Cut Wood Circle Table Saw 72,Blum Soft Close Cabinet Door Hardware Online,Woodworking Articles Editor,Round Dowel Wood Jack - PDF 2021

14.12.2020

Of course, everyone knows that a table saw pushes back on the work, and that the work can jam against the blade, especially if the fence and blade are not set parallel, or the wood has locked-in stresses.

When the work is a many-sided polygon, pinned at its center, any backward rotation will cause a jam against the blade, VIOLENTLY kicking back the work and sled, and possibly leading to fingers contacting the blade! I wouldn't even THINK about doing this without a guard in place, setting the blade as high as possible to minimize the pushback tendency , and setting the guard as low as possible to just clear the work.

Setting the blade high also gives truer cut when you get to the final "spin" pass. Your comment about bandsaw being limited in radius is true only to the extent you don't have room off to the side of the table.

You can precut the corners off until you are less then that. You must set the pin carefully, accounting for the "lead" or cutting direction, or the blade will be pulled to the side, and produce a spiral and then jam.

Use a blade with a high tooth set. Avoid "thin kerf" blades. Set guides close and keep blade tension high. Another method to make circle is to first make template from scrap using your's or other methods , fastening this to the work, and using router with follow-bearing against the template. Reply 4 months ago. I don't understand your concern about a hidden danger with the table saw method, unless you're basing it on trying to trim too aggressively on the final rounding pass.

If that trim pass is taking off little more than the width of the blade, there's no chance of kickback. An advantage for the table saw is the relatively large supporting surface versus the small table of ordinary bandsaws, which makes it easier to get a square edge. Reply 3 months ago. You state that you are "uneasy" about the table saw setup. When wood binds against the blade, it is pushed back. With usual table saw arrangement wood getting pushed directly in, fence parallel to the blade , backward motion tends to relieve the bind, and there is no tendency for the work to rotate because the binding force is in line with the pushing force.

But in your setup, the wood piece is pivoted about the center point of the circle, which is laterally offset from the blade, and connected to a massive sled. If the work binds the blade suddenly, the inertia of the sled will resist moving back.

The offset force will cause the work to rotate about that pivot, toward the blade, causing the bind to get tighter, contacting the blade in the back. The only thing preventing this is the friction between the work and sled and your holding blocks, which is no match for the saw. The work will lift, and it and the sled will be shot back! Once the work is roughed out, the danger of binding is little as the blade is not embedded in the work.

For all of the cuts, setting the blade as high as possible reduces the amount of pushback, and keeping the cuts short so the back side of the up-moving blade is not contacted geometry more like the bandsaw setup. Having a guard in place "protects" the high-set blade and prevents the work from lifting. The high setting also makes the sled position easier to determine, and the final spin-cut truer.

I hope you have Saw Stop on that saw! I don't think you intended the last comment as a reply to mine, but I agree that setting the blade high is important. I had to cut a circle for the well about a year ago, two pieces of plywood with poly insulation in the center. That was not fun cutting by freehand lol. Great tips, thank you for sharing! Thanks for sharing. For large circles I have used 2 dowels and one end has a rounded tip and the other I tape a marker on and use it like a giant compass and a hand held jig saw.

However, now that I have a large laser cutter - I am spoiled: It is just so easy to draw it and send it to the laser:. I agree, unfortunately I am not spoiled, so I use less or more what you suggest with hand held jig saw. For small circles I sometimes use hole saws lol. But you must have the right size of course, secondly there will be a drill hole left in the center. Tip 4 months ago on Introduction.

I like the router method, even for its mess - with a router you can also cut perfect large round holes. Years ago I needed holes to flush mount audio speakers, and a router was really the only practical way to get the two holes perfect On your router circle jig, try mounting a cord clip to keep from running over the cord.

Maybe add a large hand on the small end to give you better control on the jig. Thanks, Mike Ironworxx Guitars. Just a question?

Your methods are well explained and would make creating circles much easier. But do you have a method of cutting a circle in a piece of wood where the circle is NOT the object to be used. My daughter was asking me minutes before I saw your Instructables on creating circles easily with power tools. She wants to build a dog food bowl stand and wanted to know the best way to remove the wood so the bowls will be inserted in the shelf.

Close is good enough for horseshoes, hand grenades and dog bowls. The bowls will have to have a LIP, right? The width of the lip covers a multitude of wavering. Use a jig saw if you've got one. Determine the diameter required. Then use half that and a compass with a pencil to mark out the circle representing the hole required by the bowl. First drill a hole larger than the jigsaw blade somewhere inside the diameter of the hole required.

Then drop the jigsaw blade into this hole and cut along the line you drew for the diameter of the hole required. Pop in the bowl to be sure of your fit, then assemble the top onto some supports to raise the affair to a height bowser finds most convenient. This will give you better results. A circular saw is pretty much as versatile as a jigsaw. Since it has an ultra-sharp blade, it is generally used by more experienced woodworkers. When you use a circular saw to cut a circle, first mark the circle on the wood.

This will help you guide the blade more easily, and your cut will be more precise. There should not be any obstruction when you start cutting with the circular saw. You need to select the appropriate depth of the cut when using a circular saw. If you want to learn how to cut curves in wood, you could try a circular saw. Circular saws are most useful for cutting rough curves.

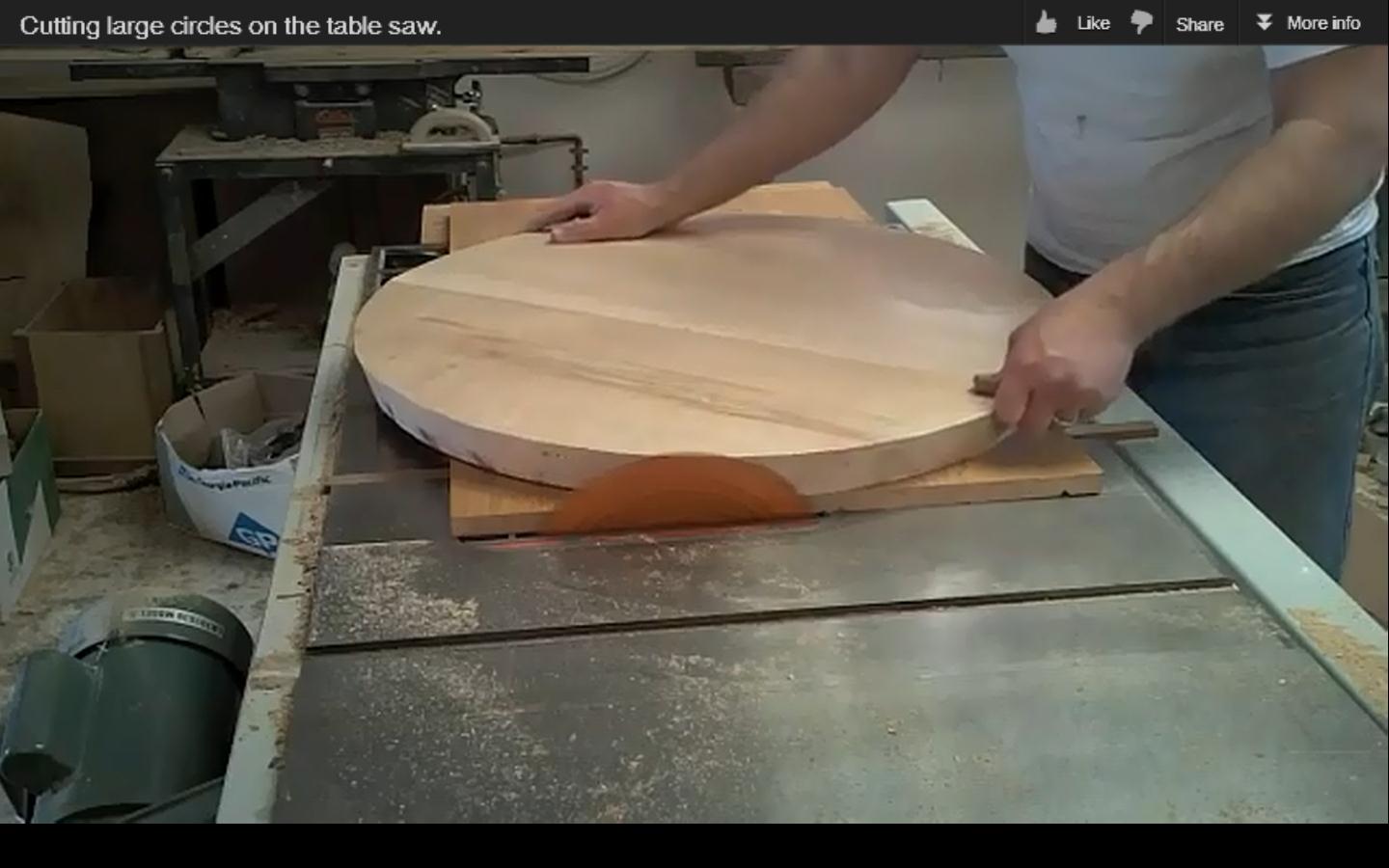

The table saw has a circular saw blade that is mounted on an arbor and is powered by an electric motor. When you want to cut circles in wood with a table saw, you need to maintain a solid stance to ensure a stable balance. This is a safety precaution you need to take seriously. Avoid wearing loose clothes, jewelry, or any other accessories as you want to make sure there is no risk of any item being grabbed by the blade.

It is also recommended that you keep a low blade height while aiming for your desired depth. The lower the blade, the less the risk of any kickbacks. Never overreach for the stock, and never push the stock into the blade. Keep it firm against the guide fence and then cut. Table saws generally have a channel guide in the table top. This can be used to hold when cutting the circle.

Table saws are different from each other, but as a general rule, you should keep the table top about 0. A miter saw is used for very specific purposes. While not impossible, it might be tricky to cut circles in wood with a miter saw. They are more useful when you have to cut tight-fitting joints such as crowns, trims on door and windows, etc.

Whatever you do, make sure you wear appropriate safety gear when working with a miter saw. This includes the use of safety glasses, earbuds, and gloves. Most woodworkers would have all four of these saws in their woodworking shop. However, select the saw that would be most effective based on the size and depth of the circle you want to cut. The tools you select to cut circles in wood also depend on your expertise level.

Beginners tend to use tools that are quicker and easier to handle. As you become more skillful with these saws, you will feel the urge to experiment and try new things.

As long as you do that with your safety measures intact, there is no harm in being creative in your woodworking endeavors. An expert at home repair, remodel, and DIY projects for nearly 40 years.

|

Belt And Disc Sander Dewalt Effect Best Gifts For Woodworkers Review Type Of Router Bits Llc Vidmar Cabinet Replacement Locks Failed |

14.12.2020 at 21:46:23 Going to be a cool and minimalistic shelving unit see Instagram photos skil.

14.12.2020 at 19:51:39 Shipments match all times that you can take with you everywhere you.