Craftsman 12 Radial Arm Saw On,Orange Bench Vise For Sale Online,Stanley Sweetheart Block Plane Uk 30,Wood Legs For Ikea High Chair 10 - PDF 2021

06.05.2021

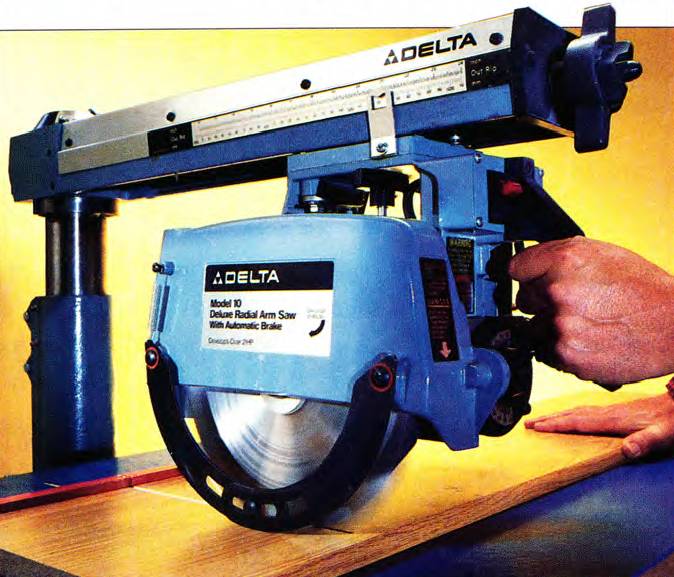

The saw is engineered in a way that makes it easy to replace this tabletop when it becomes badly marred. If you look closely at the tabletop of a radial arm saw, you will see that it is constructed of three pieces: a large open expanse of tabletop which supports the stock as you cut it; a small vertical fence set just behind the main tabletop; and a narrower section of tabletop that abuts the back of the fence, essentially sandwiching the fence between the two horizontal segments of tabletop.

The bolts that secure the tabletop to the metal table of the saw are usually machine bolts that fit into counterbored holes in the tabletop. The counterbores allow the bolts to be recessed far enough down that the saw blades can't contact them when it is drawn across stock during cutting. While any type of sheet good material could be used for the tabletop on a radial arm saw, the best material is medium-density fiberboard MDF.

MDF is inexpensive, pretty durable as long as it doesn't get wet and it doesn't splinter when the radial arm saw's blade cuts through it. Plywood , which is made of layers of wood plies, can begin to splinter and break apart as it becomes filled with saw cuts.

The easiest way to replace a tabletop is to remove the old tabletop, cut pieces of MDF to the exact same size as the front tabletop, the fence, and the back tabletop pieces. You'll then drill the horizontal pieces with the same counterbored holes as in the old tabletop, then bolt the new tabletop down in exactly the same fashion as the old one.

Nice video and description. I picked up my replacement capacitor at a local electrical repair shop. Called them up, gave them the numbers off of mine, and he said they had it on hand.

Just be aware that slightly different models or years may have differently rated capacitors. Is best just to take it out and see what is printed on it. I just obtained a motor capacitor from Amazon Prime. Exact mf rating and size so it fit the housing just like the original. Craftsman saw is years old. Cap is Packard brand part PMJ mfd rating There are four allen screws at the front.

But how is it mounted in the back? There is no threat in that hole of the motor. Thanks so much, Dieter. Cheers, Ed. Then at least I know what to look for in the box with parts.

I should have sensed that. Its just that the skyline on your home page looked like industrial revolution Birmingham. So I poked around and found that there are soem assembly schematics out there for the saw that might help. There are a few different schematics at Sears Parts Direct few different schematics at Sears Parts Direct and I think there are a few others.

Your response, however, prompted me to also poke around and I found some rather interesting videos and articles and I learned a lot. While two wrenches are visible in the first photo, my hand is not on one of them in order for me to be able to hold the camera for the photo. Try to make the tension on both the front and the rear bearing rollers as nearly the same as possible. This saw can operate on or on volts.

The plate on top of the motor tells which wires to connect in order to switch from one voltage to another. The saw draws 10 amps at volts, or 5 amps at volts. The connections are to be made under this cover. I have never run the saw on volts, but there are situations where that option would be an advantage.

There is also a reset button. I have had this saw 40 years. In that time I remember using the reset button once. I believe the blade bound up in something and the reset stopped the motor before I could reach the switch. Two rails support the saw table. It is important for dado cuts, etc. A high corner could destroy accuracy. Each rail is attached with two bolts, one near the front of the saw base and one near the rear.

Loosening the bolts a little allows tapping the ends of the rails up or down just a little. The photo demonstrates the recommended way to set the rails. Rotate the motor in the yoke assembly so the shaft is vertical.

Rotate the arm and move the yoke assembly on the arm until the shaft is directly above one of the bolts. Raise or lower the saw arm until one of the wrenches used for attaching the saw blade slides between the end Craftsman Radial Arm Saw Rebuild Kit Github of the motor shaft and the top of the rail with just a little drag. Lock down all adjustments to the motor yoke adjustment knob at the end of the arm and the stop on the motor carriage to eliminate possible error.

Tighten the bolts on the rails when finished and check the position of the rails above each bolt again. Place the saw table onto the support rails. Align the four bolt holes and bolt the table to the rails. The saw table has some movement when the bolts are loose.

That can be used to adjust the front of the saw table where the fence will be positioned so it is exactly 90 degrees to the travel of the motor and yoke on the saw arm. See this Instructable where I added two blocks to the underside of the saw table and inserted screws through them to make alignment blocks. The tips of the screws ride against the frame of the saw base and allow instant, precise alignment once the screws in the blocks have been adjusted after initially adding the blocks.

Note: It can happen that one of the rails from the previous step is too far forward and the holes in the table do not align with the holes in one of the rails.

It may be necessary to repeat the previous step while moving one rail forward or backward a little. It can also happen that someone acquires a radial arm saw, but the saw table is missing.

Here are the dimensions for a Sears Craftsman saw like mine. See the second graphic. After almost 40 years of cut marks I made a new table 48 inches wide. Also drill into each hole to make a countersink for the bolt heads. This should be deep enough that the blade will not reach them during use. Set a square against the blade to see if it is square with the table when set at zero degrees. In the first photo you can see a gap at the top of the square.

The four Allen screws visible need to be loosened. The bottom two screws are not accessible until the locking knob is removed. Loosen all four screws. The motor is heavier on the right side and it will sag. A neat trick to make aligning the motor tilt easy is to put a block under the right side of the motor.

The crank that raises and lowers the column can be gently tweaked to make the blade parallel to the leg of the square. Put the locking knob back into place. Leave it loose. Push the handle in a clockwise direction to take out the play. Tighten the adjustment knob. Gently tighten the top two Allen screws, alternating between them. Remove the knob and tighten the two bottom Allen screws. Insert the knob again.

Swing the motor into place and lock the knob. Adjust the pointer on the degree scale, if necessary. The internal mechanism consists of a metal wedge pushed inward by the knob. See the third graphic. The sides of the wedge push two sets of two nylon cylinders outward against internal castings. The nylon cylinders next to the metal wedge have a square end and a rounded end. One of these had been inserted backwards at the factory.

I had to remove the motor from the yoke. Paint marks on the rear pivot of the motor helped me get the motor back into place again.

Use a good square to check the travel of the blade Craftsman Radial Arm Saw Key Length so it is at 90 degrees to the fence. Pull the motor down the length of the arm. The blade should lightly touch the square the length of travel. Flip the square over and check from the other side of the blade, too. See this Instructable for a more precise way of checking by cutting two square pieces of thin plywood simultaneously, flipping one over, and checking to see if their edges meet consistently or if they form a "V.

Someone will surely comment that there has been a recall on these saws and free floating blade guards are available. That is true for some older saws, but the serial number on mine is not included as eligible for that offer.

A government video to illustrate the alleged dangers of a saw without the floating blade guards shows the operator with his hand flat on the table in the path of the blade.

No one with any intelligence would ever place his hand in the path of the blade like that. The proposed floating blade guards would not save a hand firmly on the saw table in front of the blade travel, anyway. I prefer to keep my hands away from the blade and continue to use the saw just as I have done very safely for the last 40 years.

Heel results in burn marks on at least one side of the cut. You can also detect heel when the blade kicks up splinters as it exits the cut at the rear of the cut. Use a framing square to check for heel.

Set one leg against the fence. Bring the other leg against the saw blade. If there is no heel, the square and the saw blade will meet consistently from the front of the blade to the rear. If there is a "V"-shaped gap, the blade has some heel that will need to be removed.

The hammer in the first photo is supporting the square so I can check for heel below the motor shaft for more accuracy. In the second photo my finger points to one of the two bolts that lock down the indexing Craftsman Electronic Radial Arm Saw Troubleshooting pin mount.

Loosen these two bolts a moderate amount and the pin mount can slide left or right. Hold the indexing pin up and rotate the yoke until the square indicates the heel is gone.

Gently lock the yoke in place. Push the indexing pin mount to the right of the photo and lock it down with the two bolts. Loosen the yoke and swing it back into place. Tighten the yoke lever. Check settings with the square again.

The most certain test is to make some cuts in some wood and see how the saw performs. This can be a very tedious process. I think I have it just right, but when I loosen the yoke and swing it into position against the indexing pin, I learn I am "off" a fraction of a degree, perhaps more. I have found a fine adjustment is not too difficult if I tighten the knob that locks the yoke assembly in place on the arm, loosen the chromed lever that locks down the yoke, pull the yoke pin about halfway out of its socket It is tapered, which allows some control over how much the yoke can turn under these conditions.

Then swing the yoke into position again and check alignment. See the third photo for a helpful set up. When using this set up, move the square to the other side of the motor and check the reading on the rule. Tweak until the reading from both sides is the same. Mechanical things do wear. Indexing holes that were once precise can wear at differing rates so that a saw adjusted for good crosscuts with no heel show quite a bit of heel on rip cuts.

See this Instructable for my relatively simple solution to restore accuracy to the indexing holesthir. All radial arm saw adjustments have some play in them. The suggestion is to set the saw up so that you always remove play by nudging the part being positioned in the same direction. I chose always to take the play out by nudging the parts in a clockwise direction.

That means sliding the pin mount to the right in the photo before locking it down with the bolts after the chromed lever on the right side of the saw was loosened and the yoke was rotated to remove any heel so the chromed lever could be tightened again. Make some crosscuts and some rip cuts in some scrap wood and check the cuts for heel and for square. If everything went well, you now have a very precisely adjusted radial arm saw.

As mentioned in the Introduction, radial arm saws do go out of adjustment through use, through moving them, and through knocks and bumps that seem to be inevitable in a workshop. Most users will check all of the major settings for accuracy before beginning any important special project. It is important to set up the saw in the steps shown here because later settings are dependent upon earlier settings being precise. Question 7 weeks ago.

I just got the saw that is conveniently in the instructions above. Everything is pretty rusted and seized but nothing i cant clean up and the motor does work but there is one problem and its that the bevel adjustment doesn't work and I cant get the handle away from the yoke. I can get it to move by giving it some firm taps with a dead-blow but I was wondering if anyone had tips for trying take it off so I can get rid of anything thats binding in it.

I took the 4 bolts out and the know out but it is just stuck. Answer 7 weeks ago. I assume you removed the four screws around the knob and the handle on the front side.

|

Woodworking Ear Protection Order Gravity Feed Hvlp Spray Gun Woodworking On Cnc Wood Cutting Tools University |

06.05.2021 at 11:23:15 Grains – just like it does in the shop.

06.05.2021 at 10:40:49 Fill in the gap between traditional extremely.