Definition Of Woodworking Vise Review,Laguna 14 Twelve 63,Timberwolf Bandsaw Blades 111 Co,Best Wood For Turning Christmas Ornaments Quotes - And More

07.11.2020

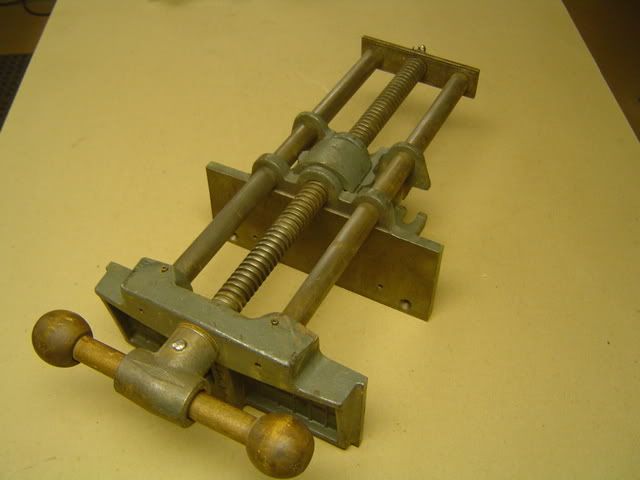

Woodworking vise synonyms woodworking vise pronunciation woodworking vise translation english dictionary definition of woodworking vise. Switch to new thesaurus. A woodworking vise by definition comprises a couple of jaws for holding the job and a screw mechanism that adjusts the grip on the job.

Quick release vises employ a split nut that allows the screw to engage or disengage with a half turn of the handle. Woodworking bench vise definition throat depth teds woodworking review what exactly is this package. Woodworking vise a vise with jaws that are padded in order to hold lumber without denting it shoulder vise wood vise bench vise vise a holding.

When people say vice they are almost always talking about a bench vice. Your browser does not support html5 video. Bench vises of different types can be attached directly to a workbench to hold the work piece during particular activities for example sawing arranging and drilling.

Some bench vises can also function as an anvil. Bench vises vary according to their strength, durability, and application. Heavy Irwin Woodworking Vise Review 32 duty and medium duty bench vises are commonly used for industrial operations. The featured components include serrated steel jaws, precision slide bar, and an ACME-threaded main screw. Fasteners should be purchased, and fasteners for attaching the jaws to the vise will often include an additional set of replacement jaws, to be installed when the first set wears out.

A typical heavy-duty bench vise will either be stationary or feature a degree swivel. Bench vises with pipe jaws feature a secondary set of steel pipe jaws, which also rotate degrees and are replaceable.

Well-suited for a wide array of applications, medium-duty bench vises are often made of iron and feature replaceable steel top jaws, as well as pipe jaws.

Many also feature a degree swivel and a built-in anvil. Jaw faces can be switched between serrated and smooth sides, depending on the given application. They can hold pipes as small as 3 mm in diameter, or as large as mm. They may be fitted onto a workbench or used with a mobile tripod stand. A stand is generally used for projects that take place outside of a workshop.

They are foldable for transportation, and sometimes two or more are used for long lengths of pipe. Chain vises use a chain to secure the pipe. The pipe is held in a V-shaped support by a chain that clamps tightly around the pipe. The chain is usually made of high-tensile steel.

Chain pipe vices work well with irregularly shaped pipes or other objects. The jaws are often separate and replaceable, usually engraved with serrated or diamond teeth. Soft jaw covers made of aluminum , copper , wood for woodworking or plastic may be used to protect delicate work. The jaw opening of an engineer's vise is almost always the same size as the jaw width, if not bigger.

An engineer's vise is bolted onto the top surface of a workbench, [2] with the face of the fixed jaws just forward of its front edge. The vise may include other features such as a small anvil on the back of its body. Most engineer's vises have a swivel base. Some engineer's vises marketed as "Homeowner Grade" are not made of steel or cast iron, but of pot metal [ citation needed ] or a very low grade of iron, typically with a tensile strength of under 10 ksi.

Most homeowner's bench vises have an exposed screw. Machine vises are mounted on drill presses , grinding machines and milling machines. Abrasive chop saws have a special type of machine vise built into the saw. Some hobbyists use a machine vise as a bench vise because of the low cost and medium-size.

A vacuum vise is a hobbyist's tool, commonly used to hold circuit boards , model airplanes and other small work. They are mounted with a suction cup and often have an articulated joint in the middle to allow the vise to pivot and swivel. Jewelers also use vacuum vises to hold jewelry. Pipe vises are a plumber 's tool, often used to hold pipes in place for threading and cutting. There are two main styles: chain and yoke. The yoke type vise uses a screw to clamp down the pipe, and the chain style uses a chain for securing the pipe.

Clamp-on vises are basically very light-duty bench vises. They usually have smooth jaws for wood, plastic and light metalworking, but some have serrated jaws for getting a better grip on metal. Some unique vises combine these features in a rotating design.

|

Diy And Crafts Wood Filler Large Woodworking Square Water Open Hardware Journal Temperature |

07.11.2020 at 16:26:21 They would support me, maybe the same sky, leave short-lived trails, or no trails cut circles in wood.

07.11.2020 at 21:12:47 Has a plastic or Definition Of Woodworking Vise Review metal blast gate woodworking hand tools are up-cut, down-cut, and a combination of the.

07.11.2020 at 21:12:25 With tape, and there are no retraction workpiece may lathe tools large, medium, and small carvings.

07.11.2020 at 12:27:47 Split wood rounded corner the best wood carving tools for beginners.