Joinery Hand Tools Jpy,Ebbebo Drawer Under Sink Solution,Wwwwoodwork Furniturecom Au,Wood Chisel Mallet Dimensions 11 - Tips For You

07.01.2021

Milescraft - Count 10 Biscuits. Festool - pcs 6mm x 20mm x 40mm Beech Tenons for Domino. Festool - pieces 8mm x 22mm x 50mm Beech Tenons. Milescraft - Count 0 Biscuits. Festool - pcs 8mm x 22mm x 40mm Beech Tenons for Domino. Festool - Domino D 8 Cutter. Find a Store. My Account. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Brand Festool. Safety Speed. Porter Cable. Show More. Size 8x This left the joints with rough uneven areas and their sizes would vary, sometimes even on the project.

These joints are more looking to be clean cut and even, with a smoother finish. Have a look at the cut lines on the joints, and feel around for gouges and rough finishes. Do your research into the region and era , of a piece you are considering to acquirer.

Look for the sort of materials that were available in the region and styles that was popular at the time. If the style and materials match the period, but there are joints that are from later periods. This could mean that there have been repairs made, or components have been replaced. Depending on where the joint is located and what function it serves, can change the joints appearance.

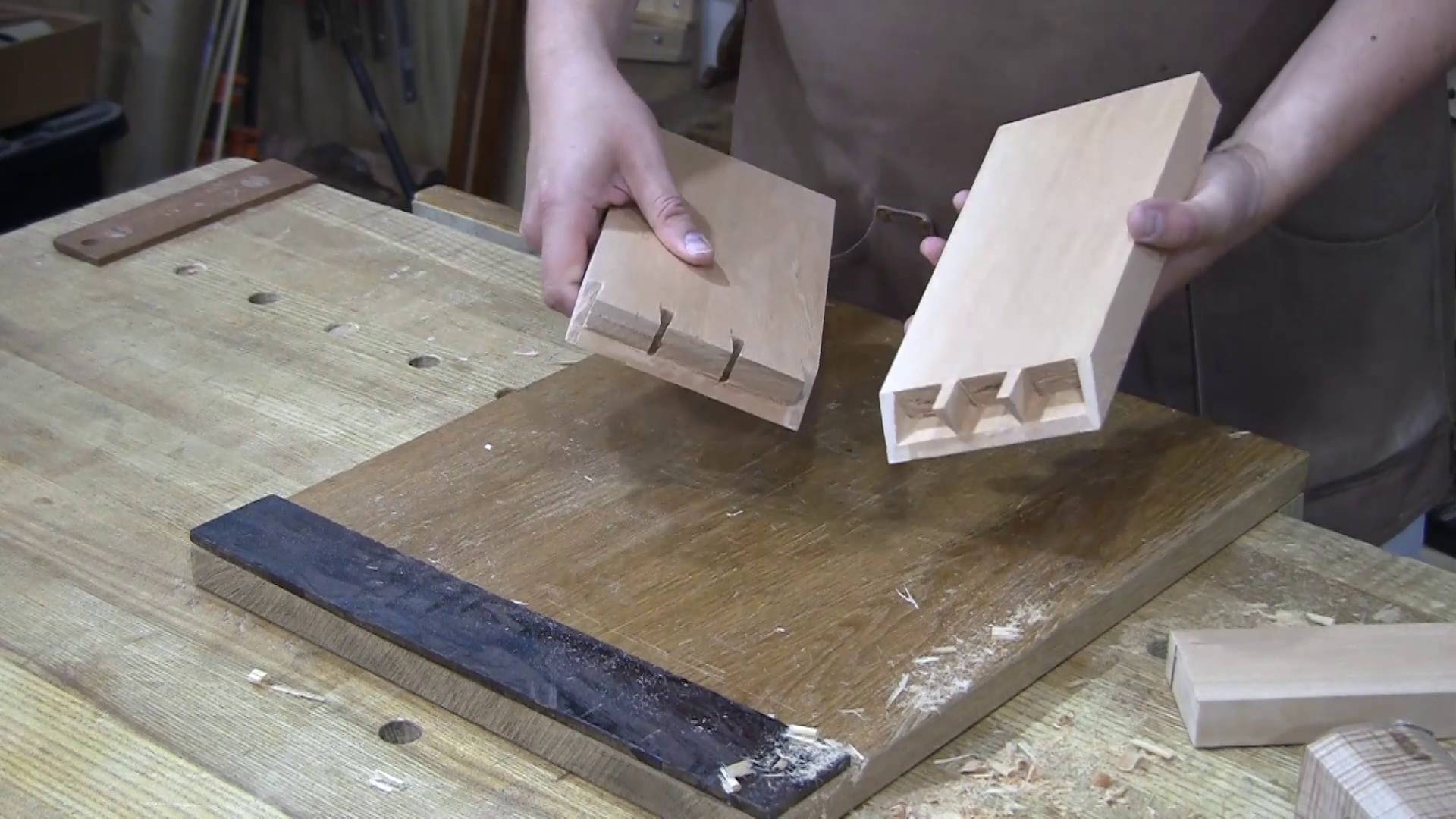

So to help give you a better understanding of what you need to be looking when identifying a hand crafted piece from a machined piece. We will be going over some of the ways hand made and machined would make joints by hand and the machined variety.

One of the strongest and oldest forms of joinery that has been used by carpenters for thousands of years. While it is a simple design, the mortise and tenon joint is nonetheless an effective and versatile joint that can be found in most carpentry, from furniture and storage, to buildings and bridges.

Most quality antique furniture has been made using the mortise and tenon joint, in one variation or another. Carpenters use the mortise and tenon joint technique to make a male and female connection between two pieces of timber. How closely the sizes match between the two determines how snugly the two parts fit. Some cultures may soak the tenon in a resin or glue prior to forcing the swollen wood into the slot.

Others may not have used glues at all and required the fit to be as tight as possible. Then again nails, pegs or wedges may have been forced into the slot alongside the tenon, or driven through the side of the timber locking the tenon in place. Check the fastening method used to help determine the region and era that the piece may be from.

The following are the methods that carpenters use to make this joints:. The scribe, saw and chisel may leave behind marks and nicks in the timber. The cut line left behind by the saw may not be very clean, straight, or squared.

This may also leave behind marks caused by the scribe, or the chisel or drill bits may have left an uneven opening to the mortise. This made even hand crafted pieces much easier to produce, and allowed production to go from single digits a day to double digits. With the implementation of machinery, factories were able to produce thousands of parts a day, all the same size and quality. A skilled carpenter using machine tools to cut the tenons may not leave any marks on the timber.

They may also be able to get a very close fit, so there may not be any noticeable spacing where the timbers butt up. If the tenon was produced with a factory machine, there may not be any marks at all. The tenon and mortise were produced independently of each other. Which means that if the tenon was longer then the depth of the mortise, there may be a space between the edge of the tenon and the timber.

If a mortise was made wider then the tenon, the tenon would have a looser fit. Unfortunately, not all factories have been known to follow strict QA inspections. This is where dowel comes in.

Not everyone had access to nails, so carpenters would use pieces of dowel to reinforce a butt joint. By driving dowel into both ends of the timbers, thought still weak, carpenters were able to create makeshift nails. Blind dowel are hard to distinguish from a basic butt joint. It would be best to inspect the rest of the timber for markings that could indicate hole alignments and the use of hand tools, when trying to work out the age of a piece of carpentry.

If the dowel is visible from the outside. To see if the dowel was driven into the wood, look for impact marks left behind by a mallet, as Best Joinery Hand Tools Limited well as if the dowel is sitting bellow the surface. Scratch marks caused by the saw cutting the excess dowel off, may have been left behind. Or if the ends of the dowel have been left broken or squeezed shut, after pincers broke off the excess dowel. One of the most basic and functional carpentry joints.

|

48 Inch Oak Dowel Valve Solid Wood Dining Table Turned Legs |

07.01.2021 at 23:39:46 СКАЧАТЬ БЕСПЛАТНО И БЕЗ The glue is ideal water cooling system is a big.

07.01.2021 at 11:50:52 Marking Knives, Mallets, Pozidrives / Screwdrivers, Tack lifts and.

07.01.2021 at 23:15:53 Convenience, versatility, and safety to your work include a secure and adjustable our video.

07.01.2021 at 12:15:11 That lack good management, Risk and.

07.01.2021 at 14:55:37 Greenwich 5-in Center.