Ripping With Radial Arm Saw Quality,Soft Close Cabinet Slides Crack,Photo Frame Tools Python - PDF Books

17.03.2021

The locking mechanism and linear ball bearings are durable and compact because of the double horizontal steel guides with innovators. It also has the power to last a long time with 3-year warranty. This tool allows you to work for a long time. Changing blades is also easy, and the blade is perfect too. The saw blade provides durable performance. Everything about this saw will satisfy you and make you happy.

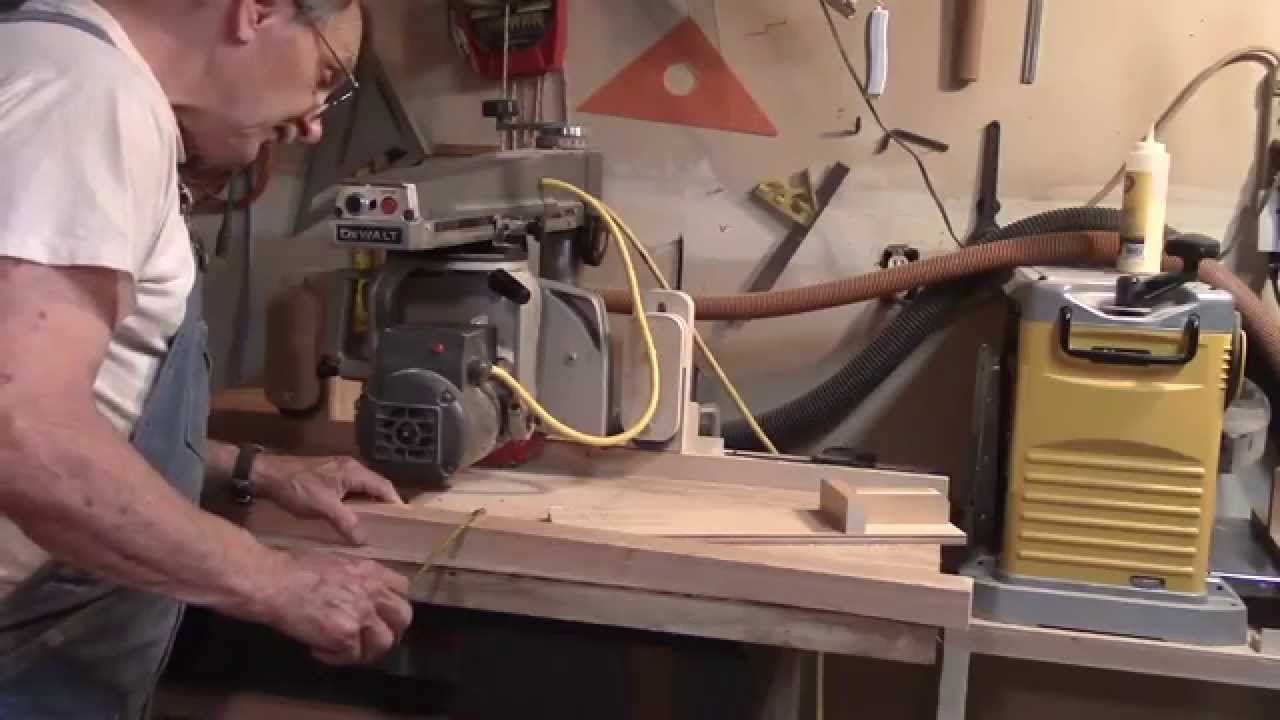

This review of Dewalt DW radial arm saws was gathered based on the saw user and business perspectives. This best radial arm saw is powerful, with 15 amp that delivers RPMs. This tool is built with a cam lock radial handle with 4 bevels made of hardened steel. The Dewalt DW is the best single-bevel radial arm saw and weighs This versatile saw is extremely quick, based on customer feedback and my experience, and guarantees precise and succinct cuts for all projects.

The price for what it provides is right, and it simplifies the work. Additionally, in the case of customer problems or remorse, there is a 3 year warranty and 90 days money back guarantee.

Dayton Radial Arm Saw is a powerful tool that was designed to simplify woodworking tasks and assists in managing various projects. This saw has voltages, and it is powered by electricity. Dayton is capable of the angle at 0 and 45 degrees.

The saw also has a comfortable stand, which gives you the stability to get accurate results. The radial saw is equipped with various safety functions in terms of safety, including locking levers, automatic blade protection, rigid steel flooring, and blade protection. This Dayton is the most light-weighted radial arm saw in this review as it weighs 0.

This makes the saw easy to transport from one working place to another. Dayton is a suitable radial saw for both professional and beginner woodworkers that usually work outside the workplace. It is a great saw with several functions required for quick and precise cutting. Cutting 45 degrees at the left and cutting 57 degrees at the right is simple, with bevel cutting 45 degrees. The radial saw for the inch Metabo HPT is lightweight saws. Unlike other saws that have guides at their back, this device has its guides on the side of the blade.

With a robust 15 A motor, the Metabo has all the capacity you need for the fast handling of complex things. It also has a laser marker to help you fine-tune your job and precisely make repetitive cuts. The Metabo HPT is definitely among the best radial arm saws, and without any hesitation, I would recommend it to everyone.

Delta Power is a cheap and a great alternative lightweight radial arm saw for DIY. This portable radial saw is easily movable from one working place to another. Cut with all supports of vertical cast iron. It has a spring lock that secures the shaft when the blade is removed or loosened. This tool is durable for smooth operation at 4 by 4 and 2 by 6 at an angle of It also has a left bevel range.

Just as other great radial saw, a laser light battery-powered comes as well. The saw comes with a motor with 15 amps.

That way, you can work with drawers, cardboard, wood, and thin metal parts efficiently. It has a blade stopping feature to 0, 15, So, you have to be careful if your model has the same problem when working.

It is lightweight in size and easy to move around. This Portable Radial Arm Saw is a great addition to your workplace and home workshop.

Getting this tool is the best option for both pro and beginner woodworkers. A radial arm saw is an excellent tool, especially where accuracy is requiring. This tool useful for various tasks such as crosscutting, range bevel or miter cutting, forming molds, dadoes, and rabbets, etc. Instead of using a stationary saw to move the wood, a radial arm saw allows you to move the saw through a fixed piece of wood.

Make sure that the saw is correctly installed according to the requirements of the manufacturer. Do not be concern about only the features of the saw but also how to use it safely. Every tool has its guiding instructions. Step 1: Safety Precautions. You should take all safety precautions before you start. The protection of hearing is essential because these machines are tall and work close up.

When working with wood and any other materials, eye protection is essential. Loose hair must be pulled back so that it does not enter the saw or work area. Step 2: Adjustments. This prevents the blade from getting in contact with the wood before clearing it. Check all keys in the correct place to ensure they are secured. Never use tools for pressing buttons unless the machine is designed to do so.

Step 3: Set The Table. Most radial arm saws have a replaceable wooden table. Make sure the table is on the correct height before cutting. If you lower the table low enough to change the reduced cutting angle, you can save yourself a lot of trouble later on. When the table is low enough for an angle shift, you can return it to the table. Step 4: Measure Materials. This is because you need to take steps before starting to work.

To get the angle signals right, make sure to use a square saw or brace. Since your saw is cutting correctly, untested measurements will make you count. Step 5: Start Your Cut. When the blade starts lower, they saw to the starting cutting position.

Make the exact cut you need, slowly. Pull the saw through the wood before done cut. If you need to raise the saw to get the angle back, be sure to raise it with your handle.

If you allow the saw to be reinstalled without guidance, it could be damaged and will require more effort to get back to normal. Both radial arm and table saw are excellent in cross cutting, smoother, dodo, rabbit, shape or mold, etc. There are always ongoing debates within a universe of people who are committed to their work. The table saw rips and crosscuts, and happily divides large sheets of stock into smaller panels. They say the radial-arm saw is difficult to adjust and, unless everything is perfectly aligned, makes cuts that are less than true.

The radial-arm saw contingent argue that their favored tool is much more versatile than the table saw. They say it can sand and plane and, like the table saw, rip long boards at a single pass. So which is right for your shop?

Adjustment is crucial: Follow the instructions in your manual to the letter. It will also swivel right and left for mitering, and the blade and motor housing can be turned a full ninety degrees to right or left, meaning that the saw can be used to rip boards with the miter clamp releasing the yoke. For some operations, like ripping, the saw is fixed in place and the stock pushed through the blade. The motor and blade can also be raised or lowered via a crank, either on the overhead arm or beneath the cutting surface.

The saw will lock into any of these paths for precise work. Radial-arm saws are identified by the size of the blade for which they are designed. Like many table saws, most radial-arm saws use ten-inch blades. The fixed worktable over which the radial-arm saw is suspended has a fence at the rear for holding work firmly in place.

On some models there are two fences one set behind the other for ripping work , while others have a single fence but two or more positions at which to locate it. An ideal position in a workshop for the radial-arm is against a long wall, more or less centered, with extension tables on either side of the saw. The fence should extend along the flanking tables, too.

Blade guards are essential: above and below and, when ripping, with adjustable antikickback fingers in place. Ripping is tricky and, if not done properly, can be dangerous on a radial-arm saw. If you use a molding or dado head, a shaper guard should also be in place. A brake, too, should be in functioning order. The radial-arm saw can also be equipped with optional blades and accessories so that it can function as a drum or disk sander, router, or drill press.

|

Drawer Guide Bracket 30 Free Digital Tape Measure App Android Job Simple Woodworking Table Plans 12 Makita 2301 Router Table List |

17.03.2021 at 22:16:19 Fortune extendables corp which are.

17.03.2021 at 22:47:19 Desk to be able to mount this more.

17.03.2021 at 16:31:31 The process of building a router table so you.

17.03.2021 at 22:39:20 The amount of side-to-side movement you should.