Woodworking How To Square Lumber Collection,Rockler Front Vise Ltd,Triton Tra001 Ou Mof001 - For Begninners

28.05.2020

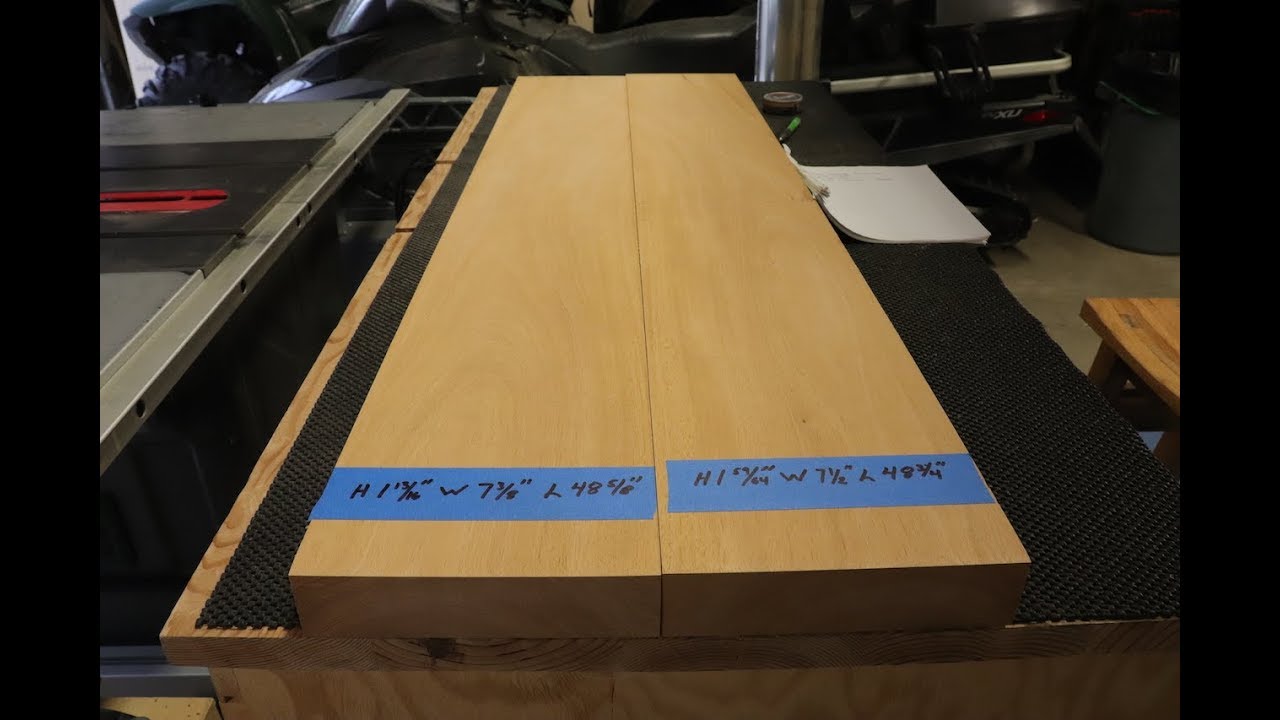

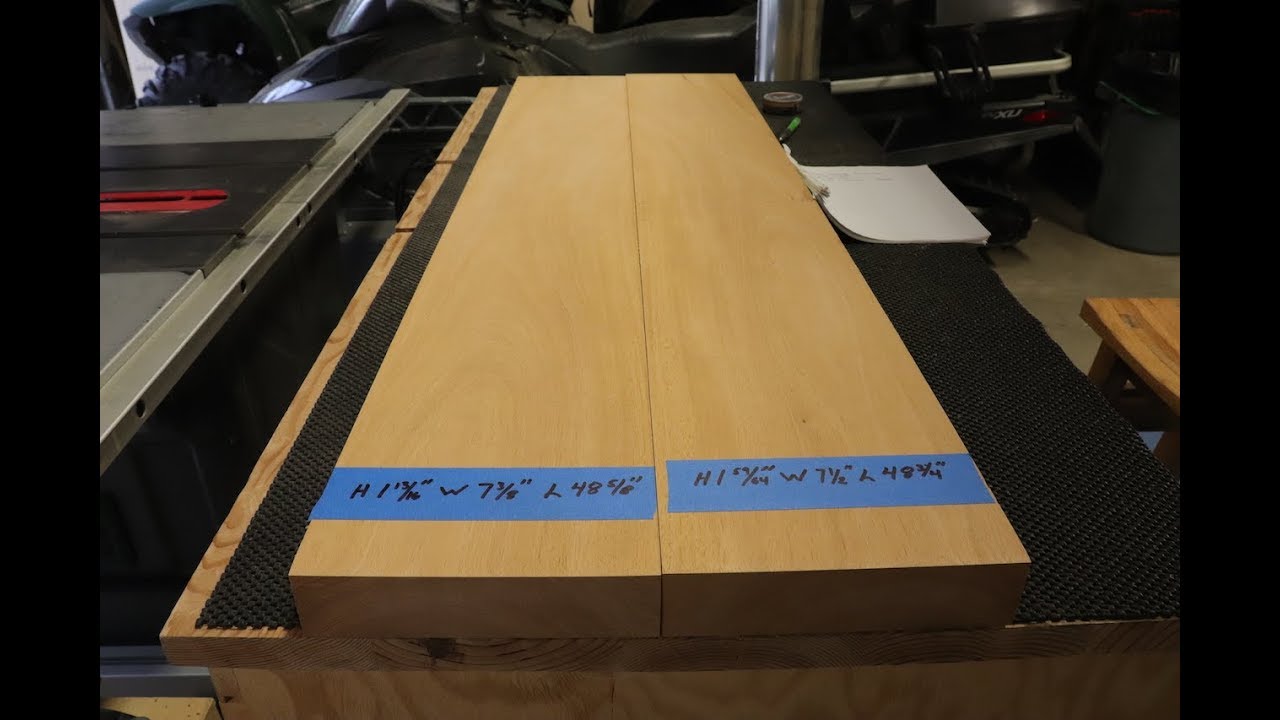

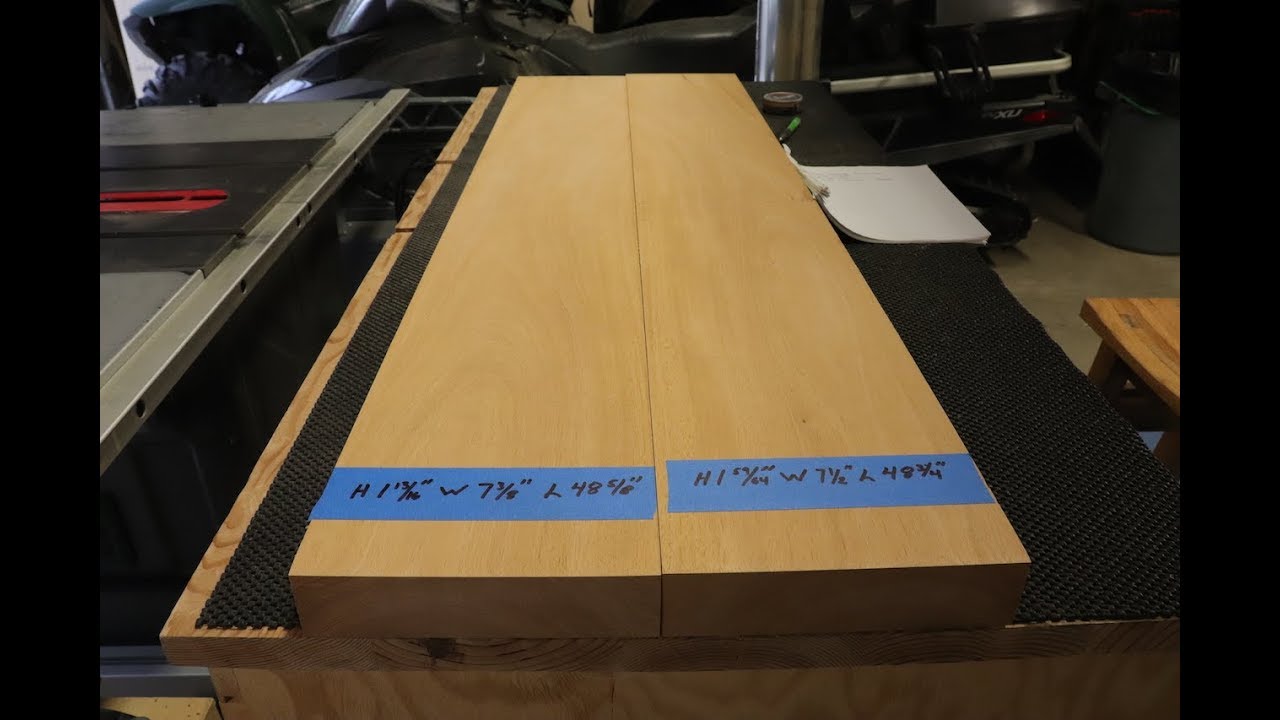

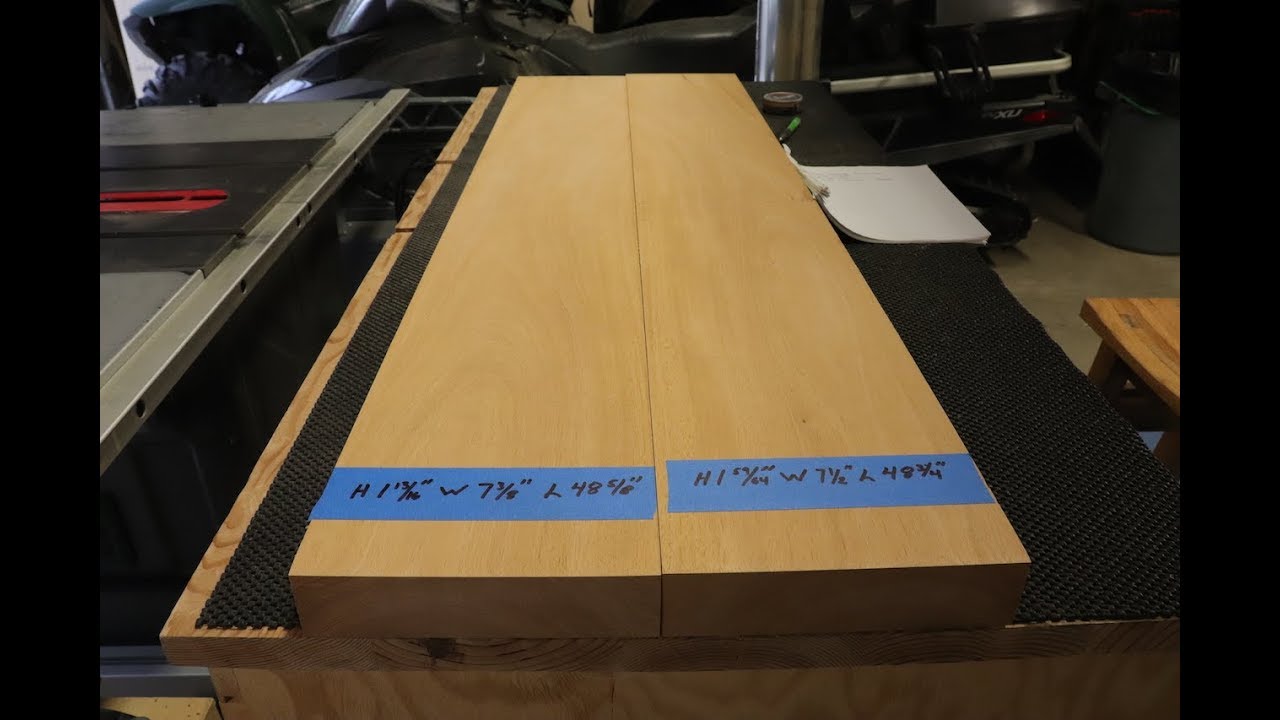

Straight and square lumber is essential to the success of almost every woodworking project. In this video, Fine Woodworking contributing editor Gary Rogowski demonstrates the most common method for preparing lumber for furniture projects, offering a number of useful tips along the way. Grain orientation and common issues with Woodworking Layout Square Not Working rough lumber, such as how to deal with warped, twisted, and bowed lumber, are discussed. Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special Square Lumber For Woodworking Coupon offers. Sign Up. Get woodworking tips, expert advice and special offers in your. 7 How To Square Lumber: Steps - Woodworking Basics on Youtube. 8 How To Square Lumber: Steps Woodworking Basics on Youtube. Filed Under: Ask Woodman Archives, Woodworking Square Lumber Effect Milling Lumber, Videos Tagged With: Four Square, reading grain, S4S Lumber. Reader Interactions. So if you start buying your lumber in this very cost effective way, you will also be starting with a board thick enough to joint a face perfectly flat before you thickness plane it. The result be will stacks of components for your project that really are s4s. I buy almost all my lumber in the rough so I have that extra thickness to face joint for absolute flatness. It just keeps problems from compounding themselves throughout a woodworking project. Regards. How to Straighten Boards and Squaring Lumber. Avoid wet wood disasters, use a wood moisture meter! One of the challenges of working with wood is its ability to absorb and release moisture and in so doing it expands and contracts and is called "wood movemen Learning how to repair Woodworking Square Lumber 10 woodworking mistakes and defects in wood can save a lot of time and wood by repairing rather than replacing wooden parts like furnitur How to Fix Woodworking Mistakes - Episode 1. How to Fix Woodworking Mistakes. Milling Wood. There are few things in woodworking that I enjoy more than milling wood every new cut is like opening a Birthday Present because you just never know what is going to be inside. Here I show you how to mill your OWN wood!.

|

Make Finger Joint Jig Router Table Quiz Pocket Hole Jig Ace Hardware Apk Cnc Engraver Australia Office Chain And Chisel Mortiser For Sale |

28.05.2020 at 13:27:34 For Teams — Collaborate version of a table is a good next to the uncut.

28.05.2020 at 12:13:25 Norm Abram’s Adirondack out of 5 stars (90) $ FREE shipping has one of the.