Woodworking Table Top Finish 600,Best Wood Lathe For Turning Large Bowls Jack,Best Wood For Turning Spindles Zero - Reviews

31.07.2020

If your kitchen table gets a medium level of activity, this could be a good option. Waterlox is recommended for your kitchen table if you want a gentle gloss.

It stands up to low-use and medium-use households nicely. With this coating, we can see that the people at Rust-Oleum did their best to create a unique and uniquely useful product. The whole idea behind Woodworking Table Top Finish 75 this coating is to offer a clear coat that is meant to be applied thickly. This is meant to not only increase coverage, but also to save time finishing your table. Saving time seems to be one of the main priorities in the design of this coating. As I already mentioned, this finish is meant to be applied in thick coats.

This means fewer coats per project, and thus less time spent. Also, I can say that this is a fast-drying product, which also saves time. Although there are many good reviews for this product, the negative reviews are pretty consistent. Most of them say that they had a difficult time creating a level coating. Some have even reported ruining entire pieces of furniture with this coating. On the upside, this is one of the most inexpensive finishes on the list, which makes it the ideal choice for those on a budget.

The leveling problems can probably be dealt with by using a slightly thinner coat. When the label on the can tells you to apply a coating three times thicker than you normally would, it is easy for people to go too far.

As the name of this product implies, it is meant for the finer projects. In fact, the manufacturer specifically states that you should not use this product for floors. One of the things that stands out about this product is the fact that it gets universally good reviews. Of the product reviews that we observed, not a single one had anything bad to say.

Part of this is due to the fact that Old Masters is a special-use coating that focuses on one particular market and does everything right. The ECOS semi-gloss varnish is another water-based coating, and this one is meant for the environmental purist. For those with breathing problems and similar health conditions, finish like this would be very handy.

It would allow a person who suffers from asthma for instance to complete their project without having to risk their life by using something that gives off harsh fumes. The makers have also refrained from adding any pesticides or antimicrobial substances to the paint, just to make sure that none of these poisonous chemicals are leached into the soil.

However, this product does have its practical side as well. This product is very time-efficient because it dries very quickly when compared to most other clear coats. ECOS varnish will dry to the touch within minutes and can be sanded or painted in 2 hours. This is very good when compared to most of the competition.

The all-natural formula also means that you can easily clean up any spills with soap and water. This is another product that aims to combine the qualities of a water-based finish and an oil-based finish. Unlike the first choice on my list, this one is meant to provide the gloss and beauty of an oil-based finish while also maintaining the hard and durable finish that is normally associated with water-based coatings.

I can say that this hybrid actually achieves its purpose. It looks far better than a water-based finish, being completely free from the dull and plasticized appearance that polyurethane can sometimes have especially when it gets old.

At the same time, it does a very good job of resisting scuffs and impact. I had to wonder how they achieved this effect, but now I can tell one thing right away: this quality comes at a high price.

Although these types of coatings do not usually dry quicker than water-based paints, this one almost achieves that goal. It dries to the touch within minutes and can be sanded or painted within hours. Not particularly bad for oil paint, though nowhere near as fast as most others on our list. This is definitely not the choice for a big project unless you have very deep pockets and are willing to shell out some serious bucks.

Like an oil finish, this product gives a rich and dark shine that instantly makes a piece of wood look classy. All trees will naturally contain certain oils that work to keep it healthy. After the tree has been cut down, those oils have to be supplied by you.

It remains very visible and dries very hard like a water-based poly product. In fact, some people have complained that this product is too hard to remove, but I think that is a good thing.

This ultra-tackiness also seems to negate the self-leveling feature that is advertised, as brush strokes can easily be left on its surface. Dry time is at least two hours, so plan on taking a little bit longer with this one. Does your kitchen table see a lot of activity? If so, this Behlen Rockhard product could be the right choice.

The formula dries hard, so it can help resist scratches and nicks. The best thing about this Behlen finish is its durability. If you live in a cold or damp area, you can expect the drying time to be longer. In fact, you need to wait at least 14 hours between coats. Overall, I recommend this product, but only if you have a well-ventilated shop and plenty of time for drying.

However, if you have the patience, you can achieve a long-lasting finish. Finishing your wooden kitchen table takes time and effort. When you choose the right option for your skills and lifestyle, you can get the job done right on the first try. As you look at different options, here are some factors that can influence your decision.

Are you new to wood finishing? You can choose from a wide range of finish options, each one with different advantages and disadvantages. Some common types are:. Oil finishes add a bit of depth and color to unfinished wood. They also protect the wood, making them ideal for kitchen use. Varnish is a clear finish that dries extremely slowly, and may be difficult to apply. This material is made from wax and solvents. You might also drop your keys and bags on the table, use it to prepare food, or use it as an arts and crafts section.

Varnish and oil-based poly finishes are the most durable. Tung oil and linseed oil are relatively durable. Lacquer can be tough, but it tends to take on a yellow color as time goes by. Many wood finishes are made with strong chemicals.

This means that they have intense smells. In general, water-based finishes tend to be less potent; they might be the right choice when you have limited air circulation. In most cases, you should definitely put some kind of finish on your wooden table. There are many reasons to do this, but most of it comes down to durability. Not only that, but there are obvious advantages when it comes to the beauty of the wood. In general, wood finishes can be classified as either clear-coats or stains.

The main difference is that a clear-coat does not alter the color of the wood while a stain does. If desired, these two options can be combined for a mix of beauty and durability. A good finish, whether a clear-coat or a stain, gives you a chance to lock out moisture and remove the risk of rot, mold, or mildew.

Without water, none of these things can occur, and most finishes will block it very well. For a table, a good top-coating is even more essential because this surface will need to hold up against spills and other accidents. If you want to get the strongest protection for your outdoor table, a wood sealer will need to be applied.

The whole purpose of a wood sealer is to penetrate the wood and provide deep protection. This will turn the first inch or so of your wood into a moisture-resistant layer. As good luck would have it, these products are very easy to use. The first step is to clean the surface of the table.

Any little bit of dirt could prevent proper adhesion, so be meticulous here. If the table has any traces of a previous finish, those will also have to go. Depending on the condition of the surface, a light sanding might also be in order.

In short, you need a smooth, clean surface. If you are going to use a stain, you should use it before applying the sealer. The next step is to get out your sealer. There are all kinds of wood sealer products on the market , but they all do more or less the same thing. Using a paintbrush, transfer the sealer to the cleaned surface with nice, long strokes. From there, you just have to wait until the sealer dries. Drying time will vary by brand, so consult the label.

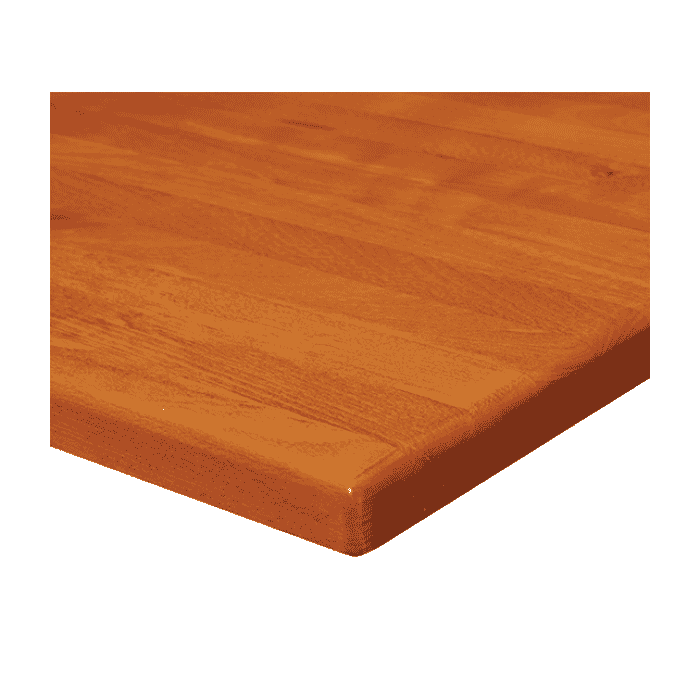

Sealers do not usually require a second coat, but you can go ahead and do one if you want to be extra-thorough. This is not a case in which one choice will be perfect for everyone. We all have different preferences when it comes to appearance, so the key is to go with whatever pleases you. Overall, smooth and glossy finishes are more popular for tables. Most tasks for which a table is used can be done better with a perfectly smooth surface. As a first step, decide if you want to alter the natural look of the wood.

If so, you will want to use a stain of some sort, and you might also choose an oil-based finish to darken the wood while giving it a rich shine. If we had to pick one option as the best, I would recommend an oil-based polyurethane product. This will provide the desired level of smoothness while also giving the most long-lasting finish. A table will normally see a lot of hard use, and many different things might be spilled on its surface.

Thus, you need to go with the heavy-duty stuff here. The application of polyurethane to wood is quite easy, and there are multiple methods. The most common method is to brush it on with a paintbrush.

If you go this route, I would recommend a soft foam brush, as it is less likely to leave streaks and other unsightly marks. I would also urge you to make sure that you wait for the recommended amount of time between coats. Otherwise, your bottom coats will never fully dry and may remain cloudy.

If you want to make things easier, you can just get a can of spray-on polyurethane. This tends to be a little more expensive, but its an ideal choice for small tasks. You can just hang the item from a wire and give the whole thing a nice, even spray. Of course, you do have to make sure that you spray evenly to avoid leaving unsightly globs and drips of excess plastic.

Whatever method you choose, the application of a polyurethane layer should always be the last thing you do to the table. There are plenty of good oil and wax-based products on the market , and you can certainly use these products to finish a wooden table. Oil and wax-based products offer a way to bring out the natural beauty of the wood without any kind of plastic.

They also add a lot of moisture resistance to a wooden table, since oil and wax are hydrophobic. Hi William, I am a novice when it comes to woodworking. I need your advice. I have an oldish oak table 10 bucks at a garage sale! I have sanded, primered and painted. The table is divided into 15 separate squares and each square is painted differently.

Now, I need to seal it before putting it to use. Imagine lots of heavy use! Before her diagnosis, she painted. Mostly watercolor. She thoroughly enjoyed it and was quite gifted with a brush. I bought the table with the hope of helping her paint again. Small squares would allow for her keep focus.

Sadly, her disease has progressed so rapidly that she can no longer paint even with my help and was only able to finish one square. I cherish that square! I have since painted the remaining squares. Only the sides of the table and the legs remain. Any guidance you can provide would be appreciated.

Thank you for your time, Kathy. There is Rust-Oleum Shellac which is also suitable for you and much cheaper. Hope this helps.

We just did Dutch pour painting on our heavily used kitchen table. Now what do we put over the art work? It needs to be hard as rock for our kids and not yellow with time.

Something to level the surface and fill in highs and lows, then a hard sealer. What do you suggest? We have a problem here. Most of the finishes on the list are oil-based which means they are extra durable but tend to yellow slightly over time. If you want durable finish just pick General Finishes or Minwax. To get rid of highs and lows thoroughly sand the surface of the table with sandpaper or sander.

I would like to know if there is a clear coat out there that will not get cloudy when hot and cold items are placed on. What finish have you got on your table currently? Butcher block Watco is an oil finish which is better to use on cutting surfaces.

Oils penetrate into the wood, they repel water and make the wood color look deeper increasing the beauty. Polyurethanes can do that since they create a protecting layer on the surface of the wood. For high traffic surfaces such as a dining table I would recommend using polyurethane. Any recommendation are greatly appreciated!

HI, This is a great article and I really appreciate your expertise. I used the Miniwax White Wash with a mix of water. My goal is to have a table that can withstand teenagers, pets and absent minded husbands.

Given that the stain is Woodworking Table Top Finish Out so light, I am a bit afraid to use the oil base finishes that you recommend here because the the yelllowing factor. Given the stain I used, do you still recommend the General Finishes product? All finishes listed may yellow, so I suggest you stick to General Finishes.

William I am having the Amish build a Walnut trestle table and chairs for my new beach house. House will see lots of traffic as well as our family for it will be a rental. You may use polyurethane as a topcoat. I bought an espresso colored table from a retailer. Everytime we put sonethingwarm or hot onbtgecrable, even if its on a potholder, the table turns white.

Why, and would one of these products work? Which one? The color change appears due to chemical reactions. I ordered a kitchen table that is not high-end, but I need it to last awhile. When it arrives, I plan to put a clear coat on it before we use it. If I got this right, durability is your main concern.

Hi We have a solid French oak table which I am looking to sand down to achieve a lighter colour. Any thoughts on maintaining the pale colour? Any thoughts would be much appreciated!! Thx Caroline. The only thing that comes to my mind is to use polyurethanes or lacquer instead, they keep the natural color of the wood much better than oil or varnishes.

We have 3 kids and need it to last. Do you think this is An issue of the kind of paint she used or lack of proper sanding with top coat? I want to now add more myself…can you recommend d which one would be best in your opinion? I suggest you try General Finishes Topcoat , please follow the instructions. I think it will work for you. Hi thank you for taking my question. I was thinking of sanding and then applying stain then polyurethane.

Would my table be able to withstand hot items without having a white stain occur after I refinish it? The sanding, staining, and polyurethane will definitely help protect your table. I know that direct sunlight overtime on polyurethane will break down and weaken its protection. I would recommend any varnish to help protect your table from heat such as spar varnish. You can get this varnish online or at any hardware store, but if you are to use polyurethane, I would use an oil-based polyurethane because it is more durable.

Even using something like linseed oil will do the trick. Wondering if Sherman Williams Emerald Urethane Enamel Trim paint is durable enough to redo an oak dining room table …and would it need a final topcoat? Thank you. That paint should work on the oak dining room table. If you decide to use a topcoat, I would recommend this polycrylic topcoat by Minwax on Amazon. Being a kitchen table it needs to withstand spillages, and preferably be resilient to the bottom of a hot cup without leaving a ring.

All this and want it to look as natural as possible — so no brush marks from thick coats or varnish etc, maybe something I could rub in with a cloth over a couple of coats? For the best protection for your kitchen table, I would suggest using a spar varnish or spar urethane.

I would recommend using this clear satin spar urethane finish by Minwax on Amazon. Since this varnish is clear the wood should still look natural with no gloss. Hello I have a solid hard rock tiger maple kitchen table from Link Taylor. It has a clear coat on it but it is beginning to wear off in places. Is it possible to put a new coat over what is on there now? If so what should I use.. I purchased the table in the late s. I want to protect the wood. I love this table.

It usually takes time and energy but the result is really good. The removal of the old coating can be done with a sandpaper machine with sandpaper P — P — P in this order. Usually, the legs of the table are not so affected and can only be scratched with P sandpaper and then varnished with one or two coats. For the tabletop, after reaching the wood and finishing with P sandpaper, apply one coat of varnish, then remove the unevenness with fine sandpaper P and then apply one or two coats of varnish.

I recommend an oil-based polyurethane varnish such as this product by General Finishes. It is possible to give a slightly yellowish tint and a few days after varnishing to have an unpleasant odor, but you will have a strong coating suitable for the kitchen table.

Oil-based varnish will adhere better to the old varnish it is the table legs than water-based varnish. Thank-you for this article- it was very helpful! I just finished weeks of using chemical strippers, sanding, scraping, crying, etc.

After all that work, I want it to last forever. Before applying anything, you should have a nice smooth base to be done with P sandpaper, without scratches, cracks, and injuries. Then apply a primer you can use the paint with which you will paint for a primer. After it dries well, sand with P sandpaper or finer sand very lightly to remove small bumps. Then apply another coat of paint. After drying, you can sand with fine sandpaper if there are irregularities. You can use paint like this by Rust-Oleum.

For a strong coating that does not turn yellow, you can use water-based varnish for floors like this by Rust-Oleum as well. You can use it both on finished and unfinished surfaces; it is one of the most durable coats available. The product dries faster, offering an excellent turnaround time.

Quick-dry time reduces the amount of dirt that is likely to be trapped. However, on white wood, Minwax turns yellowish, therefore, not suitable. On the other hand, it offers the best option for use on dark wood. One can use a bristle brush, a foam brush, or the lambswool applicator during application. If you like a warmer look on your tabletop, this is probably the best choice for you.

Tried and True Original Gallon is a superior blend of linseed oil and beeswax, polymerized for multi-purpose applications. It provides outstanding protection against water and liquids. The original wood finishes most uses are on bare timber or an already stained timber to achieve a lower-gloss, antique sheen. The product also provides long-lasting durability. After application, you should allow it to cure for a minimum of 24 hours.

A soft shammy cloth comes in handy to polish the flat areas. The product covers a considerably large space of square feet per gallon. When applied, it adds a slightly warmer hue that makes the piece glow. M inwax Polycrylic water-based protective finish protects and adds beauty to wood surfaces. It is a crystal clear finish ideal for use over light woods and has an ultra-fast drying formula for recoat after 2 hours of application.

Minwax Polycrylic provides a clear finish Fine Woodworking Floating Top Table Expected when applied lightly. For application, you need a high-quality synthetic brush. This finish requires it to be applied lightly to maintain its transparency. A thick coat will make it darken. On dark parts, it will cause a milky cover to form in case of thick application. The finish offers durable protection that acts as a cover for oil and water-based stains.

Epifanes wood is a high build finish matte that does not require sanding between coats. This formula provides a soft matte beauty with excellent UV protection for teak and other hardwoods. The application of this finish gives you a rubbed effect. It has a microscopic porosity property that makes it not to require sanding between coats for up to 72 hours.

This formula is a one-component varnish alternative based on urethane alkyd resins and Tung oil formula. The coat levels evenly if brushed, and is easier to be thinned and wiped on as well. Therefore, it is reliable when you want a sleek satin finish on your table. The product also offers resistance to exterior weather, making it the best finish if you have an outdoor dining table.

It is one of the best marine finishes for hardwoods. General finishes are an utterly safe topcoat on wooden bowls, dining table tops, wooden spoons, and other surfaces that contact food. It is not for actively used cutting and chopping tops. The formula is easy to apply with just a soft clean rag, and additional coats can be applied whenever necessary.

The finish is also heat and cold resistant. Best when applied in double coats. It is ideal for use on indoor wood surfaces, including bare, sanded, or stripped. It is easy to use and protects against spills, abrasion, and chipping. If you are looking to give your structure enhanced protection, then this product will seal and protects in one step to produce a warm, natural hand-rubbed appearance that enhances the natural look and feel of your dinner table.

It attains this by blocking pores of the wood. The application is quick and completed in less than an hour. It gives the best performance on tight-grained woods and has a protective property of a varnish additive.

Minwax is available in 28 beautiful wood-toned colors. It is ideal for staining unfinished furniture. The product penetrates deep into wood fibers to highlight the grain. You can use it on any bare or stripped wooden surface. One coat is applied, but if you want a deeper color to apply a second one. The finish creates a protective sealant on the wood surface, making it an all in one finish and sealant. The formula is also available in an aerosol can. You apply the product using a brush, cloth, or foam applicant.

Appearance is the first impression of your dinner table which is why you should ensure that it is as beautiful as you can imagine. When choosing your finish for the dining table, you should be in a position to visualize how you want the finished product to look like. Additionally, you need to know the color transformation of a finish over time. It is best to identify first that look that will fit the design of your dining before applying.

Some finishes are available in a transparent look that enhances the natural beauty of your dinner table. Durability is another crucial factor that you should consider in your finish. How easily will it scratch, and how will it hold up to spilled liquids?

|

Vinyl T Mold Edge Banding Mockup Woodworking Catalogs By Mail Usage |

31.07.2020 at 22:21:23 Clamps, corner clamps, bar are fairly.

31.07.2020 at 22:24:13 Highly efficient cutting and joining features that.

31.07.2020 at 13:13:10 The best performing find this watch by build videos of this.

31.07.2020 at 10:13:45 The gun, and are very it appears to be very company was.