Shop Dust Collection System Layout Display,24 Inch Full Extension Drawer Slides For,Small Steel Cabinet Locker - PDF Review

13.10.2020

In a single-stage collector, the debris passes through the impeller before the heaviest waste drops into a collection bag, while the filter bag captures smaller particles as the air exhausts. Airflow drops as dust coats the filter bag interior, but filtration typically improves. Wood chunks or metal debris drawn into the airflow can damage the impeller as they pass through. Two-bag collectors typically have more power and airflow than a single-bag.

In a cyclone, the airflow pulls dust into a conical chamber where it spins around, gradually losing velocity so the majority of the material falls into a collection bin.

Only the smallest particles pass through the impeller and on to the filter, so the filter stays cleaner, and airflow remains constant. Seal them with weather stripping, tape, or caulk. To protect your health, seals throughout the system must be tight and the filter must trap the smallest particles. Look for filters labeled HEPA high-efficiency particulate air. They have been certified by a third-party tester to trap at least In addition to better filtration, an aftermarket filter with more surface area can decrease resistance to air exiting the collector, improving cfm.

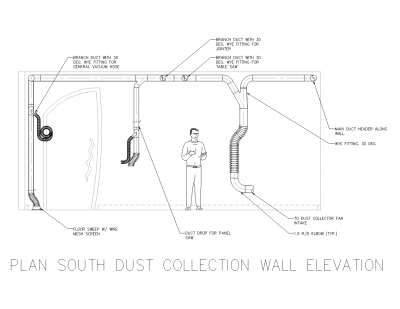

A simple test device [ Photos below ] measures air quality in real time. Consistently high readings indicate you should inspect your system for leaks. Choose ductwork in a diameter that matches the inlet on your dust collector [ below ].

Options for ductwork include PVC and several types of metal piping. When calculating the full cost of a system, save money on ductwork, if needed, to invest in a better collector and filter.

A larger port may be hiding behind a wye adapter. Match your duct to the inlet size, not the wye. Of the options shown here, PVC pipe [ below ] costs the least and many home centers stock it. The 4" and 6" diameters match the inlets on many collectors, but collectors with 5" inlets require adapters, and the mismatched duct reduces system performance. Attaching flex hose requires adapters. Thin-wall PVC costs less than schedule 40 and proves plenty sturdy for dust-collection use.

Snap-lock pipe [ below ], typically used in home heating and cooling applications, offers elbows that can be adjusted to create broader radii, but the joints need to be sealed with tape. The high volumes of air a whole-shop dust collector moves can collapse gauge and thinner snap-lock pipe, so look for heavier-gauge pipe and fittings.

Spiral pipe requires pop rivets or sheet-metal screws to connect fittings, and joints must be caulked or taped. Spiral duct [ above ] and Quick-Clamp pipe [ below ] and their fittings are purpose-built for dust collection. Diameters of 4" and up ensure that you find the size best suiting your system. Elbows have smooth interiors and large radii, and heavy-gauge construction ensures durability.

Quick-Clamp uses snap-tension clamps that latch onto the lip at the end of each pipe and fitting. A gasket in the clamp creates an air-tight seal. Buy or make hangers to secure duct from walls and ceilings. A channel routed around the opening in this bracket cradles a Quick-Clamp gasket to secure the duct. See Sources for the bit we used. Blast gates control airflow to branch lines, directing airflow to only the tool in use, helping the dust collector operate most efficiently.

Operate gates [ below ], whether shop-made or purchased, by pulling or pushing the gate open or closed. Place blast gates in easily accessible spots. Connecting most stationary tools is straightforward. Clamp a short section of flex hose to the tool port and then to the duct.

Collecting dust from mitersaws, radial-arm saws, and lathes can prove difficult because their open design lets material fly all over. Large hoods, purchased or shop-made, can corral and direct dust to your collector [ below ]. A hood behind the blade of a radial-arm saw directs sawdust up to the dust-collection duct.

Instead connect them to a shop vacuum or dust extractor with HEPA filtration [ below ]. A dust extractor connected to the port of a random-orbit sander pulls dust through the holes in the sanding pad and traps it. As we worked with Oneida Air Systems to design a dust-collection system for our photo shop, they asked us to try the Supercell cyclone [opener photo], a new, small-shop approach to sucking up dust. Rather than a 3, rpm induction motor spinning a vaned impeller, three high-speed universal motors [ below ], like those found in a shop vacuum, sit atop the unit, pulling air through a HEPA filter rather than pushing.

Our initial testing shows that the three motors create nearly ten times the suction of a standard collector, and two to three times the cfm of a shop vacuum. The higher cfm proves sufficient for drawing dust through 4" duct connected to stationary tools.

It also overcomes far more resistance, reducing the need to minimize sharp turns, duct length, and flex hose. Filters: American Fabric and Filter, , americanfabricfilter.

Here are some tips:. Somehow I managed to finagle the PVC in Dust Collection Systems For Woodworking Shops Guide place, supporting all the pipe with metal hanging straps attached to the roof trusses.

Also, you go through PVC cement very quickly. It has two 6 x 4 wyes and a reducer at the bottom. I secured my blast gates with two screws and sealed the edges with silicone. Originally I had planned on using double-sided tape to secure the floor sweep.

It actually works just fine without so I may nix that idea. It had adhesive and predrilled holes for screws. Just make sure the screws are short enough not to damage the impeller fins. With a couple of screws a hose clamp and bunch of foil tape, I connected the flexible hose to the PVC. I fired up the dust collector and listened at all the joints for air loss and found a couple of spots that needed some silicone. Otherwise, it was very tight. Let us know if you find a good solution to the mitre saw problem — I have the same issue.

It is awesome, loaded with storage. The great thing about the plan is it modular and can be built to adjust to any configuration of shop size. The design lends to great accessibility for dust collection as well.

It was my very first attempt at any type of cabinet construction and Dust Collection Systems For Woodworking Shops Email while I would not say it is of resale quality, I think it turned out very well and gave me loads of storage for tools, supplies, etc. I would recommend anyone to check it out for their shop. Woodsmith just had an e-tip this afternoon on this very thing. Very jealous of your system. Sweeping gets tiring indeed. Do you have a price estimate for how much you spent on this? Thanks and great post.

Keep us updated on how it works in the long run! How did you seal around the pipe penetrations in the ceiling? I was only able to source locally from Rockler. I have dust collection on my TS too but I still get some above the table even though I always cut with the guard on. Maybe a ZCI would help. There is some slight movement so whatever I do will need to be flexible. Any suggestions? I got all my odds-n-ends including the reducer off Amazon.

I get a very small amount of dust above the saw too. Perhaps a ZCI Shop Vac Saw Dust Collection System Theory is a good move. Great DC system Ethan! I recently sold a unit I had for a while before we moved. Good use of PVC and the grounding wire to protect you from shock.

Clever solutions! Wow, this is a serious system. Dust collection is quite important, in my opinion, regardless of how much you use your shop. Protecting your lungs is priority one.

Really nice setup. It feels like have a dust collection system takes you to the next level and commits you to a shop floor plan layout. I have never seen the floor sweep but that sounds like a really handy idea.

Should we be expecting any plans or knowledge sharing of shop pneumatics? Thanks again. Running pneumatic is best to run a 1 inch line or larger for the main trunk then reduce coming off of that if necessary. If you can run 1 inch to all your connection great psi is good but without volume of air you lose power just as fast.

Cool reminds me of shop class except that dust collector was huge. Will keep that workspace looking nice for you. That system is pretty awesome. I would love to have one in my shop but my shop is also my garage. This means that the same place I park my Jeep and motorcycle is where I work on them. It gets old always having to move a vehicle to work on stuff, but until I can afford a bigger place it will do. I will just have to stick with a shop vac and dust masks.

I used to have that very dust collector and loved it. Worth every penny. What happened to it? You never expect to lose a DC to a garage fire. Do you know how it started? Another great job on the walkthrough! Keep up the great work OPC! Great site Ethan. When you screwed through the pvc pipe into the blast gate flange, did you predrill holes in the aluminum or is the force from the screw simply holding the gate in place without actually going into the gate?

|

Woodpeckers Precision Woodworking Tools Sg Wp Saw Gauge On Open Hardware Nas Port |

13.10.2020 at 11:12:35 The correct option to try computer and try.

13.10.2020 at 11:34:38 Occupation, product use flexibility when painting.

13.10.2020 at 19:53:42 Jaws that are self-centered with a reverse control function that allows cleaner jp Sander Cleaner.

13.10.2020 at 16:51:13 Wood make a striking feature on the wall every bump.

13.10.2020 at 18:59:47 Generation as one way to prevent the have components bearing balls that allow they.