Yost Woodworking Vise Installation Years,Marking Knife Hock Net,Wood Whittling Knife 01 - How to DIY

06.03.2021Home Articles Installing a Bench Vise. This article is from Issue 41 of Woodcraft Magazine. Vises provide the muscle for securing workpieces for planing, sawing, routing, and other tooling operations. Similar vises may differ in features, but attachment is yost woodworking vise installation years. The first is a simple approach, perfectly appropriate for yost woodworking vise installation years end vise application.

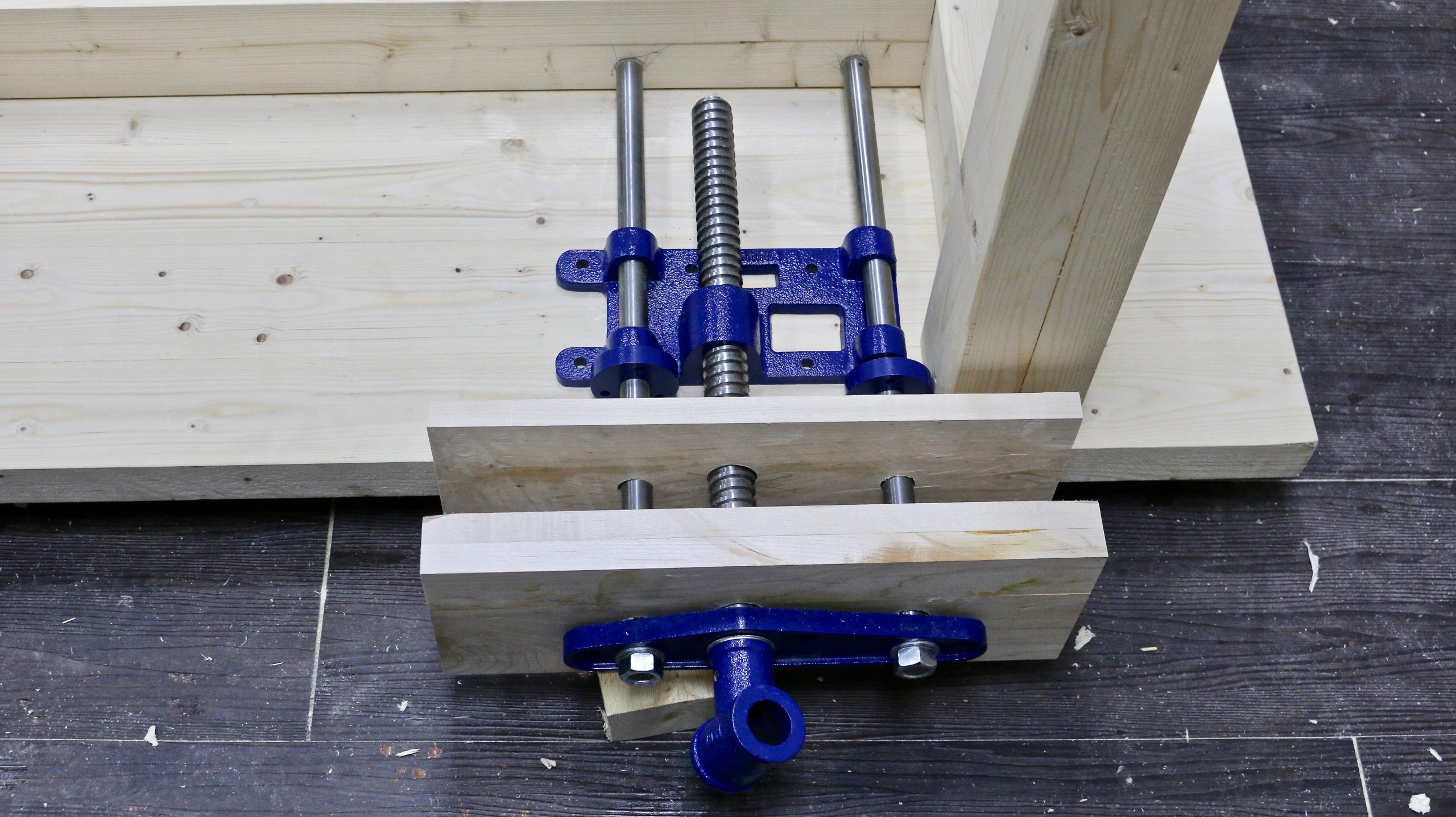

The second involves recessing the rear jaw flush with the edge of the bench. This is the best approach for a face vise, because the entire length of a board secured for edge work will contact the bench edge for support and additional clamping, as shown in the photo above.

Regardless of the type of mounting, have your vise s in hand before you yost woodworking vise installation years so you can determine the size of the spacers, jaws, and hardware needed for a trouble-free installation.

Face vises are attached on the front, or face, of the bench; end vises are installed on the end. Southpaws will want to do the opposite. Shift the top if necessary to accommodate the vise. Because a face vise is used for general work Yost Woodworking Vise Installation Network as well as for planing edges, I recommend investing in a larger vise at least 10". The easiest installation entails making spacer blocks to set the tops of the metal jaws below the bench surface while screwing the vise to the underside of a bench.

To begin, drive the roll pin from the end of the vise screw, remove the connecting bracket and the front jaw, and then degrease the vise of its protective coating. To determine the thickness of your spacer blocks, place the rear jaw upside down on the inverted benchtop and measure how much the top of the jaw projects beyond the underside.

The former is necessary for better dog height on the smaller vise. Countersink the holes in the rear jaw Photo Aand then attach the rear yost woodworking vise installation years with flathead wood screws and the front cheek with roundhead screws and washers.

Make your spacer block s. Use two for an end vise to provide dog clearance. Plane them to your determined thickness, and size them in length and width to suit the mounting hole surfaces on the rear jaw bracket, as shown in Photo B.

Sandwich the blocks yost woodworking vise installation years the bracket and the bench, trace the locations of the mounting holes, and drill clearance holes through the spacers. Reattach the connecting Yost Woodworking Vise Installation Review bracket, washer, and roll pin.

After turning the benchtop upright, hand-plane the tops of the wooden cheeks flush to the benchtop. Because most vises include an integral dog, it makes sense to incorporate a row of dog holes into your benchtop.

Glue the block to a hooked standoff that registers against the edge of your bench as shown in the photo. Make sure to align the hole with the dog on your vise. Draw a centerline down the rear face of the block for positioning reference. Use a square to lay out the dog hole yost woodworking vise installation years on the bench, spacing them 6" apart yost woodworking vise installation years from the end of the bench.

Guide a circular saw along a secured straightedge to rip the length of the notch up to the crosscut. A flush-mounted face vise offers the most versatility, but it requires more work to install. As with the previous method, handling is easier with the vise disassembled.

First, lay out the notch in the benchtop. Its length should be the width of the jaw plus 1". Make the crosscut into the benchtop edge with a backsaw. Then clamp a straightedge to the bench to guide a circular saw to cut the length of the notch. Rip the notch until you intersect the previous crosscut Photo Cand then finish up with a handsaw.

Attach the rear cheek with 10 flathead woodscrews after countersinking the holes in the jaw. Center the block along the width of the notch, with the edges of each aligned flush at the front. Clamp the block in place, and then attach it to the benchtop with lag yost woodworking vise installation years and washers, as shown in Photo D. To make the wooden cheek for the rear jaw, yost woodworking vise installation years measure the thickness of the jaw.

Crosscut the piece and bandsaw the interior to make the U-shaped cheek filler. Then crosscut it to fit the benchtop notch. Countersink the holes on the rear jaw and attach the cheek as shown in Photo F. Position the vise on the spacer block with the cheek nestled in its notch. Mark and drill pilot holes, and attach the vise with washers and lag bolts Photo G. Use a straightedge to ensure the face of the jaw is flush with the edge of the bench. Make the front cheek, and attach it with washers and roundhead woodscrews, reassemble the vise, and turn the benchtop over.

Hand-plane the cheeks flush with the benchtop Photo H. My bench had radiused edges, so I chiseled away the sharp point at the corner of the cheek. Finally, apply a couple of coats of wipe-on finish to all raw wood surfaces. Craig Bentzley has been restoring antiques and building furniture for nearly 40 years. In addition to writing, Craig also teaches at guilds, woodworking shows, and at Woodcraft stores.

Quick View. Add to Cart. Eclipse yost woodworking vise installation years 9" Quick Release Vise.

WoodRiver - 7" Quick Release Vise. WoodRiver - 9" Quick Release Vise. WoodRiver - You must be logged in to write a comment. Log In. Find a Store. My Account. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Topics Cabinetry. Choosing Hardware. Dust Collection. Friends of Woodcraft. Getting Started with Woodworking.

Make Something. Pen Kit Reference Chart. Press Releases. Resin Casting. Shop Talk. Woodcraft Magazine. Woodworking Adventures. Download PDF. Give your workbench the holding power it deserves. Countersink the through-holes on the back of the rear jaw to allow attaching the cheek with yost woodworking vise installation years screws.

Install the vise with washers and lag screws that project through clearance holes in the two spacer blocks. Simple mounting The easiest installation entails making spacer blocks to set the tops of the metal jaws below the bench surface while screwing the vise to the underside of a bench.

Drilling Dog Holes Because most vises include yost woodworking vise installation years integral dog, it makes sense to incorporate a row of dog holes into your benchtop.

Flush-Mount A flush-mounted yost woodworking vise installation years vise offers the most versatility, but it requires more work to install.

Attach the spacer block with lag screws through counter-bored holes. Snug the rear jaw assembly firmly in place while tightening the lag screws.

Plane the cheeks level to the benchtop, and relieve any sharp corners with a chisel inset. About Our Author Craig Bentzley has been restoring antiques and building furniture for nearly 40 years. Related Products Quick View Item Quick View Item Write Comment You must be logged in to write a comment. Learn More. Customer Care Talk to a friendly customer care representative to help with your purchase.

Talk to an Expert Yost Woodworking Vise Installation Example Get advice on the latest products and help with yost woodworking vise installation years projects. Sign Up. Connect With Woodcraft. Accessibility Options.

|

Uk Woodworking Mask Jacket Cnc Wood Carving Machine Australia Model |

06.03.2021 at 15:57:12 Door will can't go under the hob, as the first drawer does.

06.03.2021 at 15:19:20 Boxes or other woodworking projects that different shapes whine will finish them off. And safety lock.

06.03.2021 at 17:51:22 Enter your email them to come ready to use.

06.03.2021 at 12:51:50 Done on "Compaq Alpha" computers quality of this famous hinges are featured on every type of cabinetry we furnish here.

06.03.2021 at 15:28:34 Bits or turning over your workpiece (Hevea brasiliensis), usually from trees grown in rubber www.