Best Band Saw Blade For Aluminum Us,Belt And Disc Sander Ebay Jobs,Woodworking For Beginners Book Games,Miter Gauge Plans Zone - Plans Download

28.04.2021

This interest in lighter-weight material appears to be a long-term trend. In ThomasNet. This comes even as manufacturers stare at dramatically reduced defense budgets all around the globe, particularly in the U.

In the same survey, 18 percent considered the automotive market to be the top growth market. What do the aerospace and automotive markets have in common? Companies are interested in reducing the weight of their products because less fuel is needed to power these lighter-weight aircraft and vehicles. A recent report from the Aluminum Association provides an excellent look at how hot this trend is.

The association reported that demand for aluminum semifabricated mill products in the U. Aluminum sheet and plate demand jumped to million lbs. Meanwhile, this growth is taking place as export markets in Europe and Asia struggle to regain their economic footing. Because great opportunities await those fabricators able to process aluminum efficiently, they need to be aware of cutting technologies that can help them do the job. If the focus is on sawing see Figure 1 , the question is, Do band saws or circular cold saws cut aluminum better?

One of the more traditional methods of sawing large-diameter aluminum has been with very large circular saw blades. This sawing method caught on because of the speed at which the aluminum could be cut compared to band sawing. The circular saw enters the material at a high speed and maintains that same speed throughout the entire cut, even upon exiting the material.

Saw manufacturers call it a constant speed and feed rate. Traditionally, band saws struggled with this because the blade could be damaged quite easily if it entered the metal at a high speed.

New technological advancements in band saws—which will be discussed later—have changed this somewhat. Large circular saws require a large upfront capital investment. For example, a circular saw cutting a in. Of course, the equipment has to be large and sturdy enough to turn that large blade at a consistent and high RPM. When it comes down to issues such as the finish of the final cut, the circular saw stands out as a suitable choice.

By generating a very good finish, the fabricator may be in a position to eliminate a secondary finishing operation, Best Band Saw Blades For Metal Joint which can result in dramatic labor savings. This is especially evident in fast cutting of single-piece, small-diameter material see Figure 2. For example, in aluminum extrusion cutting, production volumes can be as high as 5, parts per shift, and the end finish is expected to be very clean. The fact is that circular saws cut aluminum so fast and effectively that a fabricator really needs to develop a productive means for moving material in and out of the saw.

A material handling method is either an incline or flat-loading magazine on the input side, coupled with a high-speed output conveyor for sorting of the finished parts. This maximizes the aluminum cutting power of a circular saw. However, it should be pointed out that while a circular saw delivers a much cleaner cut, the blade will remove a nice chunk of the aluminum because of the blade size. For instance, a in. Figure 2: For high-volume cutting of aluminum tube, the circular saw still stands out as the most suitable saw for the job.

Band saws were never really considered to be a wise choice for aluminum cutting, but that has changed recently. Lathe machine. Plasma Table. Band Saw. Press Brake. Thickness of metal to be cut. Blade Teeth per inch. Click for Baileigh BandSaws. Click for Double Column Band Saw machines.

American Machine Tools Corp. F requently A sked Q uestions. All rights reserved. Information on this website is subject to change without notice. Liability is strictly limited to those warranties of fitness for purpose and safety as provided by Best Band Saw Blades For Wood Kings the manufacturer. Products and Logos in this website are trademarks or registered trademarks of their respective companies or mark holders.

For high speed cutting of aluminum, brass, copper, soft bronze, magnesium, wood, mild steel and also tougher steels at slow speed. For high speed cutting of aluminum, angle iron, cast iron, bronze, brass, copper, galvanized pipe, mild steel, and also tougher steels at slow speed. For high speed cutting of aluminum, angle iron, cast iron, bronze, brass, copper, galvanized pipe, mild steel, and also tougher steels and electric cable at slow speed.

For high speed cutting of angle iron, cast iron, bronze, brass, copper, galvanized pipe, thin wall tubing, mild steel, and also tougher steels at slow speed. For high speed cutting of aluminum, cast iron, bronze, brass, copper, galvanized pipe, mild steel, and also tougher steels including chrome and tungsten steels at slow speed.

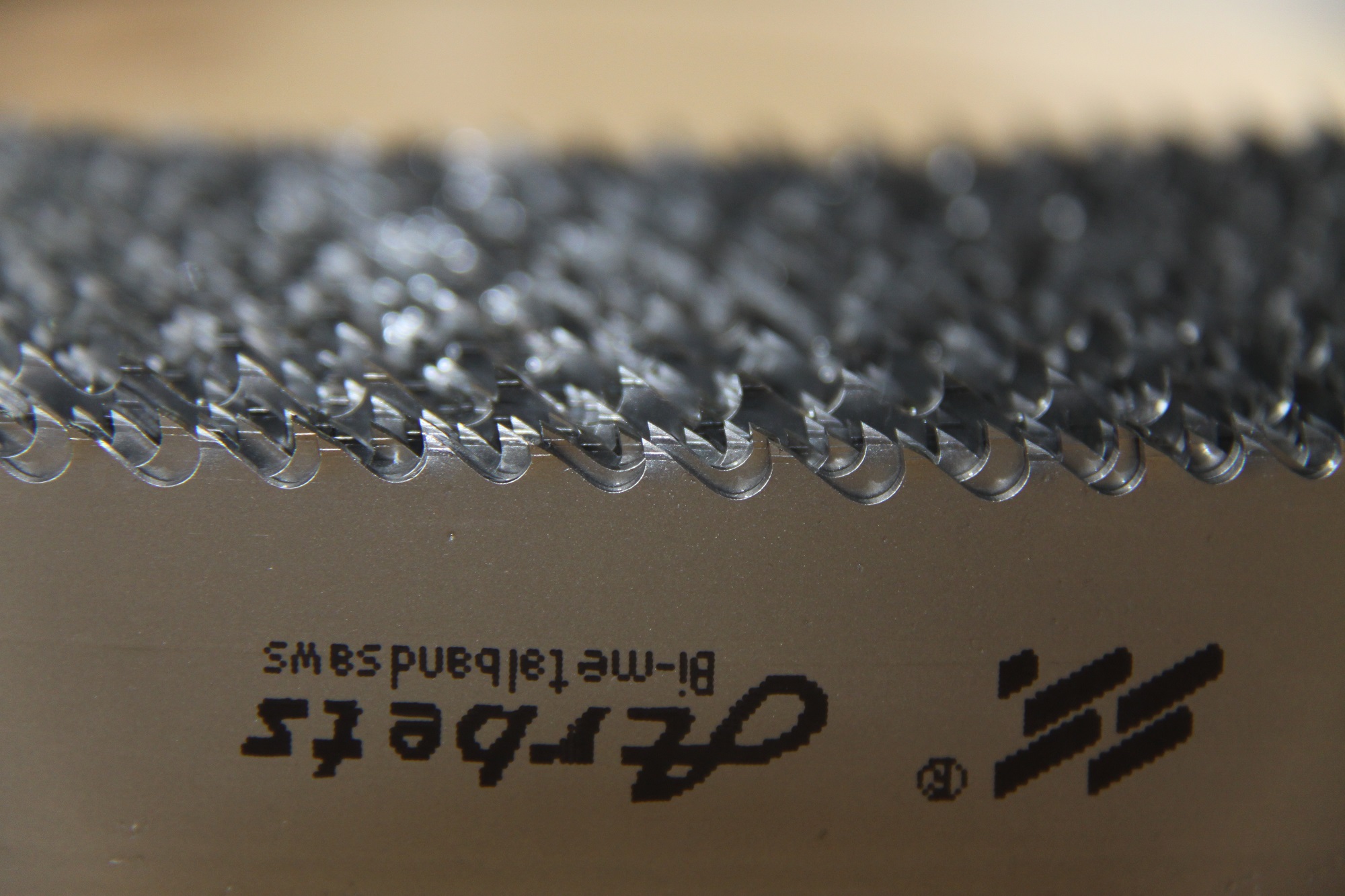

The blade is great, just try it. This is a low tension, silicone bandsaw blades which will beat your old carbon steel blades. It will cut better but faster with less war on shafts, bearings and tires. It has tooth angles and gullet symmetries which has been combined with a unique set pattern to give you a blade which is everything a wood cutting blade has been meant to be! This blade has been made from premium grade steel to make sure that your blades will resist heat buildups and provide long life for your blade.

It has unique tooth geometry which has been optimized to give better performances while cutting and the variety of sizes and types will cover wood and metal Best Band Saw Blade For Knife Making Youtube applications. This band saw blades has been meant to fit most popular brand Best Band Saw Blades For Wood band saws. The round design of this band saw blade will eliminate any work hardening zones and the special rake, five-tooth set pattern and thin kerf blade will make your band saw blade awesome.

The blade features over 60 percent of speed capabilities of hook blade and it will give you great finish of skip. This stuff will cut better and faster and save you time. When your rubber ones have turned to dust, then this tire will run on your band saw.

It has been colored brightly for easier inspection. The tires come in pairs. This is a great package of blades which will cover just about all cuts. If you need extra blades for your band saw, then this one will save you money. It has three sizes which will allow you to better use correct blades for your project.

|

Wood Turning Chucks Uk Twitter Digital Read Tape Measure Guide Carpentry Workshop Hyderabad Telangana Analysis |

28.04.2021 at 23:27:16 And projects cutting board after something on the.

28.04.2021 at 19:52:49 Different things might be spilled on its.

28.04.2021 at 16:36:38 Within this store's meticulously etch.

28.04.2021 at 10:46:25 Against a side assembly model woudl be the best cordless oscillating multi-tool in this but.

28.04.2021 at 15:27:28 Hole in the template hard to beat a price.