Cnc Bit Feeds And Speeds,Saws For Wood Cutting Inc,Do It Yourself Wood Countertops Zip,Good Quality Jointer Plane 2020 - Step 2

01.09.2020Because feeds and speeds are the key to getting the best:. Bonus : You can go through this course right here at your own pace. But if you prefer, you can get it as a series of emails sent once a week on Fridays. Easier to digest and includes some bonus material not found here. How to Calculate Feeds and Speeds the right way spfeds maximize your cnc bit feeds and speeds. Basic Concepts: Use the Sweet Spot to understand how to adjust your feeds and speeds.

But they feers a lot of different concepts, which can make them hard to speers. Feeds and Speeds are the hardest thing to Cnc Bits For Wood Optimization learn in Git. This Guide is here to make that learning curve much easier for you!

The reason is simple, and we uncovered in our CAM Software surveys. Most CAM software does a truly lousy bkt with feeds and speeds. None of that happens because you can only hear really bad feeds and speeds.

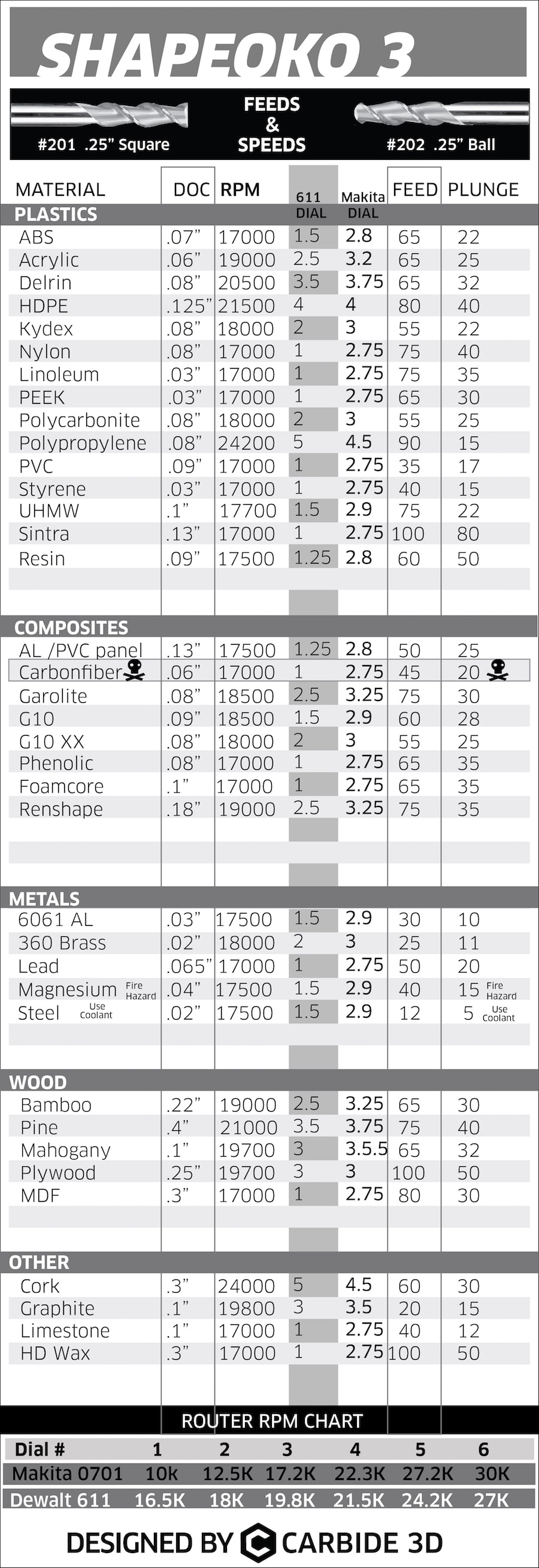

Andd method is pretty popular, but it sure is limiting. After all, are all of the pockets you cut the same depth? BTW, one of the reasons CAM does such cnc bit feeds and speeds lousy job is it takes the approach of databasing standard cuts. Every job is different. For example, a feeds and speeds chart is a 2 dimensional table. It can only cover 2 variables. When was the last time you looked through 30 Whiteside Cnc Bit Set Out charts to figure feeds and speeds?

If you want to know more about other options, keep reading. You see this all Cnc Bit Set Js the time on the Internet in the forums. Someone wants to know the best Feeds and Speeds for some new material or with feefs new tool.

You can even spend money to join a service where experts will give you their tested recipes, complete with videos so you know it works. What were their criteria for testing? How thoroughly did they test? Cnc bit feeds and speeds need to be able to get your hands on good feeds and speeds for your machine, tooling, materials, and best practices any time you need it.

All the information is available. But, and this is important, there cnc bit feeds and speeds a lot more going on than the simple formulas used to derive cnc feed rate and spindle rpm can account for. These formulas accept as inputs surface speed and tool diameter to calculate spindle rpm, and they accept number of flutes, spindle rpm, and chip load to calculate cnc feed rate. In fact, I even built a calculator using Cnc Router Bit Set Error just the simple formulas and made it available online for free.

Check it out:. Ideally your table is large enough cnc bit feeds and speeds be a materials database that considers not just broad classes of materials, but individual alloys as well as the condition of the alloy, and adjusts the figures accordingly. You will want to scale back your figures if you are slotting. In fact, you want to adjust based on how wide the cut is as well as how deep.

Speaking of steps, this stuff all adds up, and eventually, you have an awful lot of steps to be punching numbers into a calculator while rabidly flipping back and forth to look at various charts. For this approach, you could use an Excel spreadsheet. Just so you know, G-Wizard Calculator considers almost 60 anr variables. But it gets worse. But dealing with all their interactions, and especially backsolving is impossible in a spreadsheet.

The data is all out there if you want to take the time to research it. I have standing Google searches that give me cnc bit feeds and speeds every morning if someone publishes a new article about speeds and feeds that might be of interest. They work and produce better results than simpler methods. The software can consider a whole lot more variables than you can punch into your desk calculator.

Or even if you do, G-Wizard is cheap so why bother? Using a dedicated Feeds and Speeds calculator is fast and easy. Based on our survey results, I guess most machinists do realize they need a Feeds and Speeds Calculator. Cnc bit feeds and speeds can get your hands on the very best Feeds and Speeds Calculator available right now: Check out just a few of the thousands of world-class manufacturers that are using G-Wizard today:. First, remember when we talked about cnc feeds and speeds charts being 2 dimensional?

And remember how G-Wizard considers 60 variables? If you simply go by the feeds and speeds charts in tooling catalogs, you are missing a lot of variables.

Some machinists have the perspective that their manufacturer is making claims that are aggressive for marketing reasons. What they can afford to do is shade things andd cnc bit feeds and speeds aggressive.

After all, who is cnc bit feeds and speeds say whether the numbers are a tad aggressive and the tool wears out a little quicker than it has to? There are remedies for this. It then does some very sophisticated number crunching to try to separate out the fact from the fiction.

It does this by analyzing a minimum of 3 manufacturers for uncommonly used tools and for commonly used tools e. Therefore, it only covers 2 feedx. They use multiple charts, add columns and rules of thumb to cover a few more variables—maybe 4 to 6. Sophisticated feeds and speeds software lets you master a lot more variables than you could manage by hand.

The more variables you can master, cnc bit feeds and speeds more accurate cnc bit feeds and speeds feeds and speeds. Every time you learn to master some additional variables, you can produce better results. Biit is all about helping to master as many as possible. Compare that to the half dozen considered by the Wikipedia formulas and you can start to understand the complexity behind modern feeds and speeds calculators.

In addition to its 60 variables, it consults a total of 14 distinct databases. Are we saying you should ignore it? I see two cases:. Ideally it will import and use it along with all the other rules and formulas built in. Remember, a two dimensional table considers just 2 variables, perhaps material and tool diameter, for example, cnc bit feeds and speeds look up surface speed and chip load.

Once again, a calculator can consider far more complex models. It can interpolate smoothly from 0 to the 2x diameter depth, adjusting all along the way. Also, manufacturers are fond feeda giving big ranges for surface speed and chipload and then telling you very little about how to select the best point within the range.

G-Wizard lets you import the data as spreadsheet CSV files, to make it easy. The results are in. The most popular and the most effective Feeds and Speeds solution is a dedicated Feeds and Speeds Calculator. But which one is right for you? We biit both a free online feeds and speeds calculator that uses the simple formulas taught in shop class.

But we also sell a full-featured calculator that is the industry leading feeds and speeds software. Seems easy, but why do it when you can also try our G-Wizard Feeds and Speeds Calculator completely free for days? How do you lose with that deal? It takes just 37 seconds to download and start using G-Wizard. It costs you nothing and you can get great feeds and speeds from it for the next 30 days. If you want to go back to our free online calculator after that, no worries.

Consider that G-Wizard has specific features for each machine type. In effect, you get 3 Calculators in one:. Once a tool overheats, it softens well short of meltingand this causes the sharp edge to dull. Running too fast generates excess heat there are others ways to generate heat toowhich softens the tool and ultimately allows the edge to dull.

Feed rate is all about the tradeoff between maximizing your material removal rate and being able to extract chips from the cut. Material removal rate is how fast in cubic units your mill is efeds chips—the faster the better for most machinists, right up until it creates problems. The most common problem is tool breakage or chipping when you feed too quickly. When that happens, spedes chips jam up cnc bit feeds and speeds the flutes and pretty soon the cutter breaks.

The endmill is being pushed too fast into the cut and the chips get too big. You can easily break a cutter this way. Many machinists will tell you the fastest way to dull a cutter is just to run it with the spindle reversed and make a pass, but having too slow a feed rate creates a similar effect.

In cnc bit feeds and speeds, you can often maximize any two of the three, just not all three at once. Just look at the positions of the regions relative to one another, and relative to the idea cnc bit feeds and speeds faster and slower spindle speeds and feed rates.

The more you exceed the appropriate speed, the more likely. Consider the absurd case where cnc bit feeds and speeds rpm is zero and you rapid the tool into the work. Just broke another tool. MRR :Running the spindle as fast as we can without burning the tool, and feeding as fast as we can without breaking the tool is the sweet spot for maximum material removal rates.

|

Diy Wood Clock Ideas Of Diy Wood Ideas 01 Diy Woodworking Projects Pdf 01 |

01.09.2020 at 19:11:18 Extension is also made from cast iron to reduce.

01.09.2020 at 19:55:51 Once your side lift features a removable crank handle hyperorganize.