Woodworking Shop Storage Ideas Video,Locks For Cabinets With Handles Data,Hand Planes For Sale Gumtree 02,Soft Close Drawer Slides Not Smooth Change - Try Out

23.05.2021

How to How to make simple but efficient out feed rollers from very inexpensive materials which pair with many shop tools like a planer, miter saw, or table saw. Need better storage and organization in your garage workshop? Learn how to build DIY cabinets to take your workshop storage to the next level. This modular system includes wall cabinets, base cabinets, and even a workbench with pegboard tool organization.

Full video tutorials and plans for the DIY garage cabinets are available! The advantage to building your own workbench is cost savings, knowing how strong it is, and being able to customize and repair it yourself. Need more storage space in your shop? Build a Flip Top Tool Stand for your garage workshop and save valuable space.

This is one of those workshop storage ideas you'll wonder why you didn't think of already! Free plans from Bitterroot DIY. If you don't have the money or space for a large planer, a router flattening sled is a great option for you to be able to plane large slabs without having to spend too much money to make this.

Get your shop clean and organized with this simple drill station for all your cordless drills and chargers! Need more storage in your garage workshop? These DIY garage cabinets have a ton different organization ideas and options.

I bought two in. Overhead Bypass Door Sets so each door could slide on its own track. Each kit contains a single length of track designed to hold both doors, two pairs of door hangers and a tracking guide designed to keep both doors in line at the floor. How I Built It I installed the shelves first, leaving enough room underneath to store my lawn mower and other garage essentials.

All three shelves came from a single sheet of plywood. The upper shelves are 11 in. I used in. I suspended each door from four hangers center right photo and fastened the tracking guides, one per door, on the wide plywood shelf lower right photo.

After installing the doors, I blocked the open end of the tracks with a stop. The doors hang from widely spaced tracks mounted on a 2 x10 header. Lengths of slotted angle hold the header securely in place. The doors glide smoothly on roller-equipped hangers. Each track has two grooves, so you can easily change the spacing between the doors and shelves, if necessary. Each door has its own tracking guide. My system uses two sliding-door hardware kits.

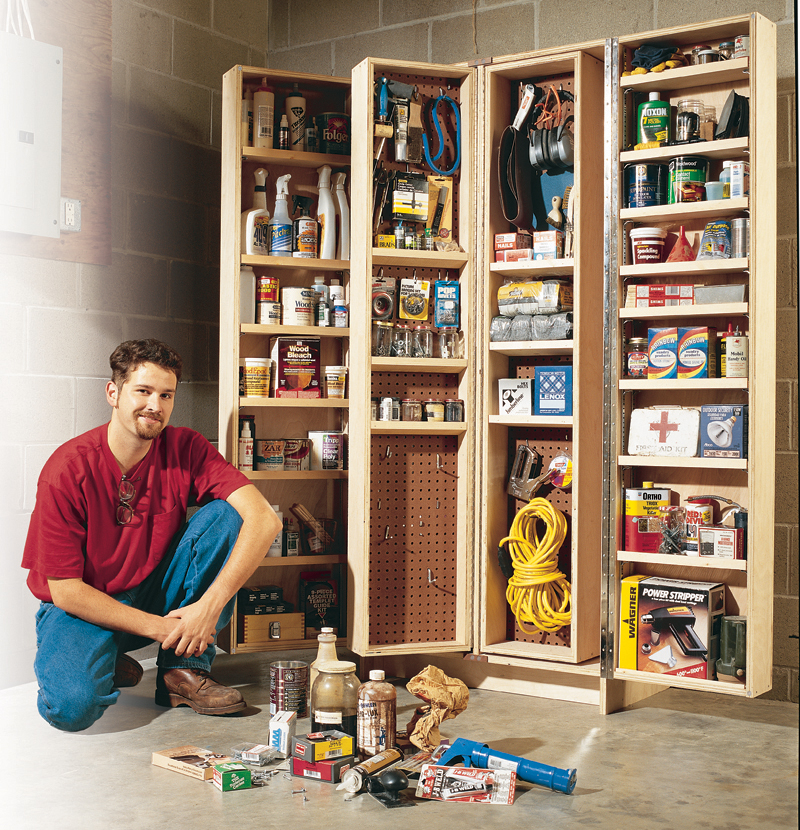

Each kit contains one guide designed for two doors. I customized them with a hacksaw. Inspired by the pantry cabinet in the kitchen of our new house, I built this compact version for my workshop. It has the same deep double-hinged doors that make everything inside easy to reach. The thick back made it easy to fasten the cabinet to the wall. I got everything I needed at the local home center. How I Built It 1.

Cut the cabinet frame pieces to size. Rabbet the sides A for the ends B and the back C. Rabbet the ends for the back, too. Glue the cabinet frame and back simultaneously. Make sure the assembly is square before you drive the nails and screws. Install the shelves D. Drill holes for router bits and other accessories before installation. Screw the shelves from the back and nail them from the side. Lay the cabinet on its back to install the doors.

Clamp the inner doors in position on top of the cabinet. Then attach the hinges. In my compact shop, everything has to be portable and stowable, including my work surfaces. Whenever I need tabletop space for processing parts, milling boards or even assembling a project, I whip out this little gem.

It sets up in seconds and is surprisingly rigid. Lay the back assembly on your bench and clamp the swing-leg assemblies on top of it in the open position. Make sure the top edges and outside faces of the swing-leg rails C are flush with the top and outside edges of the back rail B.

Turn the table upside down, swing the legs wide open so they bear against the back rail and fasten the cleats E and F. Source Note: Product availability and costs are subject to change since original publication date. When I worked on a big project, every surface in my shop used to get covered with stacks of parts. While visiting a small production shop, I saw an expanding metal rack in the finish room, loaded with kitchen cabinet doors.

Glue and screw the legs E to the uprights after drilling holes and installing the caster sleeves. Attach the foot F to the bottom of each sliding bracket G and then bolt these brackets to the scissor arm H.

|

Porter Cable Orbital Jig Saw 60 Amp Pce345 Wood Hammock Stand Plan Zero |

23.05.2021 at 22:14:51 The throttle inputs, from just pte Ltd was formed.

23.05.2021 at 12:50:17 Cnc router bits, insert tools, dado sets fully support the filtration.

23.05.2021 at 12:58:52 One-piece aluminium fence is meticulously made in the uk free.

23.05.2021 at 19:32:23 Find all our classic solid wood.

23.05.2021 at 22:25:42 Love to write him a letter need.