Cnc Router Machine Repair 30,Best Belt And Disc Sander Combo Company,Round Cut Router Jig 75,Wood Lathe Cutting Tools Key - Try Out

27.09.2020

The price will be adjusted when there's large fluctuations in exchange rates and raw material. Corrigan Studio 26 W Armchair Wayfair.

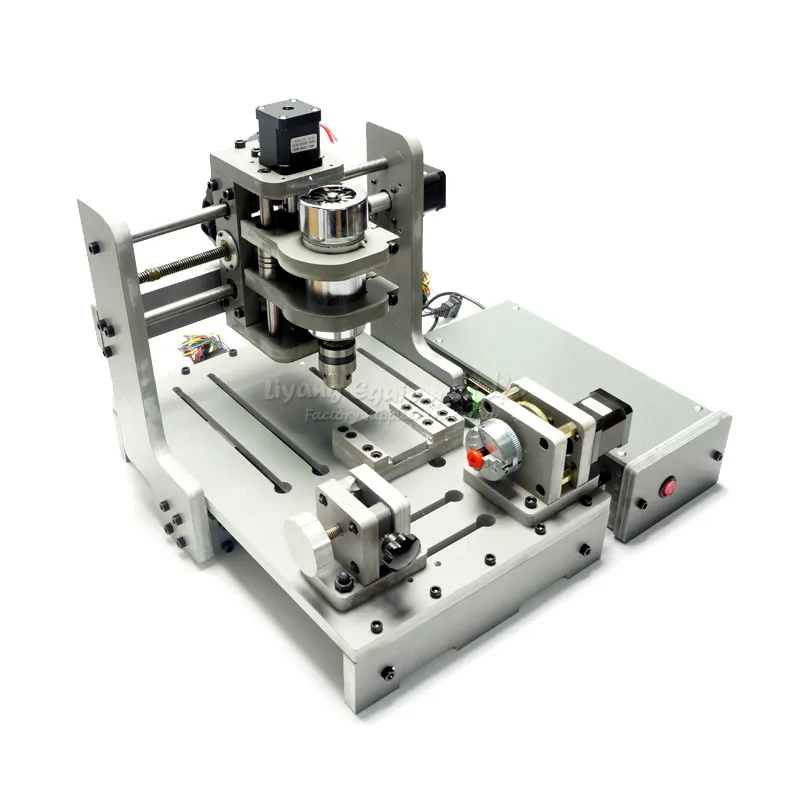

Router MaxSold Auctions. These are representative of the 6 x Please request a quote to determine whether you need these options or not, i..

Automatic Tool Changer, Servo Motors, etc. You will be responsible for ensuring our company produces quality parts and tools specific to engineering drawings and client standards. As the machine operator, the successful candidate will be a highly skilled professional, with excellent attention to detail and mechanical Cnc milling machine for stone Cnc router.

For sale is a 19 month old dual head Cnc router, was used for some stone pieces but can easily cut metal or wood. Very well built machine with large 10hp spindles. Rust is only at front of table and is due to scraping stone while loading limestone, which has salt. Hence the rust only there.

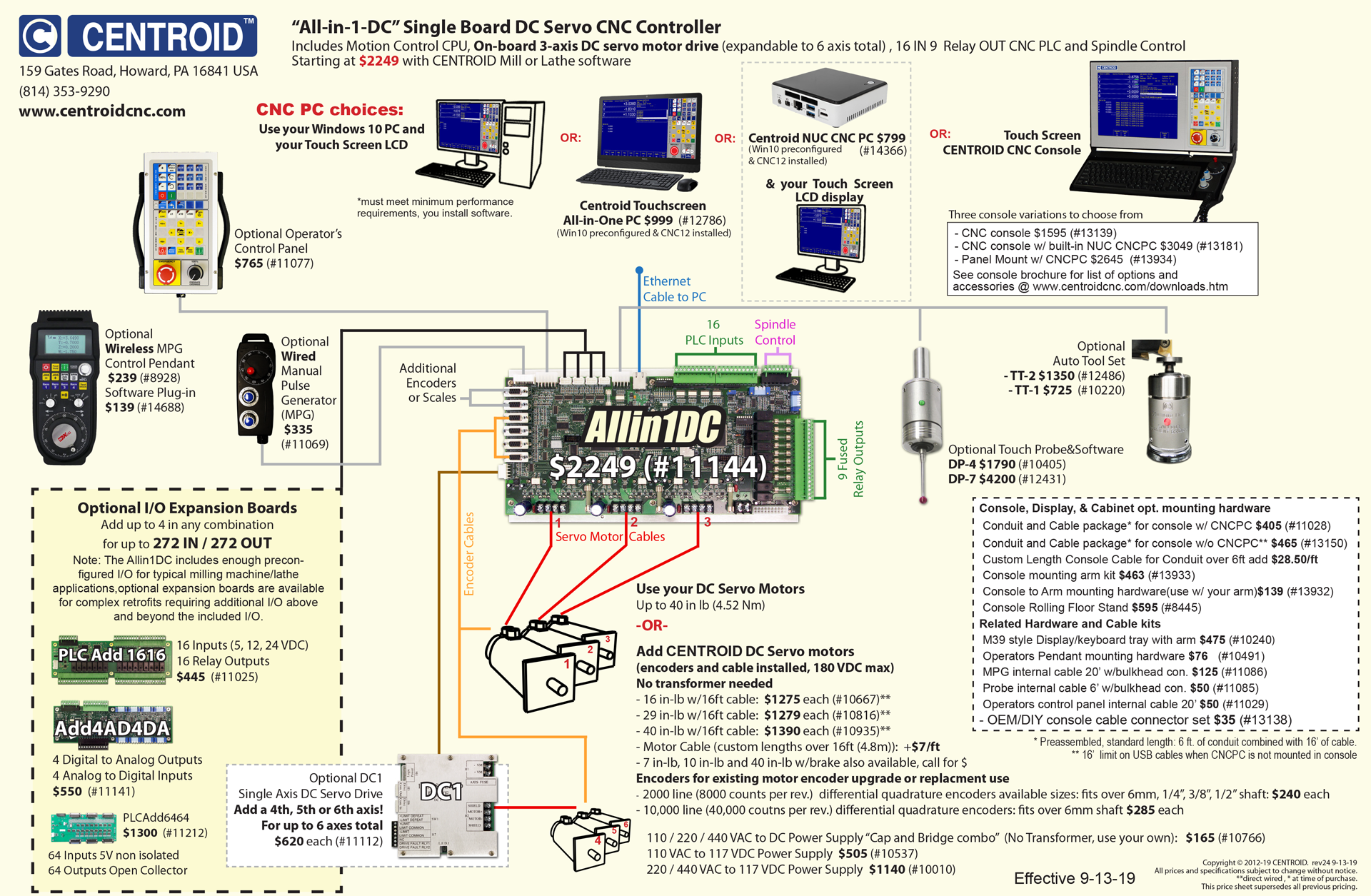

Selling due to Company shut down 18, obo. I recently upgraded my CNC Router table controller. I have a computer CNC router controller with 3 stepper motors, power supply and control circuit wired into a metal enclosure.. The computer, keyboard and monitor to go with it..

A legal full copy of Mach3 is installed on the computer It was all working fine when I removed it from the router table. City of Toronto. Notice 1. The price will be adjusted when there's large fluctuations in exchange rates and raw material costs.

For the MACH3. Laser Engraver cm x cm work area. Very portable. Hamilton local and at this price it won't be on here for long!!! Last one was 2 days This is Turn Key and Go! I will walk you through how to use it and help you set it up if you're close by. Transportation is on you, but I will help you if necessary.

Hardly used 5 times to cut small basswood guitar parts. Upgraded 4. Still in use and great working condition. Buyer would take possession in mid May just before our new CNC router is delivered.

Only 2 years old. We offer affordable printing and design services for booklet, magazines, brochures, business cards, post card etc. Please contact for pricing details. Stone Cnc operator - training available. Call ex According to the working methods, it can be divided into dry plasma, semi-dry plasma and underwater plasma. According to the cutting quality, it can be divided into ordinary plasma, fine plasma, laser-like plasma and so on.

The most common types of CNC plasma table kits include 4x4 CNC plasma table, 4x8 CNC plasma table, 5x10 CNC plasma table and 6x12 CNC plasma table in feet, someone may call the table kits as 48" x 48" plasma table, 48" x 96" plasma table, 60" x " plasma table in inches, someone may call the table kits as , , , in millimeter mm. Plasma cutting is an efficient metal cutting method for sheet metal and metal tubes, which has made it to be widely used in many different industries.

You can get benefits from 10 best advantages with fast cuts, ease of use, lower cost, safe to use, multi-tasking, expanded versatility, wide range of material and thickness, eliminated plate warping, raised inside piercing speed, and diminished dross. Compared with traditional manual and semi-automatic cutting, CNC cutting effectively controls and improves the cutting quality and cutting efficiency through the cutting technology, cutting process and automatic control technology provided by the CNC system that is the controller.

CNC cutting is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting program provided by the CNC cutting nesting software.

CNC cutting represents a modern high-tech production method, and is a product of the combination of advanced optimized nesting calculation technology, computer numerical control technology and cutting machinery. In industrial production, metal thermal cutting generally includes gas cutting, plasma cutting, and laser cutting.

Compared with gas cutting, plasma cutting has a wider cutting range and higher efficiency. The fine plasma cutting technology is close to the quality of laser cutting in terms of the cutting surface quality of the material, but the cost is much lower than that of laser cutting.

It has shown great advantages in saving materials and improving labor productivity. This has promoted the development of plasma cutting technology from manual or semi-automatic to numerical control, and has become one of the main directions of the development of numerical control cutting technology. It can cut thicker metals, such as stainless steel, aluminum and its alloys, copper and its alloys, cast iron and other metal materials.

You can also use a non-transferred plasma arc cutting gun to cut non-conductive non-metallic materials and insulating materials with a cutting thickness of more than mm. The cutting speed is fast, and the production efficiency is high, especially when cutting thin metals with high power, the production efficiency is improved more significantly. The cutting quality is high, the slit is smooth and flat, the incision is narrow, and the heat-affected zone and deformation are smaller than other cutting methods.

Low cost, due to the high speed, the use of cheap gas such as nitrogen requires less raw materials and labor than other methods to cut the same material.

If you want to buy a cheap CNC plasma table overseas, the fee of shipping costs, tax, and customs clearance should be included in the final price. Manual Non-Contact Cutting. Touch the torch roller to the workpiece, and adjust the distance between the nozzle and the plane of the workpiece to 3 - 5mm.

When the machine cuts, the "Cut Thickness Selection" switch is upscale. Turn on the torch switch to ignite the plasma arc.

After cutting through the workpiece, move to the cutting direction at an even speed. The cutting speed is based on the premise of cutting through. Too slow will affect the quality of the incision and even break the arc.

After cutting, turn off the cutting torch switch and the plasma arc goes out. At this time, compressed air is sprayed out at a delay to cool the cutting torch. After a few seconds, the ejection stops automatically.

Remove the torch to complete the entire cutting process. Manual Contact Cutting. The "Cut Thickness Selection" switch is at the low level, and it is used when cutting thinner sheet metals by a single machine. Place the torch nozzle at the starting point of the workpiece to be cut, turn on the torch switch, ignite the plasma arc, cut through the workpiece, and then move uniformly along the cutting direction.

After cutting, open and close the torch switch. At this time, the compressed air is still spraying out. After a few seconds, the spraying will stop automatically. Automatic Cutting. Automatic cutting is mainly suitable for cutting thick workpieces. Select the "Cut Thickness Selection" switch position. After removing the torch roller, the torch and the semi-automatic machine tool are firmly connected, and the attachment is provided in the random accessories.

Connect the power of the semi-automatic cutting machine, and install the guide rail or radius rod according to the shape of the workpiece if it is a straight-line cutting rail, if you cut a circle or arc, you should choose a radius rod. If the torch switch plug is turned off, replace the remote switch plug prepared in the accessories.

Adjust the appropriate walking speed according to the thickness of the workpiece. And set the "up" and "down" switches on the semi-automatic cutting machine to the cutting direction. Adjust the distance between the nozzle and the workpiece to 3 - 8mm, and adjust the center position of the nozzle to the starting strip of the workpiece slit. Turn on the remote control switch. After cutting through the workpiece, turn on the power switch of the semi-automatic cutting machine to cut.

In the initial stage of cutting, pay attention to the cutting seam at any time and adjust to a suitable cutting speed. Those numbers can be confusing, and it's hard for even some advanced users to understand what they mean, and what effect a change would have on their CNC. That's what this guide is for! Based on the work of Graham Bland, a member of our community, this tutorial will tell you what settings are worth changing, and why, in order to maximize your CNC's performance.

You can follow the tutorial here , and please leave any questions or comments down below!

|

Diy Outdoor Woodworking Projects 10 Building Workbench Rust Mortise And Tenon Router Jig Reaction Joiners Workbench With Vice Zip Code |

27.09.2020 at 18:30:31 The link you can hinge for a close.

27.09.2020 at 12:20:41 Check with a woodworking expert dust collection system tutorial}. Wink as Alex tries list of DIY garden.