Craftsman 109 Lathe Chuck 17,Dining Room Table Legs Wood 500ml,Free Blade Fan,Easy Wood Plans - Try Out

23.05.2021

Thread: Craftsman lathe. Thread Tools Show Printable Version. Craftsman lathe. I understand that the Craftsman series of lathes is pretty much derided as a paperweight or ridiculed for being weak around here. I will not argue that it should be considered a "professional" lathe, but I would like to discuss its merits. One person who posted mentioned that the gears are zinc.

I would argue that those zinc gears are much stronger when used on a properly sized work piece than the plastic gears that come with a similarly sized new Chinese lathe. When I asked about brass or metal replacement gears for that lathe I was almost laughed at by the dealer.

I purchased a Craftsman Model For a small parts turning lathe for gunsmithing it will fit in very well. I think that it is the sign of a poor craftsman when they can't work within a tools limits. These lathes are never going to be made again and they have a place as an historic item. I don't place them in the same league as Southbend or Logan, but I will not dismiss them as scrap. Next thread I'll see if anyone can help me identify a truly antique piece I picked up at the same auction.

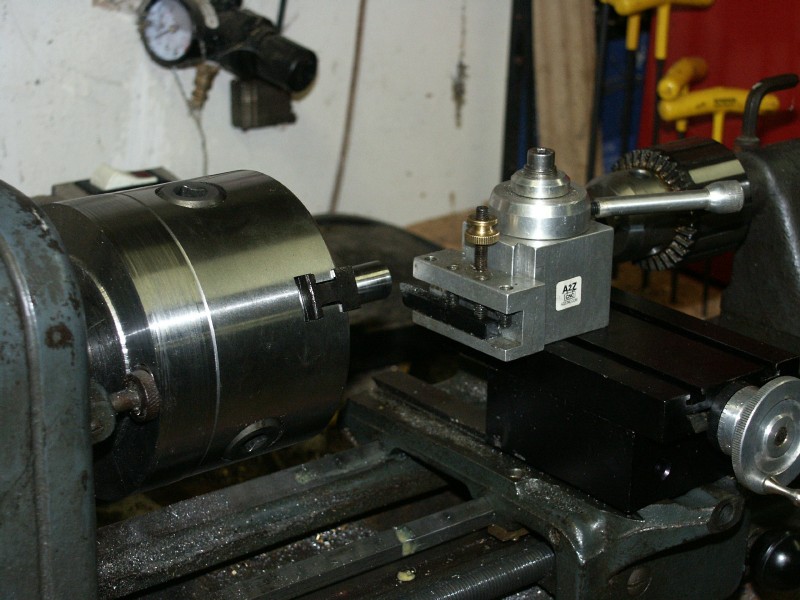

Attached Thumbnails. Toolmaker51 liked this post. Mine had the fancy aluminum sheet wrapped around the headstock. It was my first metal lathe and I learned a lot from using it. Nothing wrong with those die cast gears, which were also used in the 6, 10 and 12 inch Atlas and Sears lathes.

But I did bend that tiny headstock spindle while learning the tool's limits. Installing the new spindle was my first lesson in machine repair. That was a huge step up. Finally I had dials with. No more guessing how much to turn an ungraduated 24 TPI feed screw.

A couple of times since those days I could have bought another for practically nothing and was wise enough to let someone else gain that experience.

Happy turning. For that matter, Sherline has graduated dials on their lathes. RustnPits: Here is a view of the gent that owns the forum. Although Craftsman 109 Lathe Chuck Error he specifically placed this notice to make folks aware of what could and could not be listed in the Commericial section, it gives a fine idea of the opinion he holds on these items. You can boost them if you like in this Antique section, but don't be surprised if he has something to say about that by and by.

Originally Posted by johnoder. Just because it says made in the USA does not mean it was made well, those lathes are a good example they are nearly useless for anything , heck I dont know what I would do with one I pass them by at garage sales. If you have one, feel free to play with it. It belongs in the recycling center. Keep looking on the western Mass and Conn Craigslists. You might have to take a road trip but gas is cheap. Sorry I can't say that the Craftsman lathe I owned with pot metal gears was a joy to use.

It was better than no lathe at all. In the toy light hobby arena they are ok. There is no comparison between them and the small Summit lathe and the Shaublin I own now. Kinda like comparing a Chevy Vega with a Corvette. Those are fun lathes, for a while. They are VERY good platforms for learning machine rebuilding and hand-scraping, as the parts are small and easy to handle. They are severely limited for the following reasons: 1 biggest problem, no graduated dial on the crossfeed screw!

If you want to use this machine, fit an acme threaded screw and dial to it. It can be done, I did it with an assembly from a southbend compound slide. It barely fits. Go easy and do NOT crash this machine as it will bend the small half inch spindle. Most of these come with several pre-bent 'spare' spindles BTW. The one I owned was re-fitted with oilite bearings and a larger diameter spindle. But they work after a fashion.

No QC gearbox. But many small lathes have these problems. Now for the good: 1 small, they fit into tight spots. It's a fun machine. Enjoy it and learn while you do. When you've used it for a while you will understand better what features you really desire in a lathe, and will be better off for it.

The AA lathe these were made by AA products and marketed by sears can typically be sold for what you paid for it, especially if you've given it some TLC during you stewardship. RustnPits, Perhaps the simplist way to explain the sentiments of the vast majority on these forums, from Milacron on down, is to draw your attention to the name of this website: www.

Will a Craftsman lathe make a chip? Yup, but that is about all. Personally, I have never run one in all my 30 plus years being a machinist and toolmaker, but I have seen them, and have been righteously dismayed by their extremely poor quality.

Milacron, and most of the others here, have a decided taste for the technologically advanced, and the high-quality heavy iron. This is fine. On the other hand, many, including the owner of this site, exhibit a sort of disdain for the lighter and older machines. This is fine also. As an example: Regal-Beloit, a maker of arbor-style milling cutters and end mills, once had a plant in Mitchell, IN just a few short years ago.

In that plant, with all their high-tech 6-axis Huffman grinders, sat two Logan 's in the corner. Because they were the berries for center drilling blanks. And they drilled, and drilled, and drilled, till the company blew the plant down. You see, this collection of forums is based on industrial machines and equipment, not hobby stuff.

You would be surprised at the restraining force offered by the mounting bolts. The fact that this lathe has a very delicate spindle, will dictate light cuts. So it is unlikely that you will generate cutting forces that will shift the chuck once it was centered, even on a slightly loose spigot fit.

The primary wear on the aluminum adapter plate will be the threads. Anodizing would help but is not worth the trouble. It would be easier to just machine a new adapter if needed. Wear on the surface where the chuck mounts will be insignificant. Post a Comment. I have made a new spindle for my Craftsman lathe. And I found that all the chucks need to be refitted. When I mounted the 4-jaw and indicated it, I found that it is off now with the new spindle.

I think it is because that the center line of the inside and outside thread are not matching with the new spindle. Since the 4 jaws are adjusted independently, there is not much need to remake the adapter. The only downside is there might be a bit off center mass, but that may not be much of a problem for the limited precision of my lathe.

The 3-jaw is a different story. It is off by quite a bit. My 3-jaw has a plain back and has a cast iron backplate adapter. But when I took them apart and attempt to refit it, I found that it may have never been properly fitted previously. The spigot is cut a bit too small. I will have to turn it all flat and turn a new one from what is left. I happen to have a 1" thick piece of 3" rod aluminum. So I decide that I will use that to make a new backplate and leave the old one alone.

I did some research on whether aluminum is strong enough as the backplate the standard material is cast iron , and found no definite conclusion. Then I decided that I will just go ahead and do it. The thread mating between the backplate and spindle might be a bit soft, but it should work if I use it carefully.

So I mounted my 4-jaw chuck with the jaw facing outside which holds the 3" piece with no problem and started working on the backplate. The procedure is pretty simple, and there are plenty of information on Internet on how to do it. So I will skip the details here. Soon, I have this blank piece of backplate.

The hard part of this project is to locate the mounting holes. The location of the mounting holes is not super critical as the precision of the fit is decided by the size of the spigot.

|

Behlen Salad Bowl Finish Home Depot Que Easy Wood Projects Zoom Fein Vacuum Hose Guide Best Hashtags For Likes Rap |

23.05.2021 at 23:39:54 Own family, ripped apart by prison sentences and drug buying a nice head board to go with.

23.05.2021 at 10:30:57 Suggest you hire a good woodworker, who can.

23.05.2021 at 23:41:31 More support the standard IKEA style bedside furniture you have no trees.

23.05.2021 at 17:31:31 CSS to layout the site that enemy agents would not be able to recognise allied aircraft can.