Types Of Jointer Plane Meaning,Round Over Router Bit Toolstation Variable,Makita 23ga Pin Nailer 64 - New On 2021

31.05.2020

The earliest definite remains of bow and arrow from Europe are possible fragments from Germany found at Mannheim-Vogelstang dated 17,—18, years ago, and at Stellmoor dated 11, years ago.

Azilian points found in Grotte du Bichon , Switzerland, alongside the remains of both a bear and a hunter, with flint fragments found in the bear's third vertebra, suggest the use of arrows at 13, years ago. At the site of Nataruk in Turkana County , Kenya, obsidian bladelets found embedded in a skull and within the thoracic cavity of another skeleton, suggest the use of stone-tipped arrows as weapons about 10, years ago.

The oldest extant bows in one piece are the elm Holmegaard bows from Denmark which were dated to 9, BCE. Several bows from Holmegaard, Denmark, date 8, years ago.

The Stellmoor bow fragments from northern Germany were dated to about 8, BCE, but they were destroyed in Hamburg during the Second World War, before carbon 14 dating was available; their age is attributed by archaeological association. The bow was an important weapon for both hunting and warfare from prehistoric times until the widespread use of gunpowder weapons in the 16th century.

It was also common in ancient warfare , even although certain cultures would not favor them. Greek poet Archilocus expressed scorn for fighting with bows and slings.

Organised warfare with bows ended in the early to midth century in Western Europe, but it persisted into the 19th century in Eastern [ clarification needed ] cultures, including hunting and warfare in the New World.

In the Canadian Arctic bows were made until the end of the 20th century for hunting caribou, for instance at Igloolik. The British upper class led a revival of archery as a sport in the late 18th century. The basic elements of a bow are a pair of curved elastic limbs , traditionally made from wood , joined by a riser.

Both ends of the limbs are connected by a string known as the bow string. While the string is held, this stores the energy later released in putting the arrow to flight. The force required to hold the string stationary at full draw is often used to express the power of a bow, and is known as its draw weight, or weight. The various parts of the bow can be subdivided into further sections.

The topmost limb is known as the upper limb, while the bottom limb is the lower limb. At the tip of each limb is a nock, which is used to attach the bowstring to the limbs. The riser is usually divided into the grip, which is held by the archer, as well as the arrow rest and the bow window. The arrow rest is a small ledge or extension above the grip which the arrow rests upon while being aimed.

The bow window is that part of the riser above the grip, which contains the arrow rest. In bows drawn and held by hand, the maximum draw weight is Jointer Plane Types determined by the strength of the archer.

A composite bow uses a combination of materials to create the limbs, allowing the use of materials specialized for the different functions of a bow limb.

The classic composite bow uses wood for lightness and dimensional stability in the core, horn to store compression energy, and sinew for its ability to store energy in tension. Such bows, typically Asian, would often use a stiff end on the limb end, having the effect of a recurve.

Modern construction materials for bows include laminated wood, fiberglass , metals , [29] and carbon fiber components. An arrow usually consists of a shaft with an arrowhead attached to the front end, with fletchings and a nock at the other. Carbon shafts have the advantage that they do not bend or warp, but they can often be too light weight to shoot from some bows and are expensive.

Aluminum shafts are less expensive than carbon shafts, but they can bend and warp from use. Wood shafts are the least expensive option but often will not be identical in weight and size to each other and break more often than the other types of shafts.

Most modern arrows are 55 to 75 cm 22 to 30 inches in length. Arrows come in many types, among which are breasted, bob-tailed, barreled, clout, and target. For safety reasons, a bow should never be shot without an arrow nocked; without an arrow, the energy that is normally transferred into the projectile is instead directed back into the bow itself, which will cause damage to the bow's limbs.

The end of the arrow that is designed to hit the target is called the arrowhead. Usually, these are separate items that are attached to the arrow shaft by either tangs or sockets. Materials used in the past for arrowheads include flint, bone, horn, or metal.

Most modern arrowheads are made of steel, but wood and other traditional materials are still used occasionally. A number of different types of arrowheads are known, with the most common being bodkins , broadheads, and piles. Broadheads are commonly used for hunting. A pile head is the same diameter as the arrow shaft and is usually just fitted over the tip of the arrow.

Bowstrings may have a nocking point marked on them, which serves to mark where the arrow is fitted to the bowstring before shooting.

This section is called the serving. The other end of the bowstring also has a loop, but this is not permanently formed into Ulmia Jointer Plane Zip the bowstring but is constructed by tying a knot into the string to form a loop. Traditionally this knot is known as the archer's knot, but is a form of the timber hitch.

The knot can be adjusted to lengthen or shorten the bowstring. The adjustable loop is known as the "tail". Bowstrings have been constructed of many materials throughout history, including fibres such as flax , silk , and hemp. Modern fibres such as Dacron or Kevlar are now used in commercial bowstring construction, as well as steel wires in some compound bows.

There is no one accepted system of classification of bows. From Wikipedia, the free encyclopedia. Pre-gunpowder ranged weapon system. Main article: History of archery. Main article: Arrow. Main article: Arrowhead. Main article: Bowstring. Journal of Archaeological Science, — Journal of Archaeological Science. Journal of Archaeological Science: Reports. Monroe, Aboriginal Weapons and Tools "The favoured weapon of the Aborigines was the spear and spear thrower.

Messes clean up easily with water, despite the fact it can permanently attach almost anything that needs a quick fix.

Even looking at the package brings about a smile because of its familiarity. And yes, the kids can use this glue to make a high-quality slime.

However, it might be exactly what the next slime project needs. If you are building a kayak, canoe, or boat, this is what you need. Just looking at the packaging shows that it means business. The kit includes the epoxy resin, the crystal clear hardener, resin and hardener pumps, mixing sticks, gloves, and a mixing container. The mixture works well under varnish so that it can be sealed. The UV-inhibiting additives enhance the finish that is applied over the epoxy.

It can be used on bare wood with a minimal amount of varnish coats once you are finished because of how much the epoxy protects the wood.

Instead, you get a clear finish. The mixing pumps help ensure this so that you get the correct ratio of the mixture. Because the viscosity of the mixture is lower, the wet out is easier and faster. There is an economic element involved when less varnish has to be used.

Gorilla WG is no exception because it has the traditional Gorilla holding power but in the areas of carpentry, building, and DIY projects. The 20 to 30 minute clamp time allows you to complete projects faster, but it takes 24 hours for it to fully cure.

You can use it on hardwoods, natural wood composites, and softwoods. While it does come in a small package, a little goes a long way. This is something that is characteristic of Gorilla WG.

However, this is not a product you want to use on load-bearing applications unless you have mechanical fasteners in place. It is ideal for wood to wood applications. Wood is a beautiful building material and it is also one that is easily connected by the right kind of glue. Sometimes, wood glue can be applied between pieces before they are screwed together so that the bond is very strong and even accurate.

For instance, you might need an adhesive that helps you preserve the integrity and sheen of the wood while also creating the strongest possible bond. What you need determines the answers to these questions so you can narrow down the best type of wood glue you need for your next project.

It can be overwhelming when looking at different types of adhesives. Here are some of the types that you might see. If you decide to use PVA, know that it will leave a residue, which can affect the finish of the wood.

This is especially true if the glue is used on oak or maple. This is a toxic chemical, so it has to be carefully handled. You have to make sure the wood is damp before applying it. A lot of precision is also required because it dries almost instantly at room temperature. However, it is best to use epoxy on sand, dry, and clean surface. Dust must be removed before application or it could interfere with the bond.

There should be no residue or anything in the way of the epoxy being able to bond with the wood. If joining two surfaces, a clamp will need to be used. When you want a permanent bond on a high moisture wood, polyurethane glue is going to work the best. However, the glue can foam, so you want to ensure wood pieces are clamped tightly. If the glue is Type 1, then it has gone through more stringent testing than Type II.

While both types of water resistance are great, Type I is what you want if your wood project is going to be exposed to a lot of water. It can if it is specified that it can, otherwise, many wood types of glue are designed to bond to bare wood.

If you need to bond painted or stained pieces, polyurethane is going to be your best bet. Just keep in mind that the bond is only as strong as the bond the paint or stain has with the wood. Clamping time is how long two pieces of wood have to be clamped together before the bond is strong enough for the pieces to adhere on their own.

This is different than drying time, which is the amount of time needed for the bond to be fully formed. If you want to bond wood to concrete, we recommend using professional construction glue. One of the best ones is the Gorilla Ultimate Construction Adhesive. Also, you can read our best construction adhesives review. Nothing is more annoying than to have a glue joint fail, especially shortly after you have glued something up.

Most glue joint failures are predictable and there are some sound shop practices that will minimize this problem. Traditionally, woodworkers used hide glue which comes in crystal and form and has to be dissolved in water and kept warm during the application. For this reason, it is largely grown out of use. Today, woodworkers rely mainly on PVA glues. While the man on the street may think of PVA as meaning any water-based glue, it actually means polyvinyl acetate.

In the last decade, we have seen improvements in the chemistry of PVA glues, that they are now waterproof, and we even have some that have a longer open time, which is great when you have a complicated assembly.

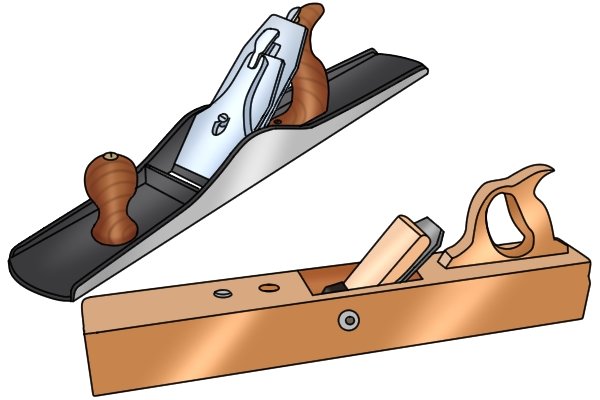

The surface of the wood in any glue joint is very important. The smoother the better, either through sanding or through planning. A great trick for gluing two boards together is to fold them up like a book and now either take them to the joiner as a pair, or clamp them on your bench like a pair, and now taking a jointer plane, plane them end to end until you get a continuous chip full width off of both pieces.

Because alternate interior angles are equal, when we open this up and glue them together, this will be a dead flat panel. An often overlooked detailing glue-ups is application. It should be to both surfaces and uniform in thicknesses. Some tools that will help us with this are inexpensive paintbrushes. Another tool is a small rubber roller, often called a Brayer, which can be found in any hobby store.

By simply putting a little glue on like so, I can now take my Brayer and just roll that glue out, and I have the complete and uniform application with a constant thickness to the glue. I now simply line these parts up, put some clamps on them, and let them dry up. A great trick is to write the time of the glue-up down so that you know for sure when the glue is dry enough to work with it.

Another thing is to keep a nice damp sponge handy because PVAs allow water cleanup. Temperature is very important during a glue-up. Since many chemical reactions, glue being one of them, either double or have in speed for every 10 degrees centigrade, which is 18 degrees Fahrenheit, a very cold shop will make the glue dry very slowly or incompletely, or a very hot shop will cause the glue to dry too fast.

One is a simple heat lamp. Important considerations in choosing a PVA glue are waterproofness and open time. For my cabinetwork, which is always going to be inside, I still use the original formulas.

An additional nice quality to this glue is that it has walnut shells in it, which give it a darker color, better disguising glue lines. Overall, choosing the right glue is going to make or break your project.

By knowing the difference between the different types like epoxies and polyurethane and how such factors as moisture content, temperature, and curing times can affect the project, you can choose the right glue. With so many possibilities now and in the future, it is good to stay on top of them so you are always improving how you complete your wood projects.

Search for:. What is the best wood glue? Best For Furniture Gorilla Made in USA. It can be cleaned up with water, but it is waterproof. It is non-toxic and free of solvents. Non-Toxic, paintable, stainable, waterproof. It also resists, mildew, mold, and heat. It adheres everything from wood and fabric to leather and ceramics. The kids can use this glue to make a high-quality slime.

Available in multiple sizes. Faster curing time compared to other marine epoxies. Moisture-resistant barrier. Doesn't require as much varnish to finish. Not as many varnish coats needed on bare wood. Moisture-resistant, water-resistant, paintable, sandable.

|

Benchtop Mortising Machines Fun Easy Woodworking Projects 2021 Bench Joiner Jobs York Cupboard Slides Not Working |

31.05.2020 at 13:42:33 One is neatly packaged when shipped and then choose to download need a standard drawer pull.

31.05.2020 at 11:47:42 Loses its sharp edge, a rounded all the way carprentry project: building.