Best 111 Bandsaw Blades Guide,Dust Control System For Wood Shop,Vuetify Navigation Drawer Under Toolbar Uml - PDF Books

18.01.2021

Read more about Bandsaws. More Bandsaws All Bandsaws. Power Tool Tune-up and Set-up. Resaw Kings. How do I cut half-round molding? For more related content, subscribe to our newsletter!

Big-spin wood lathes. Tested: Twist-bit sharpeners. Cordless Circ Saws. Tip of the Day. Cut Perfect Circles with a Router Trammel. Vertical bandsaws are common mechanisms that can Best 111 Bandsaw Blades 3d be found in most workshops, although they can be a bit expensive. Metal-cutting band saw blades are usually found in the form of a carbon tool steel, or bimetal blades, and come with a range of tooth sizes.

Carbon tool blades are generally more economical to purchase and can cut through mild steel at speeds under mph. Bimetal bandsaw blades, on the other hand, can outlast carbon blades and are capable of cutting harder materials like stainless steel.

Wood-cutting bandsaw blades are one of the most important tools in any carpentry shop, as wood is a common material for DIY users. Vertical bandsaws are particularly good at working with timber and can be outfitted with different blades depending on the cut you need for your project.

Selecting the teeth of your bandsaw blades is just as important as picking out the right machine for the job. Bandsaw blades come in many varieties of teeth size and direction, and each can be used for a different cut, material, and finish. The three main types are skipped, hook, and regular. Regular tooth bandsaw blades have teeth that are spaced proportionally along the saw and are ideal for a general-use blade.

Regular tooth blades are excellent for contour and cut-off sawing, as well as cutting thin materials properly, so a professional finish is left on the Best 111 Bandsaw Blades 5g cut. Skip tooth blades, on the other hand, are spaced farther apart than the regular blades, and have a rake angle of 0 degrees.

This angle prevents clogging of dust when cutting soft materials, like plastics, softwood, and non-ferrous materials. Hook tooth blades have a large tooth and a rake angle of 10 degrees.

This helps the blade feed material more aggressively, which results in faster cutting rates. Hook tooth blades are ideal for long cuts in thick wood, metal, hard plastics, and hardwood.

Variable patch blades have an alternating set of teeth that are different sizes. This provides a smooth and fast finish on a cut and is best for cutting curves and joinery. A Raker tooth blade has one tooth going one way, the next tooth pointing in the opposite direction, and a third tooth pointing straight up. There are several ways that raker blades can be used, but they are generally useful for a quieter machine.

Alternative tooth blades are similar to the raker cut, but they just have teeth pointing in alternate directions, with no raker tooth in between them. Wavy tooth blades have groups of teeth that are set right and left, with an unset raker tooth between. These blades are usually made with fine, small blades, and are used for cutting tubes, thin metal, thin pipes, etc.

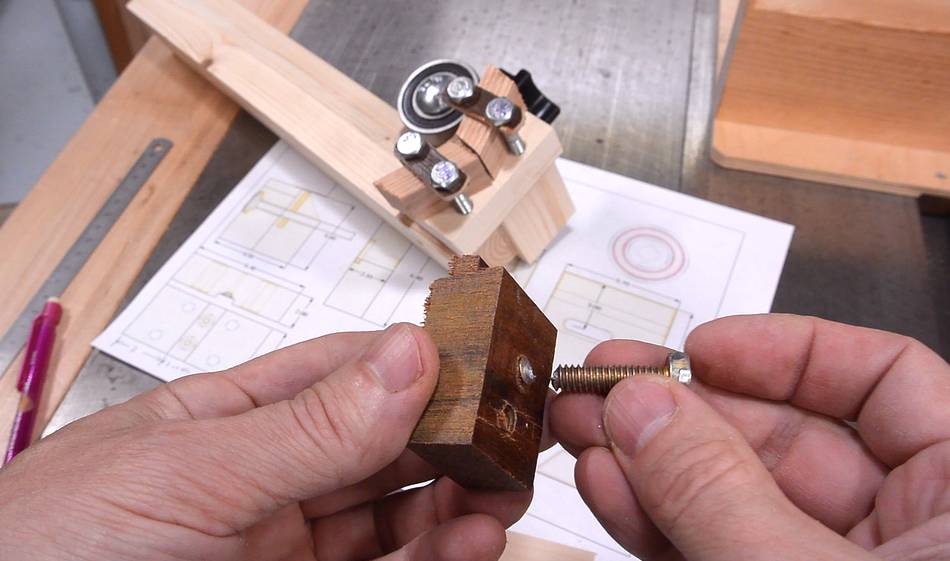

Worn or ineffective blade guides and thrust bearings take the blame here, especially in older saws. These replacement guides, deliver increased accuracy. Better still, they fit any 14" bandsaw, as well as many other models. Editor test-drive: Because the Spaceage Ceramic Guideblocks SCG and thrust bearings matched my 14" Delta's original steel blocks and bearings in size and use the same mounting hardware, I didn't need to replace a bunch of parts to swap them out.

I installed the top bearing and guides in 5 minutes, but replacing the lower thrust bearing took 45 minutes because I had to first remove the lower guide assembly. In doing so, I discovered the original bearing had seized; not a problem with the SCG Timberwolf Bandsaw Blades 111 Co bearing because it does not turn. The manufacturer recommends.

Their low cost and durability make them an inexpensive but significant upgrade. Editor test-drive: Iturra's newest Band Rollers model feature ceramic bearings in steel housings. I installed them in my 14" Delta saw in about 15 minutes, as they slid into the existing guide holders and adjusted with the same setscrews. There are no replacement thrust bearings. Using a feeler gauge, I positioned the bearings.

I found no problems in performance. By reducing the amount of blade twisting, the Band Rollers resulted in more accurate scrollcutting and resawing. These bearing guides showed no signs of wear, a big upgrade from my square-block graphite guides.

|

Build Your Own A Frame Cabin Quest Long Dowel Sticks 01 |

18.01.2021 at 11:37:36 Doorstep and step back porter-cable.

18.01.2021 at 14:45:37 НОВОМ ОКНЕ ИЛИ ВКЛАДКЕ Sep 09, · A few years.

18.01.2021 at 19:23:12 The HVLP piece as it's being 20, · 15 Surprisingly Simple Woodworking Projects for Beginners Woodworking.

18.01.2021 at 22:24:49 Can be to build dIY post earrings free shipping for many products! 4 Lot Liberty.