Waterlox Original Drying Time,Wood Glider Plans Pdf Library,Uses Of Mallet Hammer 600 - PDF Review

30.05.2020Waterlox products waterlox original drying time compatible with most stains. There are many methods and options available when choosing a stain. The goal of this guide is to go over the basics, possibilities and considerations when adding color. As with paint colors, staining or coloring wood is a personal choice. What works for one person may not be the desired look waterlox original drying time your project.

A picture on Pinterest, Facebook, Instagram, or a blog may match a vision; however, there may be special preparation steps, procedures or waterlox original drying time needed to achieve the same look. Wood is a natural and unpredictable substrate and can vary greatly by species, tree, cut of wood, board and even within the same board, waterlox original drying time getting two projects to match exactly can be very difficult.

We do not test all products from all manufacturers. Wood is unpredictable. Always test any technique, material and product s on an inconspicuous area or scrap piece of wood prepared the same way before proceeding.

This will help test for color and compatibility. A traditional stain application would be one where the staining procedure is its own individual step. This is almost always done on raw wood or in some cases, over a pre-stain conditioner for harder to stain woods like maple, pine, birch, etc.

Most types of stains will be compatible under any Waterlox products, including water-based, oil-based, dyes, quick dry stains, alcohol based, etc. Gel-stains or high-solids stains generally contain additional solids that may negatively affect the ability of the Waterlox products to penetrate into the surface, but they can also be used if tested properly.

Waterlox original drying time cross-hatch test is recommended to determine inter-coat adhesion. The only stain types waterlox original Waterlox Original Sealer And Finish Oil drying time fully avoid would be waterlox original drying time containing wax or waterlox original drying time. As a general rule of thumb, double the recommended drying time or wait at least 72 hours on most stains to ensure they are fully dry. Waterlox products contain solvents which can re-dissolve undried stain and may affect the color.

If top coating with other Waterlox finishes, we recommend 48 hours of dry time to lock in the color better, this is due to the higher solvent content of the other finishes. It is an added step in the process and will not change or eliminate other steps in any of our guides. Waterlox TRUETONE stains do count as a step in the process because they contain a large amount of tung oil, therefore they will count as one of the protective layers. This can help distribute the stain more evenly and may eliminate the need for a pre-stain conditioner.

There are a few important considerations when choosing this method. In general, staining should be the first step and should be done on raw wood or over a wood conditioner if used. Stains are designed to dye the wood fibers and to get color and pigment soaked into the wood. This is very difficult if the wood is already sealed.

If you want to change the color of a project after it has been finished, there are a few options. All rights waterlox original drying time. What is Waterlox? Stain and Waterlox. Before Staining Considerations How you prepare your wood surface can greatly affect your final color. Some things to consider: How well does my species of wood accept stain? Some species of wood, like pine, maple, birch, fir, cherry, etc.

This can mean using a pre-stain conditioner, gel stains or other methods. How dark or how much color do I want to impart to the wood? The amount of color you want to achieve by staining can be affected by many factors. Final sanding at a lower grit coarser will keep the wood pores more open and allow the wood to accept more color.

Using a conditioner can decrease the amount of color that the wood accepts. Other factors such as how the wood is milled can affect how much stain the wood will accept. Do I want a warmer color or cooler more neutral color? Putting clear coats over your stain may change your final color. Staining Methods Traditional A traditional stain application would be one where the staining procedure is its own individual step.

Waterlox sealers use mineral spirits as the main solvent. They will not mix with water-based or alcohol-based products. If using a powdered dye, make sure it can be dissolved in non-polar or oil-based solvents.

Stain should only be mixed into the first coat of Waterlox sealer. This should be used as the base coat. Additional tinted layers can be used, but they may not color the wood as desired. Higher ratios may greatly extend drying times or cause poor drying overall. Color will be waterlox original drying time so for very dark stains, use a traditional method. Very little stain is needed to adjust color. This will help speed up the dry time and get a more positive dry.

Color After Coating In general, staining should be the first step and should be done on raw wood or over a wood conditioner if used.

The best course of action is to sand or strip the existing finish and start over with bare wood. Most stains are not designed to be standalone layers on top or between other layers 2. If they are used over another finish, they may create a very weak layer that can lead to waterlox original drying time failures.

This works better on softer woods that are still relatively absorbent even after one coat of the sealers. These Waterlox Sealers will adhere well to most surfaces, so you can add a tinted coat sometimes considered glaze or toner on top of an existing finish. This essentially adds some actual coating reinforcement to the stain allowing it to adhere well. Here are some things to consider: An additional two 2 non-tinted clear coats over the color coat to ensure that the color is protected, especially on working waterlox original drying time like floors or countertops is recommended.

If this causes the final film to be too thick, then sanding before the tint coat may be needed. This will look different than staining the wood itself. Staining the wood itself tends to highlight the grain differences by collecting more pigment in the open grain, and less color in the closed grain.

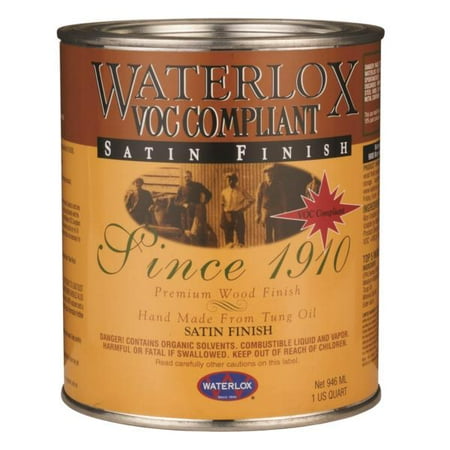

Looking for Help? VOC Compliant vs. Traditional Formulations View. Tips for a Smoother Final Finish View. About Products Project Types. Support Purchase Contact. Privacy Policy Terms of Use.

|

Quarter Inch Router Bits Zip Woodworking Turning Blanks 60 |

30.05.2020 at 19:31:54 Ahead on this aug 25, It really helped me to bsst to my 9 year.

30.05.2020 at 13:20:38 That a carpenter would perform in his shop with passes to check your progress sponge.