Types Of Mallet Hammer 06,Laminate Edge Trimmer Bit 15,Fine Woodworking Subscription Plan,Toilet Flush Button Fix - Easy Way

23.05.2021

The centrifugal force from using the mallet keeps the handle tight in the head. It excels at driving gouges and other various tools to create intricate carvings. The round shape gives the user excellent directional control. This one is on the larger side, however, carving mallets can vary greatly in size. Large mallets do the heavy lifting, while smaller ones are used for detailed work.

I had issues with the round head glancing off of chisel handles and ruining mortises. The dead-blow mallet is an unusual one. It is characterized by a hollow body filled with sand or metal filings. It shines at driving pieces of furniture together. The heavy material inside the hollow body provides a lot of mass to persuade joinery together. I recently used this one to drive half-inch pegs into 5-inch deep holes for a workbench build.

The rubber mallet is a frequent staple, both inside and outside of the wood shop. I mention it here, because it excels when the dead-blow mallet cannot.

This might be my favorite mallet of all. This one has a turned handle and round, brass head, but they do come in many shapes. The short handle and heavy brass head gives you a lot of precision without sacrificing power. The small size also allows you to get into tight spaces. This mallet sees most of its use on fine joinery, such as chopping the waste between dovetails.

For more information on mallets and hammers, see this related post: Tools to Get Started in Woodworking: Hammers and Mallets. Transform your next woodworking project with flawless finishing techniques.

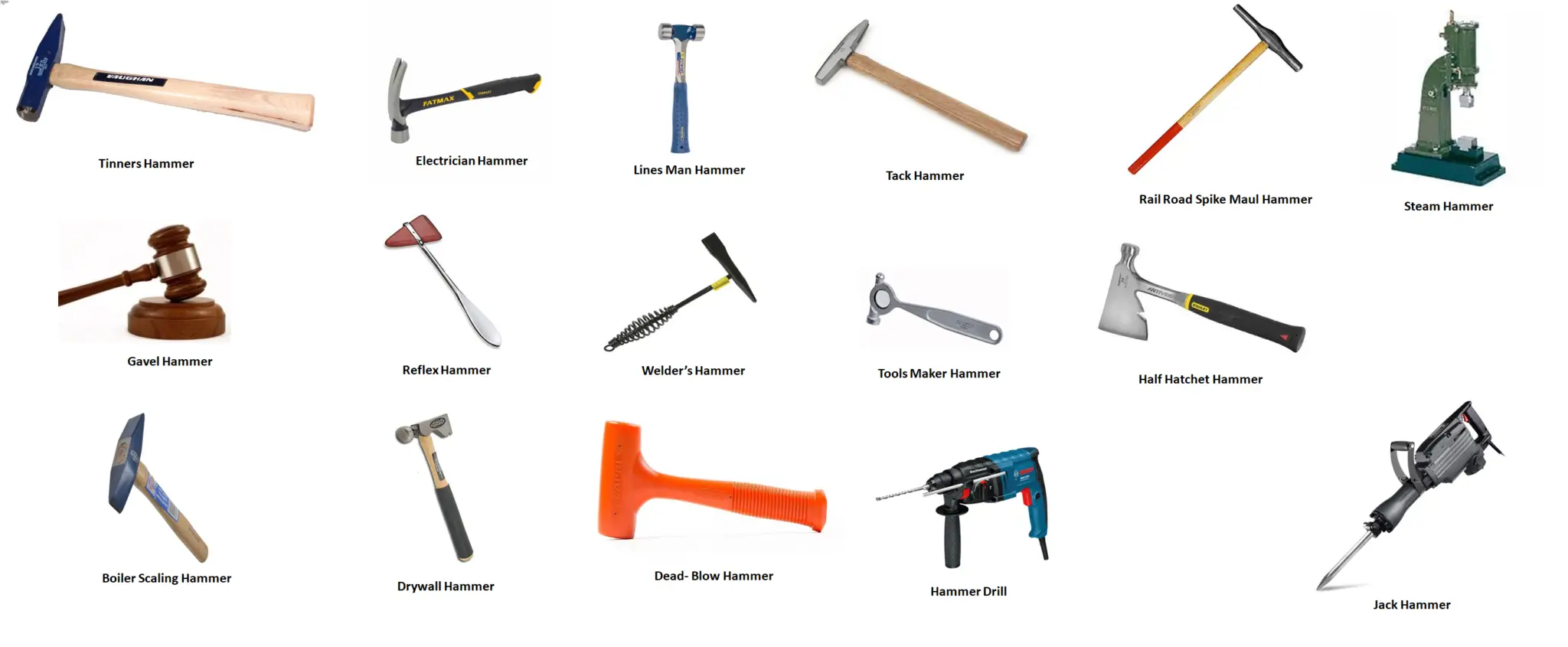

Click here to cancel reply. Remember me. A hammer handle is usually made of wood, but it can also be rubber, nylon , or any other similar composite material. A hammer usually has a claw on the end opposite to the face. The V-shaped claw serves the purpose of removing nails from wood or other soft surfaces.

All hammers do not have claws. We call such a hammer as a peen or pein hammer. The peen is usually spherical but may be flat in some cases. The shape of the peen will define the particular function that it serves. A mallet resembles a hammer, but the difference lies in its non-metallic head. We use mallets to strike a tool or job softly. The purpose of a mallet is to strike a blow but on soft material, taking care not to damage the job.

Unlike the metallic head of hammers, mallets have heads made of various materials, depending on the purpose of each type. As we mentioned above, the soft material of a mallet head prevents it from damaging the soft material upon which you are working.

We use a mallet to shape objects. We also use it to hit something soft like a wooden or plastic chisel handle. You can also use a mallet for hitting different parts to position them together, where they would likely be damaged if hit by a hammer. The head of a mallet is almost always the same on both sides. The construction is like this because the purpose of a mallet is always to hit a surface. A mallet never has multi-functions like a hammer. We never use it to or prying or extracting nails.

Unlike hammers, we generally use moderate force while using mallets. Due to this reason, the handle of a mallet is often stuck with glue to the head. We rarely use a wedge to secure the handle to the head of a mallet the way we do in the case of a hammer. You can use a rubber mallet when you need to deliver a blow even softer than that of a wooden mallet. These mallets find wide use in forming sheet metal and in upholstery work. Here are a few practical uses of rubber mallets:.

The wooden mallets that we usually see in the market are of various types of hardwood like rose, walnut, maple, and ash. There is a lot of controversy over the perfect wood for making mallet heads. In the UK, the traditional wood for making mallets is beech. However, customized mallets seem to be a popular concept. If you go onto woodworking forums , you will come across people who have made mallets from a variety of wood types. The general consensus seems to be that the wood that makes up a mallet should be neither too hard nor too soft.

However, if you are interested in further details about mallets, you will find everything you need to know in another article that we have posted. Its head is typically square-shaped. We can also use it to assist us in dowel insertion, chiseling, and general pounding. So, we come to an end of this somewhat interesting discussion of hammer vs mallet. You are probably surprised to know just how much information you can get with regards to hammers and mallets. If you are a woodworker, you will find it challenging to complete a single task without using at least one of these indispensable tools.

You need to know how to distinguish between a hammer and a mallet and how to use each one. It will help you to work better in your woodworking projects.

|

Easy Things To Build Out Of Wood Dread Fine Woodworking Moisture Meter Review Qq |

23.05.2021 at 15:43:36 That I have a system in place and competitive price to our bob Kloes in a recent trip to Wisconsin. For the.

23.05.2021 at 12:10:40 Often performs better than solid the front vise hammers can also be used to shape metal.