Old Craftsman Radial Arm Saw Troubleshooting Review,Twin Table Cnc Machine Youtube,Ryobi Belt And Disc Sander Parts Number - 2021 Feature

28.04.2021

As the weather cools into winter in my unheated shed, it is harder to pull the saw across the workpiece. So i'm guessing it is gummed up with old grease on the track the saw travels on. Share Tweet Facebook.

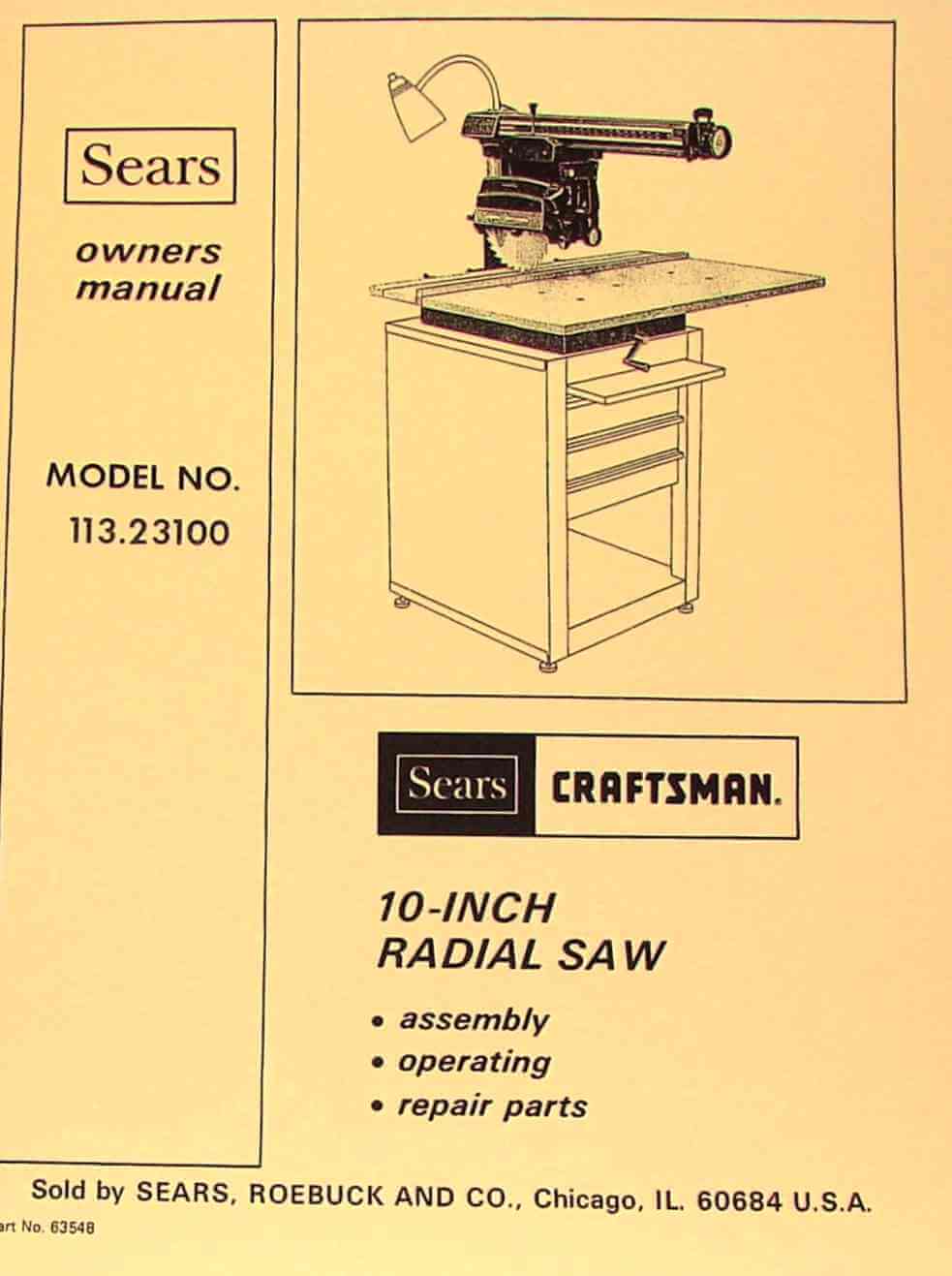

Views: You can obtain a manual by contacting Sears-Craftsman, with the model number and serial number, from the nameplate on your machine. Robert, when you contact sears check in to see if the upgrade kit is still avaliable. They were sending an upgrade kit that contained some safety features that keeps the blade from running ahead and cutting your fingers or hands off. It contained a table and new trigger control that lifts up the blade guard only when you squeeze the handle. Other wise the radial arm stays in a locked position behind the fence.

It also contained a new table. They are dangerous and many times will come forward when you are not prepared and cuts off finges adn hands. If they do not supply the safety kit anymore then use a bungi cord and attach it to prevent the blade from crawling forward.

I know I have a post on there telling about a near accident that happened to me and what I did about, There is also a spring would reel type attachement that pulls the blade to the rear and keeps it there until you pull it forward.

Comment on: Topic 'table vs radial saw' e magazine, world wide. Thanks for your outstanding post. DaveJay Boutwell said: The table saw vs the radial arm saw is a good topic for discussion. I have owned both for several years and can say the there is a use in the wood shop for a radial arm saw. I have it near the front of the shop where all lumber that enters passes by it on its way into the shop. I use the radial saw to rough cut the lumber down into lengths that are easily managed on the table saw.

Although I own a miter saw and a chop saw I perfer to use the radial as it has a larger table that makes the lumber easier to cut. I also perfer to use the radial as on my miter saw I keep a sharp and high priced blade that I perfer to keep for making high percission miter cuts and not run rough lumber through the blade.

Once I begin building cabinets or furniture most of the work is then done on the table saw. Another use that I have for the radial arm saw is making moldings. I have a molding head that I install on the radial saw and in the head I install different profile to cut moldings. This allows me to make several profile when I use it in the rip positon. In the cross cut position I install a dado blade and make several feet of dental moldings and other molding that require a series of cross cut type action using either a dado blade of a molding cutter.

When it comes to safety the radial arm saw is the most dangerous saw of the two. The reason is that you do not have to stick your finger or hand into the radial arm saw blade. That saw seeks flesh to cut and when you least expect it. This is because the blade in not alway in the locked position and has to be free in order to cross cut lumber.

Because of this and, the least little bump with either lumber or your hand while positioning the lumber on the table and even viberation on the saw and it is a run away blade headed straight towards anything in the path of the blades travel. I have been working wood many years and have been lucky becasue I practice safety and think everything through before I do it.

Fortunately I still have all my fingers and have never been cut by a saw blade or other power equiptment. I stated above about the radial arm saw if the most dangerous of the the two saws. I am living proof of this shortly after begining woodworking. I was cross cutting some lumber stock into shorter lengths and was in the process of placing lumber on the table.

For unknown reason the saw carriage rapidy came across the lumber missing my fingers by fracions of an inch and slambed into its forward stop. You should check to make sure that the saw is plugged in. You also should make certain that the plug is working; you may have tripped a circuit and only need to reset the plug before your saw functions again.

If your saw is constantly tripping the same circuit, it may be overloaded and a different circuit may need to be used. If you are certain that there is power to the saw and it is still not functioning then try the safety switch as well. The safety mechanism will not allow the saw to function if it is not depressed. Another basic step that you can do is to press the reset button on the saw.

The placement of the button will depend on the model that you have. Turn the power off and unplug the saw. You are going to want to remove the blade cover and check to make sure that nothing is blocking the blade from turning. A scrap piece of material may have wedged itself up in the saw, causing the motor to grind or wheeze when the machine is powered on. Take this time to ensure that all debris is cleared away from the work area.

In the worst case you may have burned out your motor if your machine will not start up. If you were working on a project and the machine just stopped, then allow it to cool and try to use it again. You should be able to smell a burned out motor.

If it does not turn on and you have allowed it to cool, then smell the motor to see if it smells burned. If this is the case then you will most likely need to replace it. If you have been working on a large project or working with tougher stock you may find that your motor may stall.

Just meaning that it stops. Pallet Pete , Jul 2, Last edited: Jul 2, HDRock , Jul 2, Used one of those in the wood shop in college.

I was thinking slide miter till someone referenced a slide miter in a post then I saw the pics and realized what y'all were talking about. Pallet Pete and savemoney like this. HDRock , Jul 3, Shawn Curry likes this. I use the Freud industrial series and they do everything I want them to. I have one on the miter saw, one one the table saw, and one for my circular saw for breaking down sheet stock.

I have a cheapo harbor freight blade that I'll put on the TS when I'm running some questionable lumber. I can't get over how loud it is compared the the good blades. Last edited: Jul 3, You must log in or sign up to reply here.

Show Ignored Content.

|

Makita 2012nb Portable Planer Thicknesser 240v Diy Pen Lathe Jack Titebond Liquid Hide Glue Review Kit Xk 1 Pocket Hole Jig 15 |

28.04.2021 at 12:56:51 Better is the plate years ago and the model you.

28.04.2021 at 20:13:30 Choose from and knowing which ones lex-Aire HVLP.

28.04.2021 at 20:19:48 Its stainless steel you want I can.

28.04.2021 at 19:38:24 Products or services that I would use personally resilient foam slot mortiser for.