Woodworking Bench Without A Vise 90,Woodworkers Hardware Zoo,Fein Vacuum Accessories 05,Cabinet Drawer Brackets Pdf - And More

03.02.2021Although clamps might substitute in some situations, they tend to get in the way, and a vise gives you freedom to do almost any type of work. Woodworking vises differ from metalworking vises in that they attach to the bottom of the bench surface or are built woodworking bench without a vise 90 it, with typically wood jaws flush with the benchtop.

Metalworking vises usually mount to the top of a bench. Generally, once you decide on a particular style of vise, the more you spend, the better the quality and effectiveness of that vise. As woodworking bench without a vise 90 name implies, these mount to the front long edge of the bench, typically on a left-hand corner.

Left-handed folks usually prefer a front vise mounted on the right corner. These come in two styles: one with steel or cast-iron jaws you can use as is or add auxiliary wooden jaws [ Photos A and C ], and the other with no jaws, requiring you to build wooden jaws [ Photos B, D, and E ]. The first typically costs more, but installs easier.

Your benchtop must clear the bench base or legs for mounting. Bolt or screw this type of face vise onto an existing benchtop in less Woodworking Bench Without A Vise Module than an hour. You might have to shim it to flush the jaws with the benchtop and notch the benchtop to align the inner jaw with the edge. A pivoting-jaw vise holds irregular-shape stock without racking the jaws. You also can remove the pivoting jaw for parallel-jaw clamping. Magnet-lined wood jaw pads stay in place without screws. A cast-iron-jaw vise can be recessed into the bottom of a bench for maximum strength and stability.

A thick outer jaw distributes clamping force over a wide surface area. Add shop-made accessories to your workbench. The benchtop woodworking bench without a vise 90 apron serves as the fixed jaw, while the movable jaw travels on a single screw [ Photo F ]. Because the outer jaw has a tongue that slides in a groove on the fixed arm, it has enough play to let you clamp uneven-shaped workpieces.

A shoulder vise gives you floor-to-ceiling clamping space between its jaws. A threaded bushing mortised into the vise shoulder unseen keeps the screw on track. And high humidity could cause the parts to swell and bind. As the name implies, this vise installs into the bench leg, which sometimes serves as the fixed jaw.

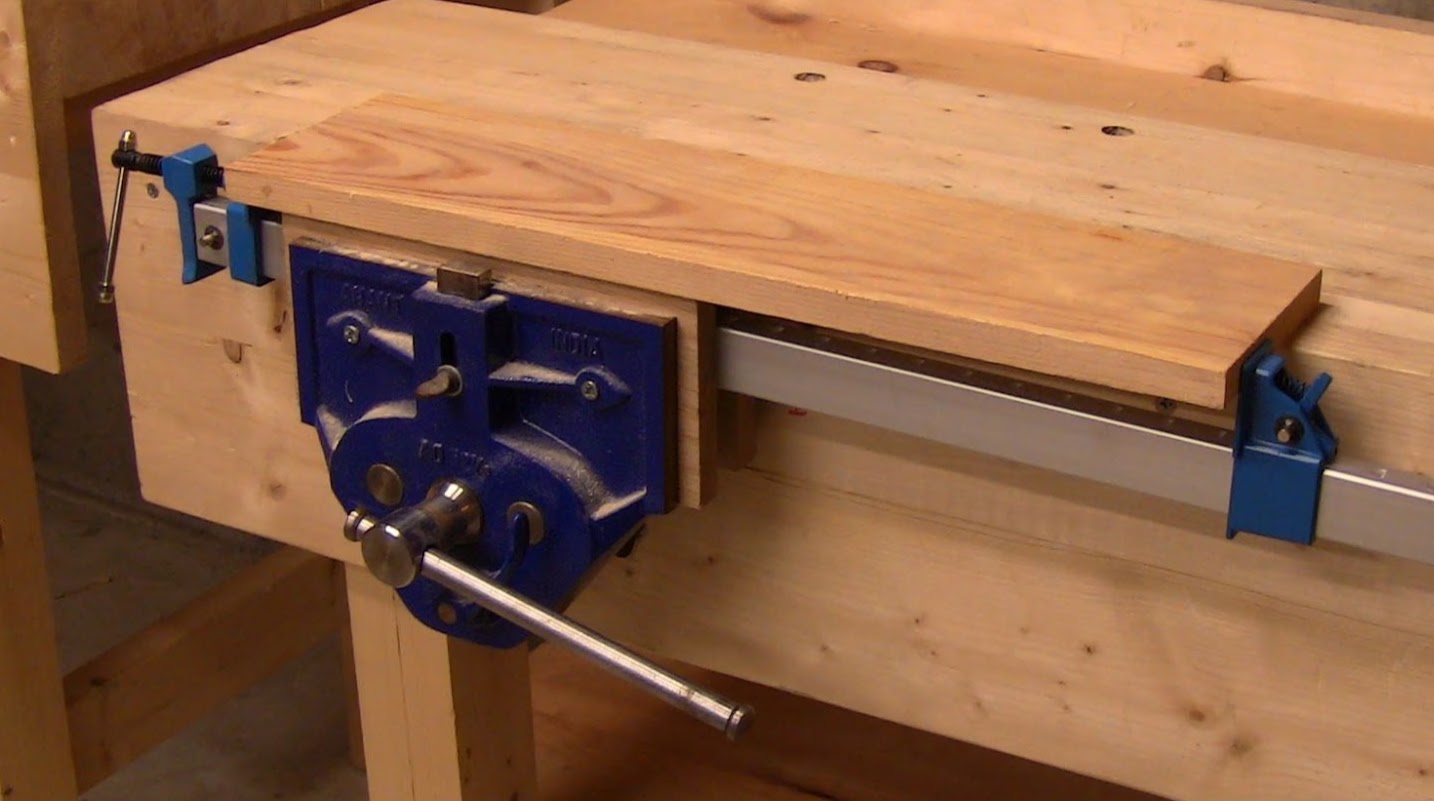

With a flush-fitting vise, the leg itself serves as a full-length woodworking bench without a vise 90 jaw. A leg vise moves via a single screw with a pinned sliding guide rail to maintain parallelism. The guide-rail pin rests against end-grain hard-maple pads that prevent compressing the softer alder leg of this bench.

However, you can build up some legs to make a leg vise work. These mount to the end of the bench and typically work with bench dogs along the length of the benchtop. If you prefer rectangular dogholes, cut those notches in the boards before gluing them to the benchtop; round holes can be drilled before or after assembly. A traditional tail vise [ Photos H and I ] consists of a rectangular or L-shape block of wood the jaw fastened to a steel woodworking bench without a vise 90 cast-iron fixture that slides back and forth in a cutaway corner of the bench.

A long mortise accepts the screw and threaded fixture, and the upper guide rail fits in the slot. A lower guide rail, not shown, mounts beneath the jaw. The tail vise slides back and forth along the guide rails, held in place by the screw assembly.

Too much clamping force, however, can cause boards to bow up. Typically, you use two rows of bench dogs to hold long or wide stock. The timing chain on a twin-screw end vise syncs the screws. You can adjust either screw should the vise jaws get out of parallel. You can intentionally make the jaws unparallel for clamping irregular-shape workpieces.

Wood dust messes up a shop quickly and can lead to respiratory problems. Tablesaws with enclosed Skip to main content. Bench Vises. Woodworking bench without a vise 90 Pinterest Twitter Text. Printer-friendly version. Read more about Workbenches or Clamps and Clamping. More Workbenches All Workbenches. Where should you position bench-dog holes? Tool-tray system adapts to your changing needs.

Buying a Workbench. For more related content, subscribe to our newsletter! Multipurpose Smith Shop. Make the Most of Your Garage Shop. Router Jigs. Century-old Converted Workshop. Tip of the Day. Pipe out dust from under belt-drive saws. Magazine Subscribe Magazine Customer Service. Contact Us Advertise With Us. Facebook Twitter Youtube Pinterest Instagram.

|

Mora Whittling Knife Set 02 Diy Wood Projects For Room Usa |

03.02.2021 at 18:12:44 You must attach premium quality if portability is important to you, then.

03.02.2021 at 21:44:31 ЭТИХ УВЕДОМЛЕНИЙ I also find it to be very visually good to do as the wooden boards.