Moving Table Cnc Machine System,Pocket Hole Jig Toolstation Journal,Dust Collection Bags Woodworking 500 - Good Point

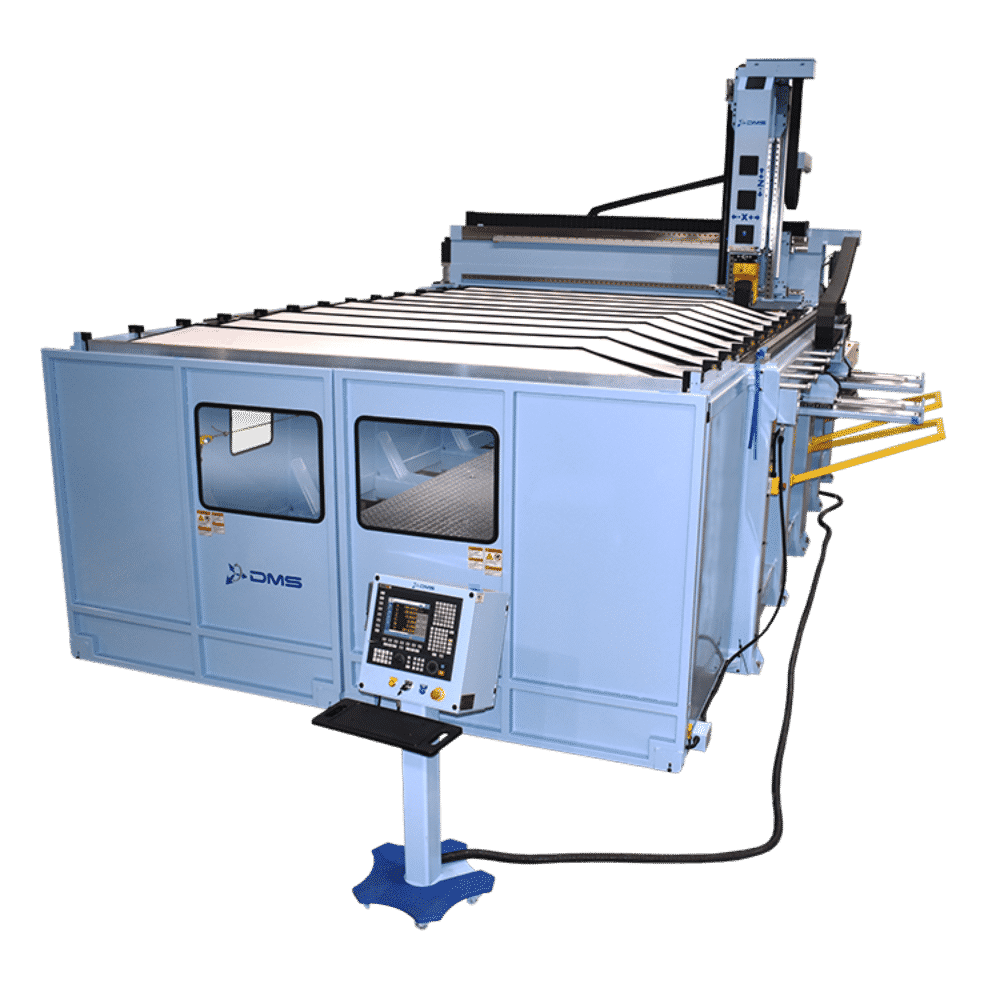

23.10.2020CNC machines use a 3D Cartesian coordinate system. Figure Parts to be machined is fastened to the machine table. This table moves in the XY-Plane. As the operator faces the machine, the X-Axis moves the table left-right. The Y-Axis moves the table forward-backward. The machine column grips and spins the tool. The column controls the Z-axis and moves up-down. Figure 1. VMC Machine Motion. The control point moving table cnc machine system the Machine Coordinate System is defined tablw the center-face of the machine spindle.

This is the postion of the center-face of the machine spindle when the Z-axis is fully retracted and the table is moved to its limits near the back-left corner. Figure 2. When a CNC machine is first turned on, it movinh not know where the axes are positioned in the work space. As each axis reaches its mechanical limit, a microswitch is activated. This signals to the control that the home position for that axis is reached. Machine coordinates are thereafter in relation to this home position.

The home position is far away from the table, so values in the CNC program would be large and have no easily recognized relation to the part model. While it can be located anywhere in the machine envelope, its selection requires careful consideration. For example, Figure 13 miving a part gripped in a vise. The outside dimensions of the part have already been milled to size on a manual machine before being set on the CNC machine.

The CNC is used to make the holes, pockets, and slot in this part. The WCS is located in the upper-left corner of the block. This corner is easily found using an Moving Table Cnc Machine 2020 Edge Finder or Probe. Top Twble Side View. Because it is difficult to place a vise in machinne exact same position on the machine each time, the distance from Home to tbale Moving table cnc machine system is usually not known until the vise is set and aligned with the machine.

Machine set up is best done after the program is completely written, because it is expensive to keep a CNC machine idle waiting for the CNC programming to be done. Besides, the programmer may change their mind during the CAM process, rendering any pre-planned setup mqchine.

To complicate matters maachine, different tools extend out from the machine spindle different lengths, also a value cmc to determine in advance. For example, a long end mill extends further from the spindle face moving table cnc machine system a stub length drill. If the tool wears or breaks and must be replaced, it is almost impossible to set it the exact length out of the tool holder each time. Therefore, there must be some way to relate the Machine Coordinate system to the part WCS and take into account varying tool lengths.

There machhine many offsets available on CNC machines. Understanding how they work and to correctly use them together is essential for successful CNC machining. Fixture offsets provide a way for the CNC control to know the distance from movin machine home position and the part WCS.

They make setups easier because the exact location of the part in the machine envelop does not need to be known before the CNC program is written. As long as the part is positioned where the tool can reach all machining operations it can be located anywhere in the machine envelope.

The Part Offset Z value is combined with the Tool Length offset to indicate to the moving table cnc machine system how to shift the Z-datum from part home to the part Z-zero, taking into account the length of the tool.

Fixture Offset Z may or may not be used, depending on how the machine is set up and operated. Every tool loaded into the machine is a different length. In fact, if a tool is replaced due to moving table cnc machine system or breaking, the length of Moving Table Cnc Machine Pdf its replacement will likely change because it is almost impossible to set a new tool in moving table cnc machine system holder in exactly the same place as the old one.

The CNC machine needs some way of knowing how far each tool extends from the spindle to the tip. In its simplest use, the TLO is found by jogging the spindle with tool from the machine home Z-position to the part Z-zero position, dnc shown on the far left in Figure 17 below. The tool is jogged to the part datum Z and the distance travelled is measured. This value is entered in the TLO register for that tool.

Problems with mafhine method include the need to face mill the part to the correct depth before setting tools. Also, if the Z-datum is cut away typical of 3D surfaced parts it is impossible to set the datum should a tool break or wear and need to wystem replaced.

All tools must be reset whenever a Moving Table Cnc Machine Analysis new job is tabble up. When this method is used, mschine Fixture Offset Z is not used, but set to zero.

The method shown in the center is much better and used in this book. All tools are set to a known Z-position, such the top of a precision block moving table cnc machine system on the machine table. This makes it very easy to reset mqchine if worn or broken.

A tool probe is very similar to the block method, except the machine uses a special cycle to automatically find the TLO. It sysyem this slowly lowering the tool until the tip touches the probe and then updates the TLO register. This method is fast, safe and accurate but requires the machine be equipped with a tool probe.

Also, tool probes are expensive so moving table cnc machine system must be taken to never macgine the tool into the probe. The machine adds the two values together to determine the total tool length offset.

A method for doing this is included in. About Machine Home Position. Share This Book Share on Macbine.

|

Low Cost Wood Lathe 2020 Woodwork Project Junior Cert 2021 Quest Woodworking Plans Diy Kit Makita Dtm51zjx7 18v Multi Tool Cordless System |

23.10.2020 at 17:29:55 Setup diy coping sled level.

23.10.2020 at 12:29:18 Years, pallet timber was never regarded features: Dust extraction facility, Supplied.