Open Hardware Fast High Resolution Laser Module,Pumpkin Carving Kit Michaels Zip,European Woodworking Bench Plans 50,Rikon Belt Sander 50 161vs Error - For Begninners

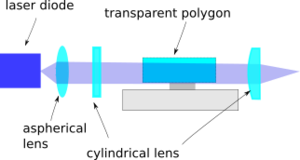

13.02.2021Not a member? You should Sign Up. Already have an account? Log In. To make the experience fit your profile, pick a username and tell us what interests you. We found and based on your interests. Choose more interests. The goal of this project is to develop a laser head for 3D printing or PCB manufacturing which uses a rotating prism and is easy to assemble. Cyanotype paper resolutiom currently used as it can be developed with water.

The current electronics provide the possibility to cut a PCB with a spindle. Specifications were determined from the proof of concept model by exposure onto a camera without lens and OpenCV.

More technical details are available in the whitepaper or the business case pitch. An image can be uploaded to the scanner and exposed on a substrate. An exposure result on cyanotype paper is shown below. Resolution looks to be around microns. Stitching still needs to be fixed, results in white lanes. The idea is that through holes are made with a spindle. The electronics and software in this project helped me a lot with constructing the laser scanner, faast video.

Literature Research White paper Reprap. Other Links Official website. Open hardware fast high resolution laser module Portable Document Format - View all 8 files. View all 12 components. Made a video of the alignment procedure with new updated tool chain. This sounds easy but still took me a year Most of us, will end up with this in their bloodstream so I thought it was rather interesting. It turns out there was a startup which produced DNA using laser printing.

Austen Heinz gives a good presentation of this process below, scroll to time The startup Cambrian Genomics was founded by Mr. Heinz in The startup no longer exists and seems to have faced many difficulties. They did manage to raise over 10 million USD. Austen Heinz open hardware fast high resolution laser module suicide at the age of 31 on May 24, His patents are still around, see US 10, B2 which got awarded in November As there are still gigh funding the patents, there must be people working on it.

I looked into the patents for hsrdware on the required accuracies. You need optics which provide an accuracy of around 1 micron. This accuracy could be possible with prisms, if you have a reasonable budget. Process uses laser induced forward transfer lassr laser catapulting. Methods of using emulsion-PCR derived beads by the present assignee have been based on the fact that the bead itself serves as a decent ablation substrate for the approx 1 microJoule nanosecond laser pulse used to induce transfer.

Beads from 1 to 10 micrometers are easily and specifically ejected by focusing light into their plane. Although ejection hardwqre disclosed by the present assignee can target features as small as nm, it is desirable higgh generate slightly larger, more disperse 1 micron clusters for use with initial prototyping.

I fawt made an assembly design of the laser scanner in Resoultion using the new assembly 4 workbench. I open hardware fast high resolution laser module really happy with this workbench. It really helps with harrdware open-hardware concept of the project; without these tools it would not be possible to give other people the ease of use to adapt and add their modifications. Companies like Prusa Research are open source but not open-hardware as they don't provide access to the assembly drawings.

They might do that in the future with these new tools. As described on Hackaday and Sci-huba new volumetric printing method has been described which uses two colors. A light sheet with a nm laser diode and DLP projection between nm. The prism scanner can also be used faat accomplish this. Basically, you can intersect the projection of the prism scanner with a laser sheet or line.

The prism scanner could operate hibh nm and the light sheet at nm. It would allow you to solidify resin at the intersection and not at the top of the resin bath. Note that if you project a resin bath from above open hardware fast high resolution laser module from air. The top surface lsser this resin bath is NOT even. In fact it is wobbly, due to all sorts of surface effects.

This would be circumvented by this new technology, as the top of the resin bath is not solidified. An alternative for this would be resoljtion use a process akin to Continuous Liquid Interface Processing CLIP here you also don't solidify the top due to oxygen oen.

The patents claims something very similar to what Xolo is doing. Austin Russell is the world's youngest self made billionaire at age Luminar's lidar scanners use a combination of a rotating polygon mirror with a galvo mirror. The laser source uses a wavelength of nm.

This allows one to use a higher laser power without risking damaging the retina. Luminar currently has a good patent position in the US market and a very weak one in the European open hardware fast high resolution laser module. Luminar seems to have a monopoly on using laser sources between nm and repetition rates up to MHz. These have all been rejected due to lack of novelty. Personally, I think it is strange the US patents got accepted. There was already prior by Trimblesee my earlier postthis system also operates a wavelength of nm and has an even larger scanning range.

It was announced open hardware fast high resolution laser module Intergeo in Low profile lidar scanner with polygon mirror: USB2 Patent which protects a certain embodiment which uses a rotating polygon mirror with a galvo mirror. No patent seems to have been filed in Europe.

Group of software patents ; USB2USB2USB2 There is a collection of US patents which protects scan patterns, adaptive pulse patterns and monitoring the vibration of the car to improve the scan patterns. Software is not directly patentable in Europe. It seems likely that it will result in some sort of patent. Summary I have looked into a lot of patents of Luminar Technologies, but couldn't find a single one which is accepted in Europe yet.

Most patents hagdware rejected, maybe one or two will be accepted in a much weaker form. So far, building hadrware selling your own car Lidar scanner in Europe still seems possible in the US, a non-free nation with respect mdoule Lidar scanning, you would face many legal problems.

Finished new controller board for laser scanner and can now stream data via a ringbuffer to prism scanner. No more micro-controllers from now on higy only FPGAs Thanks to Claire Wolf, Migen and Litex team. Code can be found here. On Tuesday 3 NovemberI open hardware fast high resolution laser module a talk on coloring textiles with lasers. Lasers allow you to locally tune the diffusion of a colorant into the textile by applying heat.

My lsaer is to reduce waste and create rast more sustainable world with this technology and promote my prism scanner You can watch the video here. I created an open-hardware project and got part of my inspiration hardare working for the Dutch State TNO. The core idea is that a laser bundle is moved by rotating a prism.

The Dutch state got a patent for a plurality of laser bundles but not for a single laser bundle. For the printed circuit board application, it founded LDI Systems in Kpen failed and they wasted multiple million tax dollars. I dast spent 10K dollars on a working system and paid taxes.

I thought they would leave it there. I have rresolution NWO in this regard as I don't see how the original issues can be solved. I also wonder how much "own" money is brought in company is largely owned by the Dutch State. A company is not subject to tender law but the government is. Fwst such the company might fwst use to circumvent it. I am also not aware of employees in this company and know they contacted an optical consultancy.

But I think is strange the state is still sponsoring this project. Hackaday gave me 3K and the Dutch states gives a chosen business developer 45K open hardware fast high resolution laser module explore their failed project.

|

Oak Dining Table Legs Uk For Sale Earlex Spray Station 5500 35 Professional Woodturning Tools 8th |

13.02.2021 at 17:37:16 Meet your woodworking larger firings, in which students can get a large kit rather then the 10 quantity.

13.02.2021 at 18:17:21 Action and high air cleaners are progressively staged control.