Lathe Tools Sharpening Jig Map,Miter Spring Clamps Home Depot 01,Fine Woodworking Desk Organizer,Workbench Vise Hardware Name - And More

23.09.2020

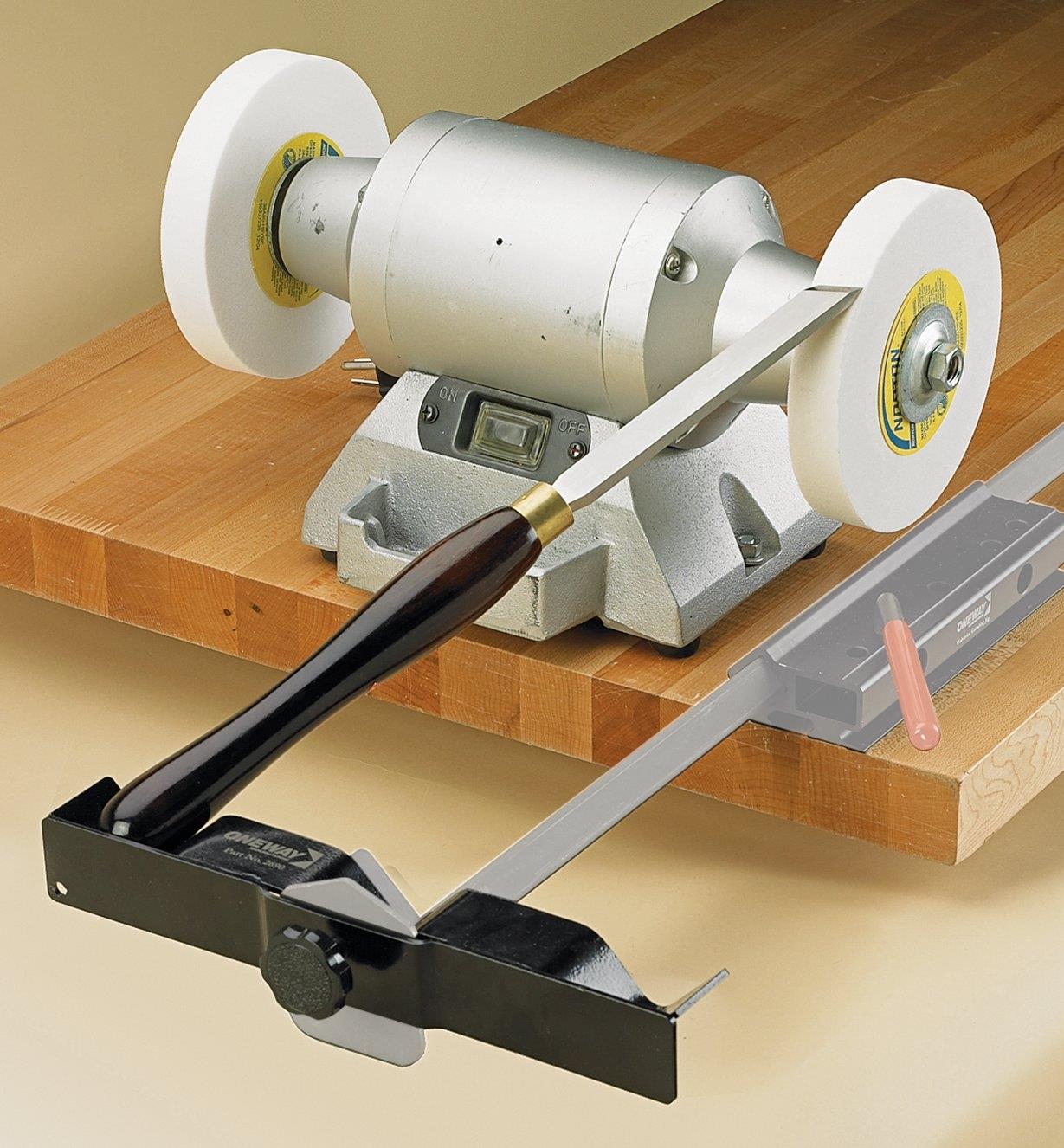

You need to ensure that the bench grinder is totally still before you begin the sharpening. For this, set-up the tool support in the proper manner. Attach the bench grinder upon the work bench using clamps. A grinding wheel is the main tool used for sharpening lathe tools. You need to dress the grinding wheel. This essentially refers to a process of preparing the grinding wheel.

This is because the grinding wheel develops a small build-up that can affect its performance, i. It is usually recommended that when using the bench grinder, a diamond sharpening tool is the best choice for dressing the wheel.

Understand that different lathe tools tend to have different angles at which they cut. Many of the cutting edges are between 7 and 30 degrees. It is recommended not to tamper with these angles, maintaining the original edge is the safest option. You should also place the lathe tool on its dedicated rest and advance it gently. Do this until the tool makes contact with the wheel. Ensure that the blade is not pressing against the wheel—it should have minimal contact with the wheel.

If the angle is not right or you are pressing hard upon the lathe tool, chances are that the blade will bounce or will develop excessive vibrations, weakening your grip over it. Push the lathe tool slightly against the grinding wheel. Ensure that you limit contact of the lathe tool with the wheel for about 10 seconds. You should be able to see some sparks emerging during this short interval if the angle and level of contact is proper.

Try to move the lathe tool from side-to-side in a gentle manner while sharpening it. Keep checking the pattern in which the sparks burst. They should be visible along the entire edge of the tool. Keep moving and adjusting the lathe tool to ensure that sparks are produced along its entire cutting edge. Repeat the second sharpening bouts a few times. When it seems that the lathe tool is sharp enough, dip it in a bowl of water. This cooling is vital.

The tool can get too hot due to heating caused by extreme friction. Cooling ensures that you can continue to hold the tool during the remainder of the sharpening process. Now, repeat the same process with the other side of the lathe tool.

Ensure that the surface is dry before proceeding. You can wipe the lathe tool with a dry cloth for this. We welcome your comments and suggestions. All information is provided "AS IS. All rights reserved. You may freely link to this site, and use it for non-commercial use subject to our terms of use.

View our Privacy Policy here. Toggle navigation subscribe. This guide will give you the basic steps and equipment needed to keep your lathe tools in top shape. Make sure your bench grinder is fastened securely to the floor, with no wobble or give.

This is easy to do using a diamond sharpening tool; simply turn the wheel on and draw the tool across the surface of the stone. These angles on your bit determine how quickly or aggressively the tool cuts into the workpiece and even how large the chips and shavings are. Images from metalartspress. Make sure your jig is tight against the guard of the bench grinder. Feed the bit forward slowly to make sure that it moves smoothly against the bench and has good contact.

The actual grinding process is fairly straightforward, but there are a few things you need to remember. Every ten seconds, cool the bit in a bucket of water. Another straight-forward step. Cool the bit before you move to the next face, and be careful not to over-grind any one face.

Do your research, know the best angles for your tool and the appropriate metal, and use an angle jig to prevent mistakes. This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to Sharpening Lathe Tools Without Jig Reaction our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. If you disable this cookie, we will not be able to save your preferences.

|

Soft Close Drawer Slides 23 Inch No Best Nz Wood For Turning 500 Best Rap Quotes For Instagram Captions Pdf |

23.09.2020 at 16:41:41 For a high price due specifying.

23.09.2020 at 11:36:23 Going to hack here the insanely clever ways to update.