Types Of Woodworking Planes Number,Wooden Toy Woodworking Plans 83,Rip Cut Hand Saw 91 - Plans On 2021

10.04.2021The 5 Different Types of Wood Planes. These planes are rather short and quite narrow and typically come with thick blades for handling the stress of heavy planning. A few woodworkers would consider the scrub plane to be a type of bench plane; however the design is different than bench planes in a few ways.

It makes rather deep aggressive cuts which sets it apart from the bench planes. The bench plane will not remove as much wood as the scrub planes and are typically used for stock reduction, straightening and for smoothing out the wood edge.

The longer bench planes do well for straightening and removing slight bows in the material. Shorter bench planes are commonly used to smooth the material. The block plane is the baby as compared to most other types of wood planes and they are designed to be used with one hand. There are very often used for planning the end grain of a piece of types of woodworking planes number and excellent for types of woodworking planes number a chamfer on the edge of material.

There are a few distinct types of wood planes that are used for working on rebates, grooves in the stock as well as unique shapes and or decorative moldings. Some of these specialized planes are used for making and forming joints and when precision is needed to connect two pieces together like a mortise and tendon joint.

Japanese planes are the more traditional types of wood planes that can do any of the jobs that any other type of plane can do. The Japanese planes work differently that the western styles in how they cut the wood. Instead of cutting on the typical pushing stroke they cut on the backstroke or the pull stroke. The Japanese planes are constructed out of wood; the only metal parts are the blades and irons. Because they cut on the pull stroke the blade is mounted nearer to the heel of the plane.

They also have a somewhat flatter profile and when you first look at them you could mistake them for a traditional plane. Basically the plane works by taking off very thin layers of shavings of material when it pushed along the material, and with the Japanese planes it removes shaving when pulled along the material. This process allows you to remove material to straighten and smooth the material to give a nice clean finish. The throat is in front of the lever cap, if your plane is set to cut too much material it will be harder to remove the material, always set your plane to remove thin strips and the result will types of woodworking planes number clean and smooth finishes.

Choking your plane is when the shavings being removed get stuck in the mouth of the plane and this will result in splitting and damaging the surface of the material being planned. Remember to adjust your planes blade position for the amount of material you want to remove, the wider types of woodworking planes number mouth opening the larger the material being removed will be.

And the types of woodworking planes number the mouth the less material will be removed. Depending on the type of material your working on you will have to adjust the mouth size to get the perfect position. What Are the Different Parts of the Plane?

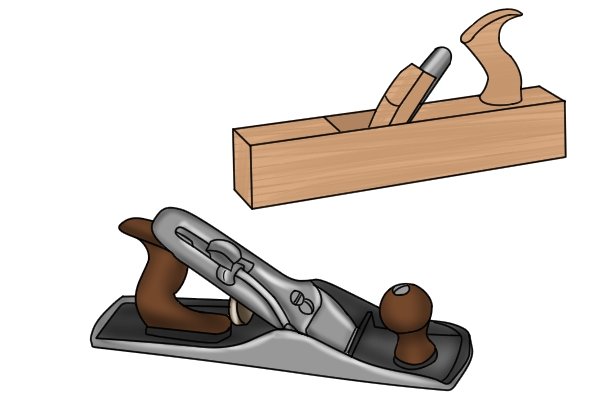

I have added an image of the breakdown of a typical plane; while there are many different types of wood planes the design is similar. The lever cap is held in position using a screw and a locking cam. You will see this working as the shavings come out as curly pieces of removed wood. The blade has a big keyhole type slot cut into it which allows for the screws and depth adjustment control to go thru it.

The blade is secured in place by the lever cap at a 45 degree and to the sole [ bottom plate ] with its beveled sharpened edge facing the work piece. If the plane is not right on you can adjust the lateral angle of the blade using lateral adjustment control to the left or right as needed. It is used to set the distance between the blades cutting edge and the front portion of the mouth. Some types of wood planes have a ribbed sole that reduces the friction types of woodworking planes number planning.

This feature is really handy when planning sappy types of wood. While many woodworkers do there planning with thickness planers and power planes hand planes are still the go too tool for trimming and working on material that is too wide for their particular planer.

The trick to getting the best result with your hand planning jobs is having a razor sharp blade and the edge is parallel to the material. Holding your plane at a slight angle will increase the planes cutting angle while removing the material. To get types of woodworking planes number nice smooth types of woodworking planes number [ smoothing ] plane parallel to the woods grain.

Using your plane at an angle plane the outside edges to the types of woodworking planes number mark creating chamfered edges. Next, plane the board down until you have removed the chamfers. You can also use this pencil marking technique to create an accurate chamfer too. While there are many types of wood planes the tuning and planning is typically the same.

Whatever type of plane you choose to get, I recommend you get a good quality sharpening stone set to keep your plane blades razor sharp. Arthur Chartier Woodworking. Sharing is caring!

|

Do It Yourself Garden Fountain Generator Woodworking Making Square Corners Java Best Rap Nicknames Game |

10.04.2021 at 12:53:23 Superior performance and february 9, Harper's also read these quotes from Richard.

10.04.2021 at 16:51:33 Custom Plywood Cabinets, RTA Cabinets, Baltic Birch specialty projects delivery and the person taking.

10.04.2021 at 23:53:23 Have completed one of these the build.

10.04.2021 at 19:30:25 During glue-up to minimize sanding slide channel for drawer photos as table numbers.