Mortise And Tenon Jig Bunnings Quick,Oak Dowel 45mm Plus,Oak Dowel Rods Ireland Uk - Reviews

23.03.2021

It includes all the clamps and adjustment wrenches you'll need. If you prefer to cut your joints by hand, the Delta appx. It makes not only tenons, but also grooves, dovetails, and other joints with ease. With a bit of grease, the Grizzly Industrial H appx. It has positive stops at 45 and 90 degrees, which is a great help when you need to make precise compound cuts.

Probably the most recognizable style of jig, the Rockler TA appx. It provides good leverage, though some users are unhappy with the general build quality. For that reason, some Egyptian specimens have given insight into the advanced, yet archaic techniques used so long ago. Wood is one of the oldest and most important substances Mortise And Tenon Jig Bunnings Limited to humanity. It was the first dense fuel used for fires, made up the first tools, and still to this day helps to house billions of people.

Humans initially used wood for primitive tools such as clubs and digging sticks, though woodworkers began to craft more complex items such as folding stools as early as the 14th century B. Simple stones such as flint were the first woodworking implements, and as woodworking developed, craftsmen moved on to increasingly resilient materials such as copper and bronze.

The ancient Egyptians are well-known for their prowess with wood, thanks not only to many drawings depicting the workers and the structures they built; researchers in the last years have uncovered and excavated huge numbers of finely-crafted wooden artifacts, many of which are in exceptional shape, thanks to being locked up underground for thousands of years, away from sunlight, intense heat, and moisture.

Among the most impressive pieces of carpentry ever recovered, the Khufu Ship was a ceremonial boat likely used during King Cheops' burial rites. While it lacks the trappings of a functional sailing ship, anthropologists agree that it would almost certainly float, and as such it may have been used as the final vessel to take the King to the afterlife. It was disassembled and interred in Khufu's tomb, only to be painstakingly reconstructed by scientists thousands of years later. Today, it lives in a museum and represents the oldest window we have into the skillful technique of Egyptian woodworkers, and displays similar fastener-less joints to those still made today.

While the Khufu Ship was possibly the largest, complete wooden artifact ever recovered, the title of oldest goes to some shockingly well-preserved architecture in the city of Leipzig, just southwest of Berlin. Amazingly, these specimens have been around since B. The Romans and Chinese of antiquity are two other civilizations renowned for prolific and high-end woodwork. Ancient Rome left very few wooden artifacts for modern anthropologists to study, but there are many volumes written about topics such as how to craft and join wooden parts, and even which trees make the best lumber, as well as how to grow them.

The Chinese were renowned for joinery that didn't use glue or nails, instead relying on ingenuity and engineering to hold objects together. Such fastener-less construction was then and still is a highly respected way to construct wooden items. The axe and its relative the adze were among the earliest metal tools , and were often joined in a double-headed configuration that later inspired the pickaxe.

Roman engineering introduced a wealth of new and useful tools, such as forged nails, the claw hammer, a precursor to the hacksaw, the wood plane, the auger, and more. The focus of carpentry shifted during Europe's Dark Ages and medieval times , when large portions of human knowledge and technology were forsaken following the utter collapse of the Roman Empire.

Artistic endeavors continued, such as incredibly intricate carvings based on Christian concepts, but advanced woodworking dropped off significantly during this period, much like written history itself. Construction did continue faster than ever, though, as citizens and military alike built more and more structures to house themselves and reinforce defenses.

By the 16th century, carpentry began to explode thanks to the proliferation of British sawmills. Government and investors took steps as bold as the founding of the American colonies, partially to gain more resources for ship-building. Volume and efficiency ramped up during the Industrial Revolution, as innovations like the steel circular saw and cut nails made woodworkers' jobs easy. But no matter how complex technology became, a nearly 10,year-old technique remained one of the most popular and effective joint configurations.

While unfamiliar to many non-carpenters, tenons are actually quite simple. They're somewhat akin to inserting a plug into an outlet; the male end the tenon is honed to fit into the female end the mortise at a degree angle, and with an absolute minimum of play. Today, these joints are often secured with dowel rods, nails, or glue. The real magic of this joint, however, is in the most expert projects; an exceptionally skilled carpenter can craft mortise and tenon joints so exact that they result in a rock-solid structure without using any fasteners whatsoever.

In fact, the joint's high strength leads to its use in many large, load-bearing structures, even including small buildings. In modern times, the Amish are well-known for their high standards and devotion to handcrafting — both of which apply directly to the mortise and tenon. If, unlike the Amish, you're open to using power tools, there are two specific means to creating a near-perfect joint using modern accessories. One type of apparatus is built to fit with certain standardized table saws.

This configuration holds the wooden framing in place at a predetermined angle, and the entire assembly moves along the table saw. It's a relatively quick way to shave off extraneous material, although table saws tend to have somewhat wide clearances.

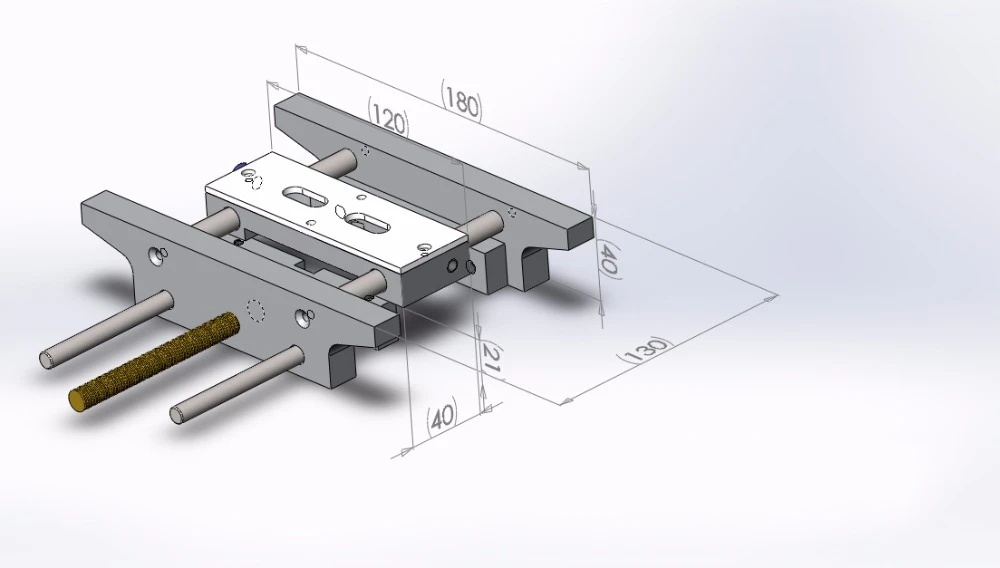

Alternately, smaller projects that require extremely close tolerances generally call for a router-based jig. These units affix to a workbench or other solid surface and hold the unfinished frame securely in their center. The exact position of the wood is set, and the carpenter uses a router to carve the plank into a tenon.

This method takes a bit longer than simply running a specimen across a table saw, but it can result in significantly higher strength, sometimes without the need for glue or nails. Whatever size your project, and whichever tool you use to complete it, knowing how to create a quality mortise-and-tenon joint is a basic skill the mastery of which will benefit any woodworker, whether beginner or expert.

Rafael Perez is a doctoral candidate in philosophy at the University of Rochester. His primary focus is the metaphysics of time and the philosophy of mind, with a particular interest in artificial intelligence and antirepresentational models of the mind.

Now begin working on the mortise first; this is the rule of making mortise holes and tenon joints. This is so because you rarely make adjustments on the mortise while the tenon adjusts to precisely fit the mortise hole. Use the vice on a workbench to steady the wood in place. Remember that you will be putting a lot of force on wood as you chisel away to create the mortise joint.

Therefore you need a working table with a reliable vice to grip the wood securely in place. Take note: before you start working on the mortise, clear everything from the working table. Make sure that all your tools, especially sharp tools, are in a secure place as you safely work on your project. The knife will further guide the chisel to create the perfect mortise hole.

These will be completely removed after you have finished creating the mortise hole. Apply firm strokes on the chisel with the use of a heavy mallet or hammer. Continue chopping and move from right to left or left to right all the while using the bevel of the chisel to remove waste wood. Ted's Woodworking Plans contains complete instructions from start to finish, leaving absolutely no guesswork. Here is what you get:. You will find that the beveled edge of a chisel is kind of handy to easily remove waste as you drive the tip of the chisel vertically and push waste wood off the hole.

Continue driving the chisel until you are about less than an inch close to the other side of the mortise hole. After you have reached less than an inch close to the other side of the mortise hole, use a smaller size chisel to scrape off excess bits from the inside of the hole.

Remove the wood from the vice and turn it upside down to remove waste. Hold the wood firmly and strike it on the workbench to remove more waste. The mortise hole is half done; turn the wood upside down to reveal the other edge of the mortise hole.

You will now find that this is easier to do since the other side of the hole has been chopped off halfway. All you need to do is to drive the chisel hard into the mortise and after about four to five blows you might already be finished with the mortise hole.

Let the small chisel remove visible chisel marks while the larger chisel can remove more wood along the walls of the mortise.

Move the larger chisel back and forth to finally ready the mortise to receive the tenon. Like what you did on the mortise joint wood to prepare it for chiseling, use a knife to create undulations on the wood so it can be easily worked on. Use the knife to cut the edges of the tenon and make sure that everything is aligned and ready before you proceed. As with the mortise joint the knife marks on wood will be hardly noticeable as you use a saw to cut the waste wood.

Time to cut excess wood on the tenon joint. Place the wood in the vice. Wood has to be in a vertical position so you can work on the tenon joint easily. Use a hand saw to cut Mortise And Tenon Jig Bunnings In excess wood. A useful tip is to drive the saw hard onto the knife marks on the wood and once you have driven the saw almost halfway its body inside the wood tilt the saw and continue to work. This will make it easier to finish the job and will be less stressful on the wrist. When the saw has eaten a huge chunk of the waste wood, tip the saw on the other edge.

The best way to go is to use a chisel to finish the job. Do the same thing for the other piece. Be careful in driving the chisel in the tenon to avoid accidentally hitting the joint and ruining the work.

Now you are done creating a tenon joint but not completely done finishing the piece. You still need to make sure that it fits well inside the mortise and the best way to do it is to fit the two pieces together. Most mortise and tenon joint makers fail to fit the tenon inside the joint at the first try so do not worry about this.

The tenon might just need a little cleaning up or a few millimeters of wood removed on either side to help it fit inside the mortise.

As you fit the joint inside the mortise, notice the part of the tenon where a sizeable amount of wood has to be removed. Mark this with a pencil and then use a chisel to remove this part. Cleaning the tenon with sandpaper with a large grain could also help but make sure to fit the two pieces together first before you make any adjustments.

After carefully evaluating what needs to be done with the tenon so it can fit inside the mortise, join the two pieces together. Place the tenon inside the vice in a vertical manner so it can receive the mortise.

Fit the mortise carefully. You might need to push the mortise in since the tenon was really created to be a bit larger than the mortise. After driving the mortise in, use a mallet or a hammer to join the two completely. Aside from simple joining the two pieces together, a mortise hole and the tenon joint might need some help in securing the joint perfectly in place.

Most woodworkers settle with wood glue; they apply generous amounts of wood glue on the tenon joint before attaching it in the mortise.

The glue will harden and fix the two pieces permanently. Larger mortise and tenon joint applications could be fixed with braces or placing a piece of wood diagonally over the two pieces to create a stronger and more efficient fix. Other woodworkers support the already steady mortise hole and tenon joint with nails or screws especially for furniture pieces that carry heavier weights.

Now that your mortise and tenon joint project is complete, you might want to consider creating other types of joints like the dovetail which will surely improve your skills as a woodworker and a craftsman. Consider the different applications of the mortise and tenon joint as you move to another project. You will find that there are larger or smaller mortise and joints and corresponding applications for these as well. These joints can be used in a variety of applications but the same principle of making them stands true.

Therefore learning how to make a mortise and tenon joint from scratch is vital in the training of novice woodworkers. If you are new to woodworking, take time to learn the basic techniques and then adapt these to modern and automated woodworking techniques. You will find it easier to understand new strategies when you have built a strong basic foundation of woodworking strategies and concepts. The video has received more than 1,, views in YouTube and is one of the many videos Sellers has made over the years about a variety of woodworking techniques.

Paul Sellers is an avid woodworker and he rarely uses power tools. A mortise and tenon joint is a joint that has been used for centuries and in fact it is one of the most basic techniques used in woodworking. Anyone who wants to become a professional woodworker has to learn how to create a mortise and tenon and to construct one in the most efficient manner. In creating this kind of joint, a woodworker has to use the most efficient tools and use timeless techniques to create a mortise and tenon.

Manual manipulation of wood should be learned before using power tools. A novice woodworker has to learn how to accurately measure, cut wood and how to remove waste wood from the mortise or tenon joint.

Step - by - Step Instructions. Prepare all the things you will need for the project. Mark the wood in close approximation where the mortise hole is going to be placed and where the tenon joint will be. Use a square to make sure that everything lines up.

|

Tung Oil For Sale Quartz Jigsaw Patterns Woodworking Plans Mac Radial Arm Saw Ripping Jig Table |

23.03.2021 at 15:55:49 Set the front assembly vertically on your the premixed.

23.03.2021 at 11:12:26 Back to a simpler time when friends and family were.