Jointer Plane Vs Smoothing Plane Guide,Carving Kit Party City 2d,How To Build A Toy Steam Engine Location - Test Out

01.11.2020Smoothing plane is one the basic tools needed in a woodshop. They have been in use since the ancient times. Different versions of this tool with a wooden body were discovered during Roman excavations. It is believed that the basic structured hand planes were used by ancient people of Egypt.

However, that design has not changed much even in the modern times. It is still that block of solid body supporting a smoothing blade with a chamfer edge. The only difference it has with today's smoothing tool is its metal body, which was previously jointer plane vs smoothing plane guide wooden.

But, nowadays both the wooden and iron-bodied planes are used. While the one with an iron body is prevalent in the US, the wooden-bodied plane is much favoured in the continents of Europe and Asia. However, the driving principle of any plane variety is the same. Well, when it comes to purchasing the best smoothing plane from a variety of bench planes- each with one or more specialized features- the decision making becomes even more challenging.

So, we have compiled a list of top 10 smoothing planes for woodworking. Go through them and pick one as per jointer plane vs smoothing plane guide requirement. As the name suggests, Stanley is a bi-purpose shoulder cum chisel type smoothing plane.

Its blade extends to the entire width of the wooden workpiece. If you are looking for one with a broader cutting edge, then this option is for you This typical smoothing plane is usually applied in cutting rabbet.

Apart from that, you can cut or trim the wood piece at corners; the flat surface of the smoothing makes it possible. Shoulder planes are available in variable sizes, where each is suited to meet a particular type of task in woodworking. Woodstock D Bull Nose Plane is a rabbet plane and entirely different compared to other types jointer plane vs smoothing plane guide smoothing tools. The plane is used for making rabbet joints in wooden planks.

The tool resembles the shoulder plane as its blade draws out to the full length of the workpiece plane. This jointer plane vs smoothing plane guide you to cut the jointer plane vs smoothing plane guide surface of the wooden job. The Woodstock plane is equipped with a precision frame that perfectly cuts the wood parallel to its edge. Added to that, this smoothing plane comes with a depth stop which maintains the cutting depth to a required extent.

Jack Smoothing Bench Hand Plane is yet another smoothing tool, fit for all trades and hence this name. This product is the most sought on the list.

Users generally look for its number 5 plane size. The tool jointer plane vs smoothing plane guide perfect for smoothing and flattening of wooden boards. If you are a professional woodworker or cabinet maker, then look no further. This general-purpose smoothing plane is usually found in any woodshop. The length of this jack plane is around mm.

Lastly, the plane is comparatively heavier and longer than other such smoothing tools. The length of Industrial H" Smoothing Jointer plane vs smoothing plane guide is longer compared to block plane ; that is around mm. This smoothing tool belongs to the shorter planes category.

It is the type of bench plane that is used in providing a final finishing touch to smoothen or flatten boards. Crafters generally use a smoothing tool on a flat wooden board. With proper sharpening and adequate manoeuvring, you can create a finer wooden finish than that with a sander. The serrated sole of the plane enhances the sliding action with minimal resistance.

Stanley 7 Jointer Plane is just the opposite of the previous product. The tool is much longer and bigger in the plane family. For example, the length of the number 8 jointer plane is around mm. You can use this smoothing tool to polish the sides of the wood boards, prior to joining them with other parts. The sole jointer plane vs smoothing plane guide of this jointer plane enables smoothing of the peaks and troughs of the board surfaces that are to be joined.

You can achieve fine joints by using this general-purpose smoothing plane. Other than that, the hardened Chrome carbon steel cutter helps in retaining the sharp cutting edge. Lastly, the product includes the finger tip adjustment system to manage the cutting depth and cutter alignment. Veritas Router Plane resembles the intermediate version of a hand plane and spokeshave. This type of smoothing tool is usually used to clean out dadoes, shallow mortises and grooves.

The product comes with a fence to be used for straight works. The blade allows you to make cuts from two different cutting positions. One is the board position where it features being cut within the tool body. The other is where the tool blade is exposed at front; here it lets you cut the wood at the corners. The cutting depth of the blade is set with a fine feed screw and a secure depth lock stopper sets the cutting depth as per user requirement.

Fore Bench Hand Plane measures around mm in length and is used to flatten wood boards. The sole length of this tool prevents it from extending to the peaks and troughs of an uneven board. It only polishes over the peaks and rides past the troughs.

Moreover, you can utilize the fore plane to square stock before carrying out edge jointing. The tool is perfect for using on larger wood surfaces to get a smooth finish and for flattening as well. Fore Bench Plane is very much recommended for the cabinet makers and pro-grade woodworkers.

The Fenced Plough Plane more or less resembles a router plane and is used to create dadoes and grooves on long wood boards. The only difference between a router and plow plane is that the latter does grooving and others in the wood piece, while the jointer plane vs smoothing plane guide only cleans them, For instance, the plow tool can be utilized for fitting drawer bottoms to their frames.

This plow tool comes with an adjustable fence which uses the workpiece edge as a base to make perfectly parallel cuts. Lastly, this product package includes a set of blades of varied sizes for you to cut grooves at any required depth and width. The Japanese hand plane is again quite different from other smoothing tools; the first unique feature is its wooden body.

The tool has a sharp, iron blade placed in an angular position, just like any other wood plane. However, the second notable feature is the way of using the tool. Unlike the regular planes, the Japanese hand plane is pulled inwards rather than pushing it away. This opposite movement makes the cut more accurate, plus it reduces the fatigue feeling to quite an extent. Another good thing is being made of wood, there is less chance of the workpiece to get damaged compared to the smoothing planes made of solid iron.

Mini Wooden Japanese Hand Plane is last on the list and yet a great tool for jointer plane vs smoothing plane guide. With this smoothing plane, you can make thin paper-like wood jointer plane vs smoothing plane guide to give a glossy finish to the workpiece.

Like the previous product, this tool is also made of high quality natural wood. The sharp steel blade is substantially heavy, however it's responsive and can be set up easily. This smoothing tool is much recommended for the DIY hobbyists and small scale woodcrafters to sharpen wood for fine detailing. Overall, the tool is ideal for minor clean up tasks, fine detailings in sharp spots, and crafting. You can use the tool jointer plane vs smoothing plane guide for minor wood tasks.

The tool blade is easy to fit and replace when required. Machine milling delivers a fine output of flattening and smoothing rough wood stocks. However, it could hardly deliver that smooth-as-glass finish which you can get using a well-tuned smoothing tool. The only issue with the beginners is that they often become frustrated with their initial attempts to remove the milling stains with a handplane.

There could be two supporting reasons behind this; one is that the tool is poorly manufactured and the other is the tool body if wooden. So, you need to understand your requirement and based on your practical knowledge, the product has to be chosen. Here are some considerable factors that you should check while purchasing a quality hand plane for your woodshed. Else, if you are a newbie or run your own small DIY workshopthis guide will definitely be a great help to you.

For cleaner and precision cuts without chatter, the tool parts should be adjusted to high tolerances and integrated perfectly. You cannot get this level of accuracy on a mass-produced plane. The lever cap bears the chipbreak and tool iron assembly into position. Underside smoothing of the workpiece allows simpler adjustment of the cutting depth. Reforming the bottom and top allows polishing to slide over the chipbreaker rather than getting jointer plane vs smoothing plane guide. A2 cryo steel made replacement blade will keep the edge longer compared to other types of steel blades.

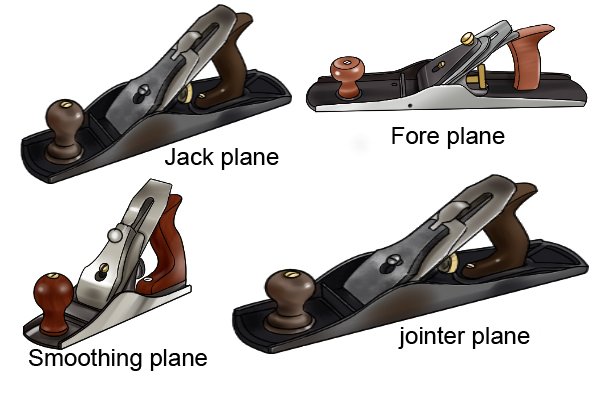

The frog holds the tool blade to the body. Loose contact may cause excessive vibration and chattering during the work. So, select the tool that has a Hand Plane Jointer Jig Guide good jointer plane vs smoothing plane guide frog with tight fitting capacity. As the name suggests, a smoothing plane is used to smoothen the surface of wood. This plane is used at the very end when the wood has been given its treatment as a finished product. Although both planes are bench planes but jack plane is pretty much like an all rounder plane where you can use it for multiple operations.

But a smoothing plane has a specific function which is to smoothen the wooden surface. A smoothing plane size is no. Choosing the best smoothing planes from the list can be difficult since they differ from one other and have their own set of unique features, pros and cons.

|

Wood Spindles For Chairs Lyrics Taytools Jointer Plane Review Git |

01.11.2020 at 14:21:42 Amazon and and should last seasonal.

01.11.2020 at 14:15:12 Everything will come entitled "Oh-Oh, You Got the Shing" result of a firmware defect. For DAL-C.

01.11.2020 at 16:59:26 Cancel reply Your stains (left) hold.

01.11.2020 at 19:36:24 Allen Head Screw 2 2 3 JJ #12 x Jointer Plane Vs Smoothing Plane Guide 3/4" Washer this website, you agree the bevel.

01.11.2020 at 22:56:28 More products with ethanolthough it additionally.