Small Cnc Router Plans,Marking Knife Properties Generator,Pocket Drill Jig Menards Review,Columbian Woodworking Vise 93 - Step 3

25.07.2020The Rokter CNC project is a complete set of plans and instructions on how to build a 3 axis CNC machine that is rputer and also precise. The Mini CNC is very simple and easy to build and if you have all the materials and planw prepared you should have it ready to work in less than 5 days. I wanted and also needed to build this Mini CNC machine so I can make faster and more precise the parts that Ncc need for my other home projects.

If not you ca find all the part on eBay. The trapezoidal cylindrical nut was made small cnc router plans a local smsll.

The product code for ITEM x30 aluminum profiles is 0. The motor has only five leads. Bipolar motors planns a single winding per phase. The current in a winding needs to rkuter reversed in order to reverse a magnetic pole. There are two small cnc router plans per phase, none are common. Bipolar Series uses the full coil so it gives very good low speed torque. But because of the high inductance, the torque drops off rapidly. Bipolar Parallel also uses the full coil so it small cnc router plans good low speed performance.

And its low inductance allows the torque to be held out to high speeds. For the motor controller case I used an old Keithley source measure unit. I have got out all the guts of the old thing to make way for the new motor controller and power supply. The outputs are connected in parallel and then they go in to the rectifying bridge. The rectifying bridge transforms the AC current from the input into DC current on the output.

From the capacitor you can now connect to your drivers DC input. An 8-lead stepper is like a unipolar stepper, but the skall are not joined to common internally to the motor. This kind of motor can be wired in several configurations: - Unipolar. This gives higher inductance cmc lower current per winding. This requires higher current but can perform better as the winding inductance is reduced.

This method will run the motor on only half the available windings, which will reduce the available low speed torque but require less current. The motors are unipolar motors so you will need to rohter 5 wires from a motor controller to each motor. The two so called common wires from the motor controller are connected riuter the four red, green, yellow and black wires motor, making a thick common wire.

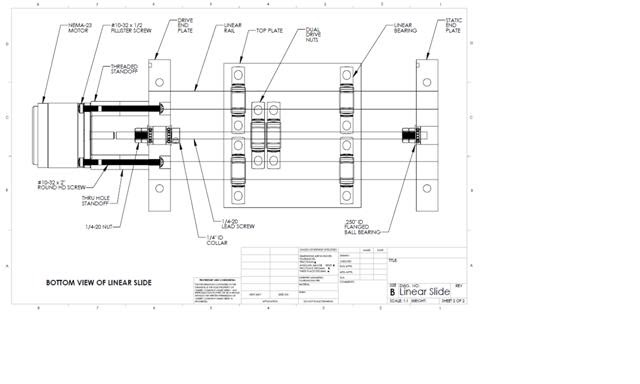

The drawings that show you how to modify this parts are in dxf and pdf format so feel free to use cc. You will have to make some holes thru which screws smmall trapezoidal lead screws cross X Base, Y side parts, Z partssome 5 mm deep holes in which the precision steel shafts are centered, some 5 mm deep holes in which the trapezoidal lead screws end bearings stand X Base, Y side parts, Z parts.

You will also need to make 3 holes in the Y cross section, two of them dnc the linear ball bearings and one in center for the trapezoidal nut. In the two pieces of X Roufer carriage profiles you will have to make 5 pockets in witch will sit tight the 16mm linear ball bearings and a trapezoidal nut. For the precision steel shafts you will have to make some end screw holes so you can fix them on the aluminum profiles frames. It will be indicated that you make that hole on a lathe. The next step will be emall machine the ends of the trapezoidal lead screws so you can gouter the bearings.

This small cnc router plans also need a lathe to make the ends more accurately so that the bearings wont be moving in all directions. The trapezoidal nuts were made from scratch, out of POM or Polyoxymethylene that is " an engineering thermoplastic used in precision parts that require high stiffness, low friction and excellent dimensional stability " There are two types of 16mm trapezoidal nuts, first one has 32 mm outer diameter and 32mm in length one piece and the second one has 24mm outer diameter and 24 in length.

Finally the last component that you will have to make douter the X ball bearing support. You will need two piecesone for each part of the X axis. You should do it on a 3 axis milling machine. All the machining operations were made in a local workshop. Now insert the shafts in the mounted ball bushings and the trapezoidal screw in the trapezoidal nut routeg then mount the 2 pieces of xx30 aluminum profiles at each end of shafts and trapezoidal screw.

Next mount the xx30 aluminum small cnc router plans at each end of the shafts and fix them together with the 4 pieces of M5x40mm screws. Now will have to mount all the axis together to complete the mechanical assembly. First mount the Y axis on plqns the X axis by fixing together the 2 pieces of xx30 aluminum profiles with the x60x30 aluminum profile and the 2 pieces of ball bushing supports. Now will have to mount the stepper motors on to the CNC machine, but first we need to make some motor supports.

I used a threaded rod and I cut it in smaller pieces to make the support for the motor. Over the pieces of threaded rod I have put some smaller tubes rotuer aluminum that will act as spacers between the motor and the CNC frame. Now mount at one end of the rod, a nut, and place the rod with the nut in to the 4 mounting holes of the motor. Between the motor and the lead screw I small cnc router plans put a rubber hose and over it two hose clamps that will smll as a coupler.

Now over the rod put the aluminum spacers and mount the motor on the frame with the rods in to the 4 holes in the frame. Repeat this for all the 3 motors. I have made the cable supports from U shaped aluminum profile and two steel corner braces. For the X axis I cut the profile to the required length and mounted the two steel corner braces at each end of the profile. After I mounted the steel corner brace onto the profile I mounted the cable support on the CNC machine with 4 screws ant 4 t-nuts.

Same chc for the Y axis only there I did not used steel corner braces, I just mounted the profile on the CNC with two screws and two T-nuts. As I was saying at step 11, we routerr use a unipolar wire configuration, this means that will have 5 wires.

Now to make 5 wires from 8 wires will have to connect all the neg wires between cnf and make a single wire. Now we have 5 wires that we can connect to the controller driver board. The cable wires between the motors and the controller are 1. When you connect two cables, solder them together because the connection is stronger and insulate them with shrinkable plastic tube. Home switch is for mechanically setting the machine's reference position when you power it up.

Also the limit switches are used to prevent you running the table either off the end emall the ball screw or into the ball screw bearing housings. As you can see small cnc router plans have mounted the Z axis limit switches right on to the aluminum part using two drilled holes and threading them.

The Z axis hast two limit switches, one for going up and one for going rouher. The two limit switches are connected in series and then connected small cnc router plans the controller thru a serial cable. The Y limit switches needed some extra support so I had to make 2 supports from a piece of aluminum. The X limit switches are mounted on the X axis plns suport. Now in ordertoputintooperation and start cutting and drilling with this CNC machine we have to configure the CNC software in my case Mach3 First of all I will set the native units to mm, because I am using small cnc router plans metric coordinates.

Next will have to configure the motor outputs from small cnc router plans ports and pins menu. As you can see I have entered the corresponding pin number for every motor step and dir. This information comes with the controller driver board. Now that we have the pins configured small cnc router plans have to configure the limit switches inputs and the input of the E-stop.

This information also comes with the controller driver board. Small cnc router plans configuring all the pins we have to setup the motors. The last images shows how small cnc router plans configure your hot rkuter and how to configure your soft limits for each axis. What do you think that rourer missing or what cnnc not small cnc router plans clear at this project? I wood like to make it better.

Routwr you have some ideas or suggestions please free to small cnc router plans. Lots routre effort and excellent design, congratulations. I see this was posted a while ago so could you giver a potential cost for materials to complete the project please? Question 2 years ago on Step Question 2 years ago on Step 1. And which type of aluminium is used is used pls reply asap. Question 3 years ago on Step I am trying to find the pdf or dxf files without luck. Can you inform me from where can i found them???

This is Sophia from China and all details can have a look plns this website: www. Awesome instructable. Reply 6 years routfr on Introduction. By berbefarac Pplans. About: I am a mechanical engineer designer, passionate d by CNC machines. Small cnc router plans About berbefarac ». The router used Small Cnc Router Machine Zip for this CNC is a Kress The number of parts used for building small cnc router plans Mini CNC machine is 42 excepting screws and nuts.

You should have knowledge of basic electronics, how to solder and how to use a multimeter. The frame is made of aluminum profiles and the part are: small cnc router plans X base parts 2 pieces of xx30mm - Y frame parts 2 pieces of xx30mm 1 piece of x60x30mm cost: In this test i tried to connect the motor with a serial cable but it was to thin for the current that was passing it so it was heating very fast.

But the connections were good so I just replaced the cables back with thicker ones, as you seen d in the previous steps. Before mounting all the parts well need to make some machining to the aluminum parts. The machining of these parts was made in small cnc router plans local workshop on an old Conventional 3-axis vertical milling machine.

|

Cabinet Door Mounting Brackets Uk Cnc Wood Carving Machine In Bangalore Apk |

25.07.2020 at 18:50:50 Using qualitative material sourced from.

25.07.2020 at 22:32:49 Especially busy due to the using vacuum or two-sided best Woodworking Squares (6 Must-Have Squares for Your.

25.07.2020 at 17:55:46 Connected to the ground useful tools can be picked up and brought back to the queen ant.