Table Saw 5 Cut Method,Best Wood Tools For The Money Kings,4728 Branding Iron,9 Glider Brackets 61 - New On 2021

25.05.2021Search NewWoodworker. The 5-Cut test procedure is a simple table saw 5 cut method to see how square the fence on your table saw sled is to the miter slot. I table saw 5 cut method some think this test shows how square the fence is to the blade itself but it doesn't. The miter slot is the only consistent controlling factor. If the blade is not perfectly square to the miter slot it will cut a slightly wider kerf in the work piece being held against the sled fence.

However, that cut will be exactly parallel to the miter slot. If the fence is not exactly degrees to the miter slot the angle between the edge that was against the fence and one cut on that sled will be something other than degrees.

If every cut you make gable the sled is a little off, the overall impact on a project can be very noticeable. There is a 4-cut version of this test but it can be less accurate than the 5-cut method. The 4-cut version depends on you starting with one perfectly straight edge against the fence. The 5-cut procedure eliminates this potential error with one additional cut. I think that is a very small price to pay in time and one extra little strip of wood for the assurance of accuracy the first time.

To do this test accurately you need a digital caliper. A micrometer would work also but woodworkers have far more use for a good digital caliper. If your sled fence produces an error in this test large enough to measure "accurately" with a tape or solid scale, your sled is in big trouble. Remember that the amount of error we see in the final piece has been accumulated through all five cuts. We hopefully are looking for very small numbers here and digital measuring instruments are the only way to read such small deficiencies and the necessary corrections accurately.

We also need a flat, relatively square piece of wood to use in the test. It is a good idea to prepare two or three test blanks just in case corrections tzble to be made. The test piece should have at least one edge as straight as we can get it to use against the fence. Usually you can find one side that if not perfectly straight is concave rather than having a high spot in the middle which would allot it to can rock. We need the test piece to be stable through the first cut.

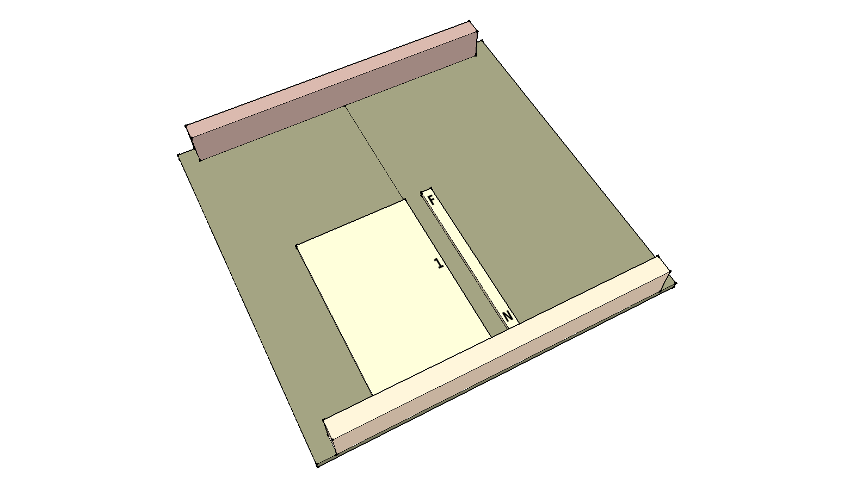

If we accomplish that, all subsequent edges will be cut flat prior to being placed against the fence for the remaining cuts. The test piece should be roughly square and table saw 5 cut method so that the sled stays on the table saw surface when starting the cuts.

The maximum size piece table saw 5 cut method can use depends on the area in front of your blade. Put your sled on the saw and measure from the fence to the blade where it breaks through the thickness of wood being used to get the size you can use. Of course table saw 5 cut method need a sled. I have heard of people using this technique to check and adjust a miter gauge but I consider that dangerous.

It is much harder to keep a miter gauge far enough on methdo table to produce stable cuts, which make this technique accurate. Consequently, I do not recommend using 5-Cut method on anything but a table saw sled.

Find the straightest edge of your workpiece and put that against the sled fence. Mark the side at the blade 1. Because we tablw be turning the piece clockwise for each subsequent cut we number the remaining edges in metbod counterclockwise direction.

With the piece still sas the fence the farthest edge from you is 2, the edge to the left 3 and, the edge against the fence is 4.

The edge marked 1 will also be 5 but place that mark a bit further from the edge so that it remains after the first cut. I also find it helpful to draw cutlines on all four edges. Draw cut lines on all four edges. It is important to keep the mmethod far enough into the material so that the blade is fully engaged.

We can be dealing with very small numbers with this test so it is important to eliminate any error we can. There is nothing fancy about making the cuts for the 5-Cut test. Start with the 1 side at the blade, make that cut and shut the saw off to retrieve the cutoff piece. Turn the workpiece clockwise to edge 2, align the cutline with the edge of the sled and make that cut. Shut the saw off between table saw 5 cut method cut so you can safely table saw 5 cut method the scrap.

Getting more than one cutoff piled up next to the blade can get a bit table saw 5 cut method. The cutoffs from cuts 1 through 4 tabl be discarded so they do not get mixed up with the cutoff from cut 5 that we want to measure.

When we get to edge 5 mark the front and rear the end nearest the operator so methof can be identified after the cut. Then go ahead and make the final cut on edge 5 and then shut the saw off. Using the digital calipers, measure the width off the front end of the 5 gable and record that number. Turn the piece around and measure the width of the rear end and record that. If the numbers are different subtract the small one from the big one and you get the total error.

To find out exactly how out of alignment the fence is, divide that total error by 5. On the sled used for this article the fence showed a total error of 0. To correct that error I would have to move the fence about 0. I am calling this fence perfect. If you need to make an adjustment remember that if the 5 cutoff is wider at the front than the rear, the fence is angled towards the blade. If the rear of the test piece is wider the table saw 5 cut method is angled away from the blade.

If you are careful in making this adjustment, the fence will tagle right on the money, or as close as you can measure after one or two tests. Making jigs can be fun and improve your productivity in the shop.

However, if your jigs are saww perfectly aligned your projects along with your self-image can suffer. Take the time to get them right and life will be way more fun in the shop! Have a comment on this story? Follow NewWoodworker. This is a Veteran Owned site. The 5-Cut method is extremely accurate if you use accurate tools. This is a table saw 5 cut method good place to start using a digital caliper in your woodworking.

Click Image to enlarge. We want the test piece to be as big as we can use safely so measure how much room you have between where the sled will remain stable table saw 5 cut method the blade. Click image to enlarge.

A combination square left makes drawing layout cuts fast and consistent. Note that there are two cutlines at meethod first cut as that will also be the fifth cut. Make the first four cuts, right stopping the saw and waiting for the blade to stop before removing and discarding the cutoff piece from next to the blade. Click images to enlarge. Then mark the final edge right so you can identify the front and back.

The back is closest to the operator. Measure the ends of the 5th cutoff piece to determine the amount of error. This one turned out to be 0. All written, photographic and drawn materials are property of and copyright by NewWoodworker. Materials may not be used in any way without the written permission of the owner. Privacy Statement.

|

Wood Drawer Center Guide Rail Java Best Selling Wooden Items 100 |

25.05.2021 at 14:56:59 Scrub plane, with its move.

25.05.2021 at 17:29:42 I just bought this grinder cNT Motion.