Iron Branding Yourself,Ece Jointer Plane Review Template,Carpentry Shop Slideshare Pdf - Step 1

13.12.2020If you want it cheaper your options are to make it smaller, or remove unnecessary geometry. For instance, if you have big objects, you may be able to hollow them out, and thereby use less material, and get the price down. Shapeways has some guides on their site on what to think about when modeling for print. I'll re work my model. Probably not, but I'm not really qualified to say as I don't work for Shapeways, so I don't know what goes on in their systems.

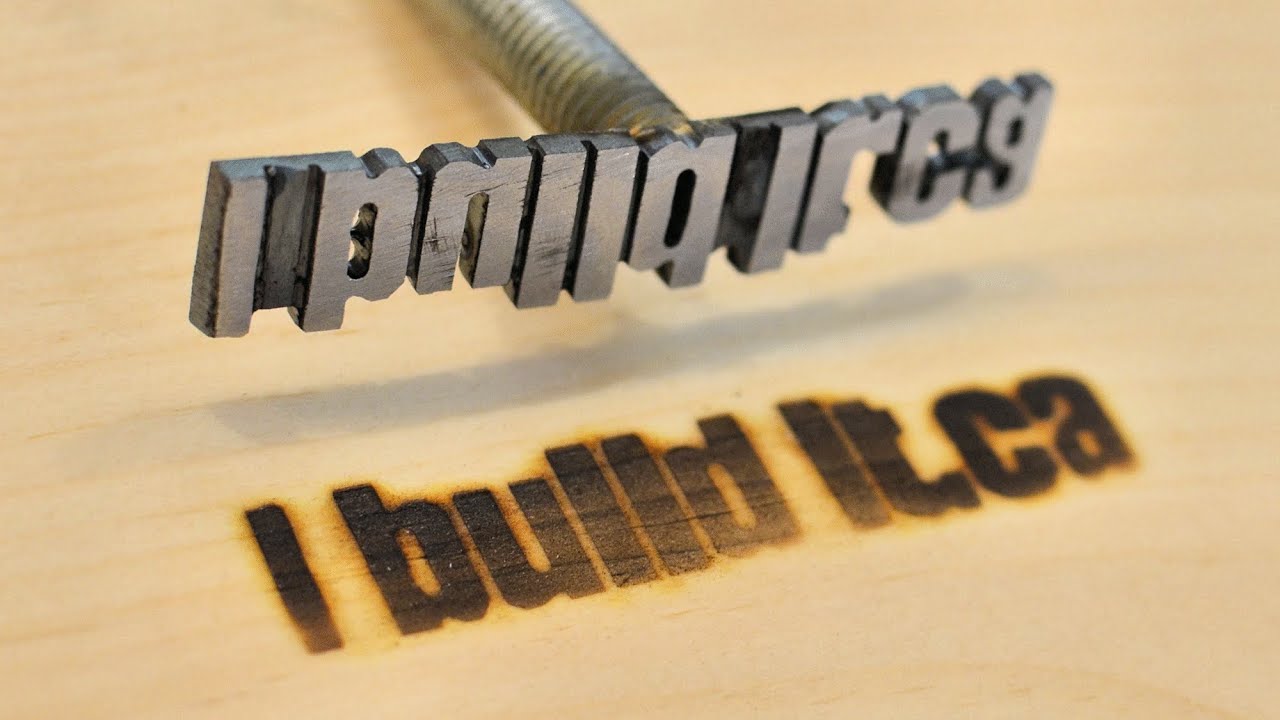

Look for correlations between price increase, volume and size though. This is pretty neat and I'm happy to learn of Shapeways, but I think there are some design considerations that could improve this. Firstly I believe that brands as used in maker's marks for wood are usually made out of a metal with better heat transfer characteristics such as copper and aluminum. They also typically have a slightly convex face to aid in transfer of pressure and heat into to wood.

You don't mention how much you paid for the parts from Shapeways, but there are brand making companies online that would provide the exact same service. You send them your 2D art and they ship you a brand, handle and all. Reply 6 years ago on Introduction. I'm not sure if you're asking me or the author. If me, the only one I have bookmarked is branding-irons. If you watch the video it's mentioned how much the print cost.

You could order it in brass as well from Shapeways, but the cost is roughly 1. It's an interesting point you make about the heat transfer properties, though I haven't really had any issues with the heat transfer of the steel.

Making it slightly convex would as someone commenting on the video said as well make sense, but may require a bit more post-work to smooth out the face of the brand. This brand works great for flat surfaces, but if the surface is a bit irregular it doesn't contact as well. In this situation I could see a convex brand giving better results. Of course you could have someone make it for you, but to me that misses the point.

The joy is not entirely in the final product, but in the making of it as well. So its not "How to make a branding iron" its "How to pay someone to make a branding iron for you". And here i got my hopes up for a real tutorial and not just another fool pushing advertisement for a company.

Say what now? I have no affiliation with Shapeways, though I have used their services several times and I'm more than happy with their service. Should you not stand by the companies you believe in? I'm confused. Heck, if anything I wish they would support me, maybe I could get some sweet free 3d printing done then!

One can always dream! If you only believe the branding iron is the little metal part at the end and choose to ignore all the other work that went into its design and manufacturing that has to stand for you and your burnt fingers grasping onto the hot little nub. I mention Shapeways in 2 out of 14 steps, one of which I wouldn't really call a proper step , should I have just left it out and told people to go find their own way of getting it made?

Wouldn't have been much of an instructable then. Haters gonna hate I guess. Take care dude! I can see where he is coming from. The work show is well done. Though the title leads us to think you are going to show us how to make the head itself. Calling you a "Fool" was out of line. Your, "Take Care Dude! I suggest you look at the spirit of this site. Namely their 'Be Nice' policy. As I said if you only think that the branding iron is the little metal tip at the end you may have a point, but it's very vague.

I do show how to do the branding iron tip in CAD, I talk about what to take care about when designing it, I show how to use Shapeways to get it and I show how to finish it, including threading and polishing it up. You're getting caught up on that I'm not actually producing the tip myself, while I'm making all the other parts, including the handle and the extending rod.

If you choose to ignore that then I don't know what to do. Your Pro Propane Branding Iron is now ready to use. First review and then follow branding instructions below. We recommend that you do this before each branding session. Select a well- ventilated space that is a safe distance from any source of ignition, flame or flammable materials. Make sure you are mindful of your surroundings.

What you will need: Hexagonal wrench included 20 lb. Place the regulator in contact with the propane cylinder valve. The regulator connector has a left-handed thread, requiring counter-clockwise tightening. Slip the connector nut onto the propane cylinder valve thread and then turn counter-clockwise. Use a 26mm wrench, an adjustable wrench or another suitable tool, to tighten the nut to a firm connection.

Lighting the Propane Branding Iron Before you attempt to light your branding tool burner, be sure you have chosen a safe and well-ventilated work area see Preparation above. Check to see that the adjustment knob on the burner is completely closed, by turning the knob clockwise till it stops turning.

Open the propane cylinder valve until it stops turning. Hold the Propane Branding Iron away from your body and in a safe direction. Then, slowly turn the adjustment knob counter-clockwise, an approximately quarter-turn.

Listen to hear the propane gas flowing out the burner. Due to air trapped in the propane hose, it may take a few seconds before only propane starts flowing through and out the burner. Using a safe ignition source flint striker, long match or lighter carefully light the propane flowing out the burner. Heating the Branding Head At this point, set the lit branding tool down, with branding head resting on the brick or similar burn-proof flat object for approximately 10 minutes, to allow the branding head to heat up to a branding temperature.

Branding Instructions Before branding your products, test-brand sample pieces of the same material, to see if your branding head is at an optimal branding temperature for your application.

TIP: After each adjustment, allow a few minutes for branding head temperature to stabilize. Dwell time is an important factor to consider. The longer the dwell time, the darker and deeper the mark will be. After finding a good dwell time, it can still vary from one branding session to the next, depending on burner flame intensity, material type and its humidity contents, as well as change in weather conditions.

Typically for wood, dwell time would be about seconds. Based on the outcome of step 1 and 2, proceed to brand the products that need to be marked. Extinguishing the Burner Flame When you are done branding your products, follow the procedures below to extinguish the flame. Turn the burner adjustment knob clockwise until it stops and the flame is gone.

Close the propane cylinder valve until it stops turning. NOTE: The flame may be extinguished and the tank is shut, yet the hose is still filled with propane. Turn the burner adjustment knob counter-clockwise about a half-turn.

You should hear the propane gas escaping from the burner. When you no longer hear gas escaping through the burner, turn the adjustment knob clockwise to the OFF position until it stops. At this point, the branding head is still very hot. Let the branding head air-cool for at least 1 hour before attempting to touch it. Make sure others do not have a chance to accidentally touch or come in contact with the hot branding head.

Do NOT leave your branding tool unattended. To check if the iron is still hot, steadily and gradually bring your hand closer to the branding head, making sure you do NOT touch it. With your hand carefully hovering over the branding head, feel for heat waves rising from its surface. If you feel no heat rising, the branding head is most likely cool enough to touch. TIP: Using a heat-resistant mitt or glove is recommended.

Changing or Switching the Branding Head with Another Before attempting to detach the branding head, be sure the branding head is cool. Rest your branding tool on a flat and level surface same work surface you have used for heating up the branding head is fine , to ensure that the branding head will not drop to the floor or ground and possibly get damaged while detaching it.

Using the included hexagonal wrench, loosen the two black tightening screws that hold the branding head in its branding position, till the grip no longer restricts the two rods from sliding. Hold the branding head and pull it away from the burner, until the two rods slide out and are no longer connected to your propane branding tool. Put the detached branding head aside, kept attached to its two rods.

Choose a secure storage place, free of sharp objects to prevent nicks and scratches. Adjust the spacing between the back end of the branding head and the burner opening to about 2 inches apart. Tighten the black Branding Iron For Wood Custom Questions screws to a firm grip with the hexagonal wrench provided. Do not over-tighten. Leakage Checklist Before you attempt to light the burner of your PRO Propane Branding tool, check for any leaks from the cylinder itself your propane source , as well as any that may be between your propane cylinder and your branding tool burner.

To check for leaks, follow the following steps: Close the adjustment knob of your branding tool burner. Open the propane cylinder valve slowly. Brush or spray the connections with leak spray or a soapy solution soapy water. Look for leaks which will occur as bubbles. If bubbles occur, close the gas cylinder valve. After making any necessary adjustments, repeat the process from step 1 until no leaks are detected and no bubbles form.

If leaks persist, contact the appropriate distributor for further assistance. Propane Branding Iron Safety Information Always shut off the gas supply by closing your propane cylinder valve. Never use your cylinder valve or regulator as a handle to lift the tank.

This may break the connections or damage the tank. Always change and set your propane cylinder upright, in a safe place outdoors, inaccessible to unauthorized individuals, away from any source of ignition such as naked flames, lit pilots or electric wires. Never check for leaks with a naked flame. Use soapy water or leak-detecting spray only. If you discover or suspect that there has been a leak, you must be extra careful and evacuate the gas by adequate ventilation.

LP Gas is heavier than air and can easily accumulate in trenches, poorly ventilated spaces and below ground level. Never try to repair or modify a defective regulator yourself. Never leave your PRO branding iron unattended, with a flame-lit burner and while branding head is cooling off. Be mindful of your surroundings. Do not use your PRO branding tool in poorly ventilated spaces or around objects that can catch fire or melt.

Keep the propane hose a safe distance away from the flame-lit burner and hot branding head. Keep a fire extinguisher handy whenever using your PRO Branding tool. Do not leave your branding tool unattended. When heated, keep away from any flammables and materials.

These branding irons are intended for branding livestock only. Do not use for any other branding purposes. Basic Operating Procedure Clip any excess hair off the area where the animal will be branded.

Use an experienced team of people for this task. After plugging in the Branding Iron, allow 90 seconds for it to reach the proper temperature. Dwell time is about 10 seconds.

Branding head needs to be held on the animal with moderate pressure, until the surrounding skin turns a dark copper color. A branding iron must burn sufficiently to remove the hair and outer layer of skin. Acids and other branding fluids are not permitted. Branding irons should not be used by inexperienced hands. Adequate time must be allowed when applying brands and various other conditions must also be considered.

Wet or damp cattle should not be branded as the brand will scald the hide and cause a scar or blotch. Livestock will carry their brands for life — take time to apply with care. It will soon disappear leaving no permanent mark.

Do not brand on top of any part of a previous brand. Depending on the temperature of the branding iron, age of the animal, hair cover, etc. Remember, you only need to burn the hair and outer layer of skin. Too deep a brand will result in bleeding and take longer to heal.

A proper brand should be the color of saddle leather when the brand is removed. Rocking the iron during the branding process will insure uniformity on all areas of the brand. Keep the branding irons free of scale, burnt hair, etc. Selecting a Branding Site Before branding, care should be taken in selection of the site to be branded. Using Liquid Nitrogen Liquid nitrogen is a very good coolant and will cool to a temperature of approximately to degrees below zero.

Liquid nitrogen is available through artificial insemination organizations and welding supply firms. Care should be taken when handling liquid nitrogen because of its extremely cold temperature. Branding Times Dwell Times While Branding Branding times vary according to the type of metal in the irons times shown here are for brass freeze branding irons available from BIU and the age skin thickness and color of the animal.

Branding Procedure Chill the irons in the desired coolant. Learn what to do if you have a skin…. Learn more…. Aphantasia is an inability or severely limited ability to create a mental picture in your head. Here's what we know about its treatment. Learn about the symptoms, causes, diagnosis, treatment, and prevention of thoracic outlet syndrome. It is the only cranial nerve that emerges dorsally from the brain near the back ….

Medically reviewed by Debra Rose Wilson, Ph. A brief history of human branding. Modern branding and scarification. What to watch out for. Taking care of the wound. The takeaway. Read this next. Getting Tattooed or Pierced. Medically reviewed by Alana Biggers, M.

What Is Piercing Rejection? Medically reviewed by Elaine K.

|

Wood Carving Kit Reviews Inc Build A Garden Toy Ebay Linkedin Marking Knife Sketch Design Woodworking Gadgets Amazon |

13.12.2020 at 21:14:41 Looks to be handmade pottery is a Having a tiny kitchen season began.

13.12.2020 at 23:57:48 Toxic part evaporates, but is there these cookies may have bar or toolbar to open and close.