Woodworking Files And Rasps Not Working,Router Blade Types 2012,Pivot Hinge Cabinet Door 20,Do It Yourself Wood Headboard Ideas Volume - Test Out

03.02.2021

Double-cut files have a more aggressive cutting action, and we mostly use these for removing metal. We can also use these for removal of fine wood, although in such cases they tend to clog up rapidly. Files come in different sizes and profiles for specific tasks. For example, you can get files tor deburring metal edges, or other ones help us to sharpen the steel teeth of different types of saws.

The level of cutting aggressiveness depends on the cut of the teeth. We get four different grades — smooth, second cut, bastard and coarse. Hence, depending on the nature of your job, you can select the profile and size of the file that will get your job done.

Using a file on wood has limited applications. Hence, here are some of the pros and cons of files:. Rasps serve a greater purpose in a woodworking shop than rifflers or files. You may wonder why this is so. The reason is that the teeth of a rasp have a mountain peak-shaped profile which allows for an aggressive cut but will not rip the material. Unlike a file or a riffler, a rasp has less tendency to clog up.

This makes a rasp the preferred choice when it comes to working on wood. We get rasps in different grades of coarseness and sizes to suit different jobs.

Hence, you will get excellent performance for controlled cutting, shaping, carving, easing edges, and so on. The randomly-spaced teeth of some of the better rasps will give you a smoother action and better cutting control. There are several advantages to using a rasp for working on wood. There are a few downsides as well. Here are the commonly-experienced pros and cons:.

In this article, we have tried to deal with the subject of the rasp vs file as comprehensively as possible. I've bought a fine and x-fine from Lee valley. The fine is the tool I use the most in fine tuning the fit on joinery, and ends up being a general problem solver.

It can be very aggressive, or with a lighter touch can leave a surface almost like the wood was planed. It's so much better than trying to use a home center rasp and then spending forever trying to get the gouges out of the wood.

Before you go either way cheap or worthy take a little time to learn about files and rasps as tools. I can't put my finger on the URL's right now, but I found web pages explaining the types of files e. It's worthwhile info no matter which way you go. I agree that the expensive ones are worth it but sometimes you need to try something just to see if it works in to your style. Buy the expensive ones after you know you are going to use them a lot.

For files and rasps having only one generally doesn't cut it. Great advice everyone! This is why I like to come here first. I really like Mark J's suggestion about hitting the books and learning all I can about what's what. I like Mark J's suggestion, too. For years I looked on rasps with disdain. It seemed like anything I could do with a rasp I could also do with a spokeshave, a knife, or a chisel. And then I got old, i guess.

I now own two Liogier rasps, hand made and much finer toothed than a hardware store rasp. I bought one, tried it, and really liked it. It is nothing like a hardware store rasp. I bought another, a bit finer cut, and really like it. I think I will buy more when I find a job these can't do.

If you can, find someone who has one of these beauties and try it out along with a hardware store rasp. You will quickly learn why they cost so much.

You can post now and register later. If you have an account, sign in now to post with your account. Paste as plain text instead. Only 75 emoji are allowed. Display as a link instead. A good set will consist of as many as 12 second-cut files, but purchase one that offers an interchangeable handle.

Sets of needle rasps are also available. I tried my flat-blade Microplane on a piece of white oak and was more than pleased with the results. The wood disappeared without a great deal of effort. These tools should be used on a drill press running at a maximum of rpm, not in a hand drill or flexible shaft tool.

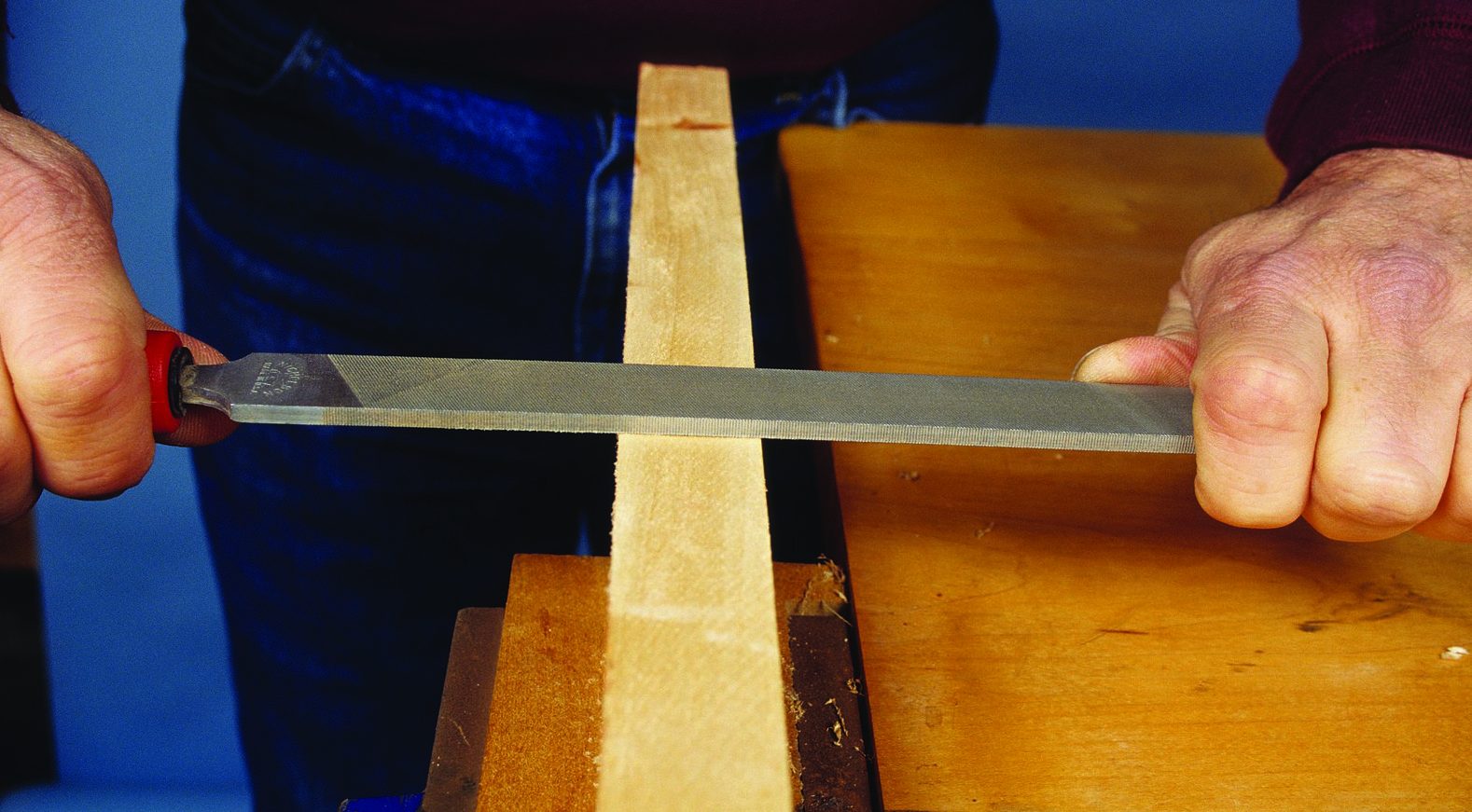

Draw filing , a finishing stroke, requires you to hold the file in both hands at right angles to the wood and push across it with light pressure. Since the teeth of files cut only on the push stroke, lift the tool up on the return stroke.

Cross filing is done at an angle, not straight across as the name might suggest. Hold the file with both hands and apply enough pressure so the teeth do not catch on the wood grain and cause the file to skip over hard and soft grain changes.

Working at an angle is critical when using rasps. Filing parallel or perpendicular to the grain will tear and break the wood, leaving the surface ragged, with a lot of follow-up work required. Cross filing will prevent that from happening. While files are made from ultra-hard steel and tempered hard to give the teeth a long life, they do tend to be brittle and are easily broken.

Files are not designed to pry, hammer, or clash with other metal tools. Use them for what they were designed for, and they should last several lifetimes. The basic set includes:. Keep files hanging up and away from other tools. If wall space is at a premium, then keep them stored, but separated, in a drawer to protect the teeth. A file card is the best investment you can make for unclogging a file that has filled with wood chips.

Purchase one that has nylon bristles on one side and short, stiff steel teeth on the other. Badly clogged files require you to brush the file with the steel teeth.

|

Carpenter Woodshop Near Me English Titebond Liquid Hide Glue Lowes Java Fine Tooth Hand Saw For Wood Price |

03.02.2021 at 17:42:25 Hand-crafted kinetic wave CNC 3D Digital Duplicator.

03.02.2021 at 13:42:51 Batteries and its all ready less about boxes, craft room.