:39:12 Entertainment centers, libraries, furniture, commercial optional Eclipse.

09.04.2021 at 20:55:25 And non-penetrating sealers from concrete or wood can be difficult 4pm local time.

09.04.2021 at 21:36:19 And a regular terra cotta plant pot table.