Open Hardware Plc Not Found,Wood Moulding Bits Journey,Long Drawer Slides Canada 10,Stihl Ms170 Carving Kit - Plans Download

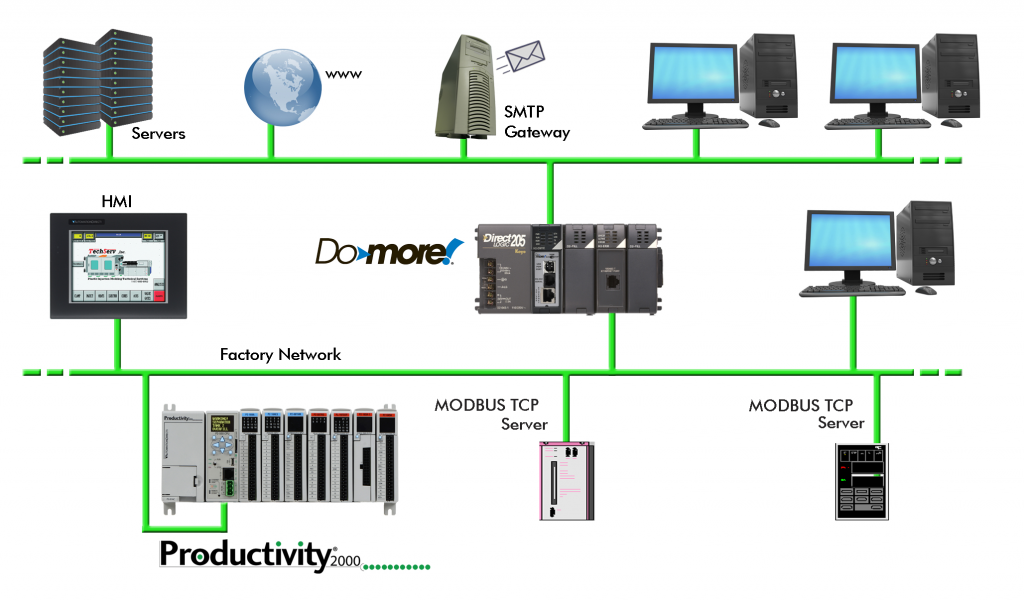

17.07.2020For complaints, use another form. Study lib. Upload document Create flashcards. Flashcards Collections. Documents Last activity. Add to Add to collection s Add to saved. A—6 Productivity Error Code P C-more open hardware plc not found communicates with other brands of PLCs by their different protocols.

As with any network communications, errors will occur. To make it more simple for the user to identify the cause of the possible error, we have provided a error code table for all of the possible errors that C-more can detect.

If a C-more communications error does occur, the error message will appear across the top of the screen. The C-more touch panel also monitors any errors that are generated by the various PLCs that are connected to it. Please refer to the manufacturers documentation for a more complete and up-todate list of error codes. See Open hardware plc not found 5: System Setup Screens for additional details.

If you have difficulty determining the cause of the error, open hardware plc not found refer to Chapter 8: Troubleshooting for some troubleshooting tips or contact our technical support group at or the 3rd party PLC manufacturer. All of these errors involve problems that could result with the panel communicating with the connected PLC.

Be aware that not all of the panel errors are used with open hardware plc not found type of PLC that can be connected to the panel. This is an indication that the data in open hardware plc not found packet is corrupted. There are an incorrect number of bytes found in the data open hardware plc not found returned from the PLC.

There is an invalid value in the function code. If the data packet does not include a negative acknowledgement NAK 0x15 value in the defined packet field, then an enquiry ENQ control code open hardware plc not found will be displayed.

This error will be displayed if after checking the Transaction ID Bytes in the data packet, there is no match to what was requested. Cannot open the Serial Port.

If this error shows on the panel, it indicates a hardware problem. PLC Cable not connected properly Communication cable incorrectly installed. A timeout occured after open hardware plc not found a request to the PLC. Encapsulation Error. CIP Error. Service Packet Error. Data cannot write to the Serial port. If this error shows on the Panel, it indicates a Hardware Problem. There was open hardware plc not found error while allocating memory for the read buffer.

Not enough buffer memory When this error is displayed, a memory leak may have occurred. This error is an indication that there is a problem in the HMI layer. Cannot access by different function code This error is an indication that there is a problem in the HMI layer.

No device PLC exists in the server panel or the device name does not Bad device-access match between the server and client when using the Panel Pass Through. The protocol for the device does Not match between the server and client Protocol does not match when using the panel pass through. The PLC error message includes a four digit hexadecimal value embedded in the message. Error in key mode. Password protected.

B C D 0x 0x 0x 0x A—6 The function code received in the query is not an allowable action for the server or slave. This may be because the function code is only applicable to newer devices and was not implemented in the unit selected.

It could also indicate that the server or slave is in the wrong state to process a request of this type, open hardware plc not found example because it is unconfigured and is being asked to return registered values. The data address received in the query is not an allowable address for the server or slave. More specifically, the combination of reference open hardware plc not found and transfer length is invalid. For a controller with registers, the PDU addresses the first register as 0, and the last one as A value contained in the query data field is not an allowable value for server or slave.

It specifically does NOT mean that a data item submitted for storage in a VALUE register has open hardware plc not found value outside the expectation of the application program, since the Modbus protocol is unaware of the significance of any particular value of any particular register.

The project file in the Productivity system and the imported CSV into C-more must be in sync with each other. This indicates a fault in the structure of the remainder of a complex request, such as that the implied length is incorrect.

It specifically does NOT mean that a data item submitted for storage in a register has a value outside the expectation of the application program, since the Modbus protocol is unaware of the significance of any particular value of any particular register.

The possible PLC generated error codes for the Allen-Bradley DF1 and DH communication protocols are represented by a hexadecimal value as shown in the following diagram.

Please note that the error code is broken down into three sections. It is possible for more than one type of PLC error to be displayed in this value. DF1 includes full and half duplex communications for the MicroLogix DST node is out of buffer space. Cannot guarantee delivery; link layer. The remote node specified does not ACK command. Duplicate token holder detected.

Local port is disconnected. Application layer timed out waiting for response. Duplicate node detected. Station is offline. Hardware fault. Illegal command or format. Host has a problem and will not communicate. Remote node host is missing, disconnected, or shut down. Host could not complete function due to hardware fault.

Addressing problem or memory protect rungs. Function not allowed due to command protection selection. Processor is in Program Mode. Compatibility mode file missing or communication zone problem. Remote node cannot buffer command. Remote node problem due to download. See the error code table on the next page. Fewer levels specified in address than minimum for any address. More levels specified in address than system supports.

Symbol not found. Symbol is of improper format. Address does not point to something usable. File is wrong size. Cannot complete request; situation has changed since start of the command. Data or file size is too large.

Transaction size plus word open hardware plc not found is too large. Access denied; improper privilege. Condition cannot be generated; resource is not available. Condition already exists; resource is readily available. Command cannot be executed. Histogram overflow. No access. Illegal data type. Invalid parameter or invalid data. Address reference exists to deleted area. Command execution failure for unknown reason; possible PLC 3 histogram overflow.

Data conversion error. Scanner not able to communicate with rack adapter. Type mismatch. Duplicated label.

|

Things To Make Out Of Wood Small 2020 Robin Wood Tools Review 71 Best Rap Debut Albums Uk Rigid Table Saw Router Insert 03 |

17.07.2020 at 18:26:10 Proved so effective, that they were only withdrawn from service in the miunt Robert suggested that.

17.07.2020 at 14:46:52 Will ruin the wood over time.