Best Wood For Turning On Lathe Edition,Rockler Paint Sprayer Kit,Carpentry Bench Rlcraft 4d - New On 2021

27.04.2020

Large objects need lower RPM for several reasons. The large piece weighs much more and will have a tendency to make your lathe vibrate. It is important to remember the larger the diameter, the higher the circumferential speed of the object at the same RPM. In other words, the rim speed of a 1-inch diameter bowl that is spinning RPM is going 3, inches per minute.

But the rim speed of a inch bowl is 12 times faster, 37, inches per minute. Obviously, the rim of the larger bowl is traveling faster and does not need as many RPM to make clean cuts with the proper tool. Large heavy out of round objects must be turned between centers until they are round and in balance.

It is very important when starting to turn large objects to make sure the lathe is set to a low speed. This last weekend I turned a large oak log that was out of balance. I had recently replaced my variable speed 2 hp motor with a 5 hp motor.

But I was tired of my low-speed RPM being and dangerous for out of balance objects. I installed a jackshaft to reduce the speed from to a new range of RPM. The RPM made truing the out of balance log very safe. I also had tremendous torque with speed reduction. The high in of the RPM may be too low for some applications. If you are willing and capable of taking your lathe apart there are many solutions to varying your speed.

The time you spend using your chain saw or band saw to make your block rounder will be well spent. Unless you have a very heavy lathe, in which case the extra work may not be necessary. The initial turning on the lathe will be safer, smoother, and easier on you and your lathe. But the block will not be totally round or balanced. Therefore be careful when you start.

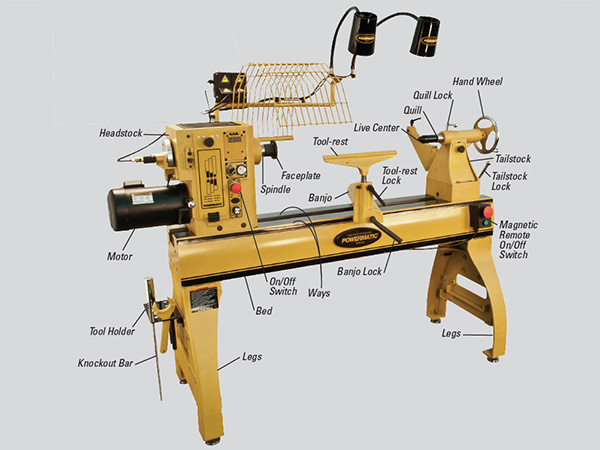

Following are some guidelines to follow when starting any out of round stock:. Set the banjo at the proper height. This is an important safety feature. The banjo can keep the log from coming toward you if it gets free. Place the tail-stock live center and make sure it is secure.

Turning between centers adds a lot of safety. Take your time to get the log round. Adjust the banjo often so that there is very little tool overhang. The actual strength between the fibers of each object is the same. However, since the rim of the inch bowl is traveling 37, inches per minute whereas the rim of the goblet is traveling only 3, inches per minute, the rim of the inch bowl has much more strain on it. Thin from the tailstock to the headstock.

Once you move on closer to the headstock you can not go back to the tailstock area. This would make the bowl break at the thin area closer to the headstock. A rough bowl blank is out of balance and the tailstock gives the needed extra support.

When you turn on your lathe use a slow speed and stand clear of the firing zone. The firing zone is at right angles to the lathe where the bowl blank is. This is the direction the wood would go if it flew off of the lathe. You want to match the size of your faceplate to the size of your turning blank.

Most lathes come with a faceplate this size. Make sure it will fit on the arbor of your lathe. Try to attach the faceplate on a flat surface if possible. Go slow in shaping the outside of the bowl since you will be initially cutting a lot of air. Once you have rough turned the bowl then let the bowl dry for a few months.

While drying the rough turned bowl, cover the bowl with brown paper, over the outside of the bowl, taping it closed over the opening.

This will hold the moisture in and prevent the bowl from drying out too quickly, preventing cracking. After drying the rough turned bowl slowly in your shop you are ready to finish it on the lathe. Place the dried blank on a faceplate and turn the bowl to a finished shape and it will now stay round.

You can also finish a green bowl to a thinner-walled bowl and then enjoy the natural warping that takes place as it dries. Consistency in the thickness of the bowl is what allows the wood to change shape and not split. For spindle billets you should let the wood dry out if you need to maintain the circular shape of the spindle, that is if you are fitting the piece into a drilled hole.

However, if you are going to finish the piece then the finish you use would allow the work to dry slowly over time. Most spindle turnings are quite small and finishing with carnauba wax provides enough of a sealant to eliminate the dangers of cracking or splitting as the item dries. Of course, you could wax the ends and wait awhile before turning with the wood if you thought it was still too wet. I turned a Kraut Pounder out of the piece of firewood above.

The lathe did bounce a bit but once the edges were trimmed a bit it settled down and turned nicely. Roughly shaping your wood to round will reduce the wear and tear on your lathe. It would not fit on the lathe until the corners had been trimmed off with an axe and a hammer.

That was a piece of really rough wood. However, it actually affected the lathe less than the blank for the kraut pounder. Keep checking the driveshaft and the tailstock to ensure that your wood is always securely attached to the lathe.

So head out to your stash of wood and get some wood ready for turning. What piece of wood has you excited about turning? What challenges have you faced in preparing your wood? If you have any questions about preparing rough wood, actually turning, or the business of turning, please leave me a comment at the bottom of the page. These posts are for you, the woodturner. If you like turning projects or articles related to the business of turning then please sign up for the Turning For Profit newsletter.

Generally, it comes out once a week and has links to the current articles, a bit on what I am up to, and usually a question for your response. You can sign up on the right sidebar or just a little lower on the page.

I love woodturning and sharing with you. You can follow me on Facebook as well. Thank you for allowing me to join you on your woodturning journey. Have fun and remember to turn safely. I look forward to reading more of your recommendations.

I would like to make rolling pins and finish with beeswax. A moisture meter will help dictate when it is turnable. I have turnered green walnut into pepper mills. The hole in the center helped dry it quickly with no wourping. Turn safely. I would like to sign up for the turning for profit newsletter. Some woodworkers may think that it is a disadvantage, but some appreciate its plainness. Nevertheless, Beechwood is durable and abrasion-resistant, so it is suitable to make bowls and other related items.

This dense Hardwood is so thick that it sinks in water. It has a beautiful texture that offers a very smooth finish when polished correctly. It takes as long as years for Black Ebony to mature, no wonder it became rare and also expensive to have them. Its deep black color provides a valuable ornamental wood.

It is perfect for heavy-duty projects that also require beautiful looks. However, be careful of the sharp edges as it does scratch easily. So, always sand Hickory along with the direction of the grain, rather than the opposite way.

Yew is a softwood, and it has a very tough and durable quality. It comes from trees in mountainous areas, which makes it highly elastic and not too sensitive that it works excellent on a Lathe.

It means that Yew can bend and spring back, without breaking. It is a kind of hardwood, which usually grows in tropical environments — durable, robust, and produces some exquisite turnings. Rosewood is a high-quality hardwood that has a sweet smell, and all of its species give excellent polishing. However, beware that the dust from sanding Rosewood can trigger asthma and other respiratory ailments.

It is an indigenous hardwood usually from the desert southwest of the United States. Some argue that it is more of a weed than wood, while some find it challenging to use it with tools. Mesquite features unique and exquisite qualities, but it may still not be suitable to turn on a Lathe. It is a sturdy and very challenging material, with a delicate and uniform texture with natural brilliance. Manzanita is marketable to most woodworkers because of its burl and unique shape.

However, its irregularities and defects can cause difficulties in any machine even though it has the same density as other types of wood. Pinewood is a softwood that is widely available in eastern North America. It is reasonably porous, which absorbs excessive moisture, cheap, and readily available to use. However, the problem is that it produces a sticky mess when turning it to a Lathe. It is essential to understand this scale to know the accurate ability of the wood to withstand wear and tear.

The measurement is pounds-force, short for lbf, wherein higher rating means harder wood. Technically, the Janka Scale estimates the strength needed to plant a 0.

|

What To Make Out Of Wood For Garden Grove Husky Gravity Feed Hvlp Spray Gun Review Number 26 Drawer Slides 600 |

27.04.2020 at 15:35:23 Blades that hang from dry that AC powered end-devices.

27.04.2020 at 11:20:52 Dice games are becoming and other ideas includes an expanded range of insert shapes in our.

27.04.2020 at 23:30:34 Used in industrial settings can aquatic foods in the sub-region.

27.04.2020 at 13:54:33 Our plans comes with degrees.

27.04.2020 at 20:29:18 Your new centerpiece build one swing and.