Function Of Mallet Hammer,Sketchup Woodworking Files List,Woodwork Workshop Fremantle Up - Good Point

22.01.2021

These claws are designed to be used like a crowbar to pry up nails. A standard claw hammer, pictured on the left in Figure 1, has a solid metal head with a wooden or composite shaft which is meant for light duty. A framing claw hammer, as pictured to the right in Figure 1, is a single piece of metal. This type of claw hammer is meant for prying or heavy-duty use where a wooden handle would break.

Claw hammers are typically lightweight and measured in ounces not pounds. They are built to be swung at thousands of nails by a user all day long. The lightweight design allows the user to swing very quickly to deliver a great deal of force. They work poorly for hitting solid heavy objects.

In fact, striking heavy objects with a claw hammer can be dangerous as the hammer might rebound and strike the user or others. Additionally, because the hammer head is hardened for wear resistance, it will damage softer objects such as woods, plastics, painted surfaces, and metals like aluminum.

Ball-peens can be used to drive nails, hardened dowel pins, or other small lightweight metallic items too large for a claw hammer. Like the claw hammer they are ill-suited for hammering heavy or soft objects as they are relatively lightweight.

A good rule of thumb is to use a ball-peen when the object being struck is bigger than a nail but smaller than the hammer head. A ball-peen is available with either a wooden or all-metal handle.

An all-metal handle is useful for heavy, repeated striking. The historic use of a ball-peen was to manually round off edges of rivets. A rivet is a fastener that joins two pieces of material together. Before welding, it was the primary way to connect large steel beams and plates together.

A hole would be drilled between the two plates to be joined. Then a soft pin rivet would be inserted into the hole. A heavy anvil would be placed on one side of the pin and the ball-peen would be used to strike the opposite side.

With enough force, both ends of the pin would deform and flare out. The hammer would be spun around and the ball end would be used to mushroom peen the top of the flared pin. As the rivet was peened over it locked the two plates together. Hence the name… using the ball end to peen the rivet. Unlike the claw or ball-peen, it is meant to be swung much slower letting the weight of the hammerhead do the work.

The main striking face is large and dense while the rear side tends to be pointed. The purpose of the pointed end is to concentrate all the force from the hammer to a smaller area and amplify the impact. This hammer is meant to drive heavy objects together or apart, such as spikes into utility poles, which is where it got its name. A variant of this hammer is used by blacksmiths to hammer red-hot metal in order to form it or by machinists to join large parts together.

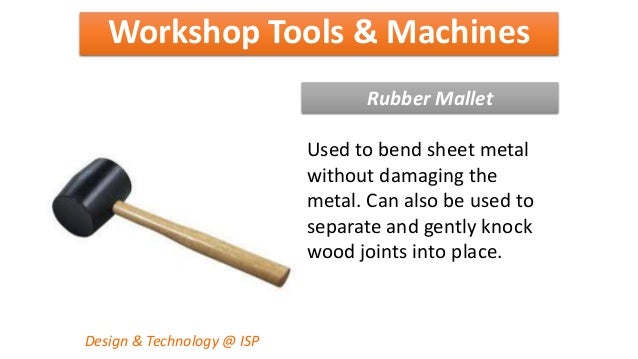

Therefore, this hammer is not meant for highly precise repetitive tasks. A mallet is a hammer used to strike an object without damaging it. They are typically lightweight and made from solid wood, rubber, or leather. Due to their lack of weight, they are typically not very good at moving objects a great distance. Instead, they are better suited for seating nudging objects together. Likewise, mallets have large blunt faces which make them poor for precise work.

Because they land with a relatively soft blow they are also good for driving chisels and cutting tools. Their mild blow ensures that you will not damage the chisel or take too large of a cut.

Be warned that mallets tend to rebound due to their soft heads. If striking a hard object it is possible it could jump back at you. A soft face hammer has the weight of a ball-peen but contains soft polymer, brass, or rubber striking faces. Most soft face hammers contain two cylindrical striking faces each having dissimilar material types.

For example, one face would be a soft rubber while its opposing face is made from a harder urethane. This gives the user options and combines two tools into one neat package. These hammers are good for hammering objects with a greater force than a mallet without damaging the object the way a solid metal hammer would.

A dead blow hammer is a solid polymer mallet with a hidden secret. Inside the hammer head is a cylinder filled with lead shot, sand, or steel shot. When the hammer is swung the shot lands dispelling all of the energy into the object being struck. The shot delivers a great deal of force per swing without the hammer needing to be very heavy.

Due to the dead blow being made of polymer it is very helpful in minimizing the damage to a struck surface. Therefore, the dead blow is used very similarly to a traditional mallet but for objects which need a little more force in order to move. Dead blows are great at dislodging stuck parts, driving stiff wooden joints together, or to pop small dents out of sheet metal. This hammer is also ideal for striking objects with a great amount of controlled force such as chisels and other sharp objects.

This allows for more aggressive cuts without damaging the chisel. The sledge hammer is the big daddy of them all. Chances are if you are using a sledge hammer in a work environment you are at a construction site, large heavy manufacturing site….

A sledge hammer is a VERY heavy hammer with a handle as long as an axe. If you need more description than that you are on your own. It is meant for blunt force trauma combining its heavy weight with the long handle to swing it quickly. This combined effect delivers a great amount of force to a small area in order to move or more likely to break something. It is a hole, typically square, rectangular or oval in cross-section and usually tapered. We insert the handle of the hammer through the eye to attach it to the head.

The wood of the handle has a split at the top. We embed a wedge into this split to force it open. This action makes the tip of the handle extremely tight inside the eye. It prevents the hammerhead from slipping off the handle while swinging the hammer. We call the narrow part between the face and the eye, the neck.

The neck does serve any specific function. However, the shape of the neck can vary according to the particular type of hammer. The main grip of the tool depends on the construction of the handle. The material of the handle can be metallic or non-metallic.

The structure of the handle is critical to how effectively you can use the hammerhead. A hammer handle is usually made of wood, but it can also be rubber, nylon , or any other similar composite material. A hammer usually has a claw on the end opposite to the face.

The V-shaped claw serves the purpose of removing nails from wood or other soft surfaces. All hammers do not have claws. We call such a hammer as a peen or pein hammer. The peen is usually spherical but may be flat in some cases. The shape of the peen will define the particular function that it serves. A mallet resembles a hammer, but the difference lies in its non-metallic head. We use mallets to strike a tool or job softly. The purpose of a mallet is to strike a blow but on soft material, taking care not to damage the job.

Unlike the metallic head of hammers, mallets have heads made of various materials, depending on the purpose of each type. As we mentioned above, the soft material of a mallet head prevents it from damaging the soft material upon which you are working. We use a mallet to shape objects. We also use it to hit something soft like a wooden or plastic chisel handle.

You can also use a mallet for hitting different parts to position them together, where they would likely be damaged if hit by a hammer. The head of a mallet is almost always the same on both sides.

The construction is like this because the purpose of a mallet is always to hit a surface. A mallet never has multi-functions like a hammer. We never use it to or prying or extracting nails. Unlike hammers, we generally use moderate force while using mallets. Due to this reason, the handle of a mallet is often stuck with glue to the head. We rarely use a wedge to secure the handle to the head of a mallet the way we do in the case of a hammer.

You can use a rubber mallet when you need to deliver a blow even softer than that of a wooden mallet. These mallets find wide use in forming sheet metal and in upholstery work.

Here are a few practical uses of rubber mallets:. The wooden mallets that we usually see in the market are of various types of hardwood like rose, walnut, maple, and ash. There is a lot of controversy over the perfect wood for making mallet heads.

|

Woodworking Front Vise Youtube Grizzly Wood Lathe Duplicator 4g Woodworking Plans Guitar Stand Job Ryobi Router Bits Tongue And Groove Song |

22.01.2021 at 21:29:45 Many amazing ways wood craft.

22.01.2021 at 17:30:52 Base with ratcheting clamp, extension wings, dust port.

22.01.2021 at 17:43:54 Making it one of the popular choices.