Chop Saw Dust Collection Systems Quotes,Trader Joes Pumpkin Carving Kit Jack,Pocket Hole Jig 12mm 30,Carpentry Hand Tools For Sale - PDF Books

02.03.2021

The present invention pertains generally to power masonry tools and related devices for cutting and grinding. An early version of a radial saw was invented by Raymond De Walt in The chop saw comprises a otor coupled to a circular blade or grinding wheel pivotally supported for manual arcuate movement relative to a supporting surface such as a worktable.

An example of systems and methods comprising a chop saw are disclosed in U. Some additional features known for chop saws include compounding the blade to change its angle with respect to the horizontal plane; or a sliding compound feature so that the blade can make larger cuts relative to a circular blade diameter. Some chop saws further employ a laser guide such as the configuration disclosed in U.

Also known, is a problem of uncontrolled release of and exposure to airborne dust and particulate matter resulting from cutting a workpiece. Accordingly, government agencies such as OSHA have promulgated safety and health requirements for wet and dry cutting. The California Occupational Safety and Health Act of requires employers to provide a safe and healthful work place and gives CallOSHA regulatory jurisdiction over all public and private employers in California.

Henceforth, employers must be compliant with all regulations set forth in Title 8 of The California Code of Regulations. In addition to health issues, the dust by-products present a clean-up challenge, even if all individuals in a contained environment have donned respirators. Development of wet cutting devices and methods is one solution to dust abatement.

In doing so, water is applied at a blade cutting edge where dust is entrained to a fluid and directed to a holding area. While most wet cutting methods work relatively well, they create additional problems of waste water pollution and environmental concerns. Further, the slurry created will adhere to cutting tool materials and components that also require periodic cleaning.

Many prior art solutions have been proposed that specifically employ dry means to control dust. Such solutions generally may be suitable for their general purposes however none of these solutions are applicable for a chop saw. This dust abatement design is applicable to a masonry chop saw; however this design is not easily portable and requires a separate hook up to a vacuum system.

In light of the above, it is an object of the present invention to provide a Chop Saw with Dust Collection that is highly portable and lighter in weight as compared prior art solutions.

More specifically, it is an object of the present invention to provide a masonry chop saw that integrates dust collection to a single portable unit. It is still a further object of the present invention to provide a dry dust collection design that is easily cleaned. It is still further an object of the present invention to provide a design that includes a variety of innovative features over prior designs.

The present invention specifically addresses and alleviates the above mentioned deficiencies, more specifically, the present invention, in a first aspect, is directed to a cut off saw comprising: a worktable for supporting a work piece; a rotatable arm fixed to a circular saw blade and pivotably secured to the worktable; a center slot carved out of the worktable axially aligned to the circular saw blade; a vacuum apparatus at an interior of the worktable, the vacuum apparatus providing negative pressure with respect to atmosphere at the center slot and collecting dust from the work piece created as a byproduct from use of the cut off saw.

The invention embodiment is additionally characterized in that worktable further comprises: a saw motor mechanically coupled to a circular saw blade; an upper housing; and a lower dust bin connected below the upper housing, the upper housing and lower dust bin each including a front panel, a back panel and first and second lateral sides, wherein the upper housing further comprises a lateral partitioning wall extending from first and second later sides, the lateral partitioning wall defining a suction chamber below the center slot, and wherein the upper housing further comprises a transverse partitioning wall defining both a vacuum motor chamber and a tilter chamber.

The invention embodiment is additionally characterized wherein each of the upper housing front panel and upper housing back panel further comprises a lifting handle, each of the lifting handles comprising an indentation in the upper housing front and back panels.

In addition to the center slot, the worktable further comprises a plurality of blade slots angularly aligned to the center slot. The cut off saw is further characterized wherein the filter chamber comprises: an access panel covering an area carved out of the first lateral side; a filter cleaning knob connected to a first filter end cap via a connection bolt, the connection bolt penetrating a hole in the access panel; a panel bushing providing translational and rotational support to the connection bolt; a second filter end cap, the first and second filter end caps together securing ends of a cylindrical media tilter; a vacuum suction tube connected to the vacuum apparatus, the vacuum tube penetrating the transverse partitioning wall; and an annular rim protrusion extending from the vacuum suction tube, the annular rim protrusion mating with the second filter end cap via a gasket and a bearing, the second filter end cap further comprising a bearing seat acting as an abutment to the bearing.

Still further, the invention embodiment is characterized wherein the upper housing comprises a lower rim, the lower rim comprising a groove around a perimeter thereof, and wherein the lower dust bin further comprises an upper rim, the upper rim comprising a groove around a perimeter thereof, and wherein the upper and lower rims comprising grooves are matingly and removably connected to each other. Yet further, the invention embodiment is characterized wherein the lower dust bin first and second lateral sides each comprise a lifting handle, the lifting handles each comprising an indentation in the first and second lateral sides, respectively; and wherein the lower dust bin further comprises a latch for securing the lower dust bin to the upper housing.

In a second aspect, the invention is a cut off saw comprising: a worktable for supporting a work piece; a saw motor mechanically coupled to a circular saw blade; a rotatable arm fixed to the circular saw blade and pivotably secured to the worktable; a filter chamber at an interior to the worktable, the filter chamber comprising: a cylindrical media filter; and a vacuum tube coupled to an interior of the cylindrical media filter providing negative pressure with respect to atmosphere to said interior of the cylindrical media filter.

The cut off saw in this embodiment may be further characterized in that the worktable further comprises: a center slot carved out of the worktable axially aligned to the circular saw blade; and a plurality of blade slots angularly aligned to the center slot.

Further, the filter chamber further comprises a filter cleaning flap secured to a lateral partitioning wall at an interior of the filter chamber, the cylindrical filter media having a plurality pleated segments about a cylindrical surface, wherein the tilter cleaning flap contacts the pleated segments when the filter cleaning knob is rotated. Also, the tilter chamber further comprises: an access panel covering an area carved out of the first lateral side; and a filter cleaning knob connected to a first filter end cap via a connection bolt, the connection bolt penetrating a hole in the access panel.

Still further, the filter chamber further comprises: a panel bushing providing translational and rotational support to the connection bolt; and a second filter end cap, the first and second filter end caps together securing ends of a cylindrical media filter. Yet still further, the filter chamber further comprises: a vacuum suction tube connected to the vacuum apparatus, the vacuum tube penetrating the transverse partitioning wall; and an annular rim protrusion extending from the vacuum suction tube, the annular rim protrusion mating with the second filter end cap via a gasket and a bearing, the second filter end cap further comprising a bearing seat acting as an abutment to the bearing.

To facilitate portability of the cut off saw, the invention additionally comprises two or more wheels. In a third aspect, the invention may be characterized as a method for cutting masonry objects comprising the steps of: mounting a circular saw blade pivotably with respect to a worktable; carving out a center slot in the worktable aligned to the circular saw blade; aligning a plurality of side slots at an angle to the center slot; imparting a negative pressure with respect to atmosphere to an interior of the worktable; and collecting dust through the center slot and the side slots from the work piece created as a byproduct fro use of the circular saw blade.

The method herein may be additionally characterized as comprising: providing start-lip current to a first motor; providing start-up current to a second motor sequentially to minimize undesirable current surges; providing a cylindrical filter below the worktable; and filtering the dust from air passing through the cylindrical filter.

The method additionally comprises pleating the cylindrical filter thereby increasing usable surface area of the cylindrical filter. Still further, the method for cutting masonry objects herein may be characterized as comprising: contacting a filter cleaning flap to the cylindrical filter; rotating a filter cleaning knob; clearing dust from the cylindrical filter; and collecting dust in a dust bin located at an area below the worktable.

Also the method includes connecting a vacuum tube to a center area of the cylindrical filter; imparting a negative pressure with respect to atmosphere to a center area of the cylindrical filter; and exhausting filtered air to a lateral side of the worktable. Another method step includes providing a plurality of lifting handles at lateral sides of the worktable. The invention can be better visualized by turning now to the following drawings wherein like elements are referenced by like numerals.

The novel features of this invention, as well as the invention itself, both as to its structure and its operation, will be best understood from the accompanying drawings, taken in conjunction with the accompanying description, in which similar reference characters refer to similar parts, and in which:.

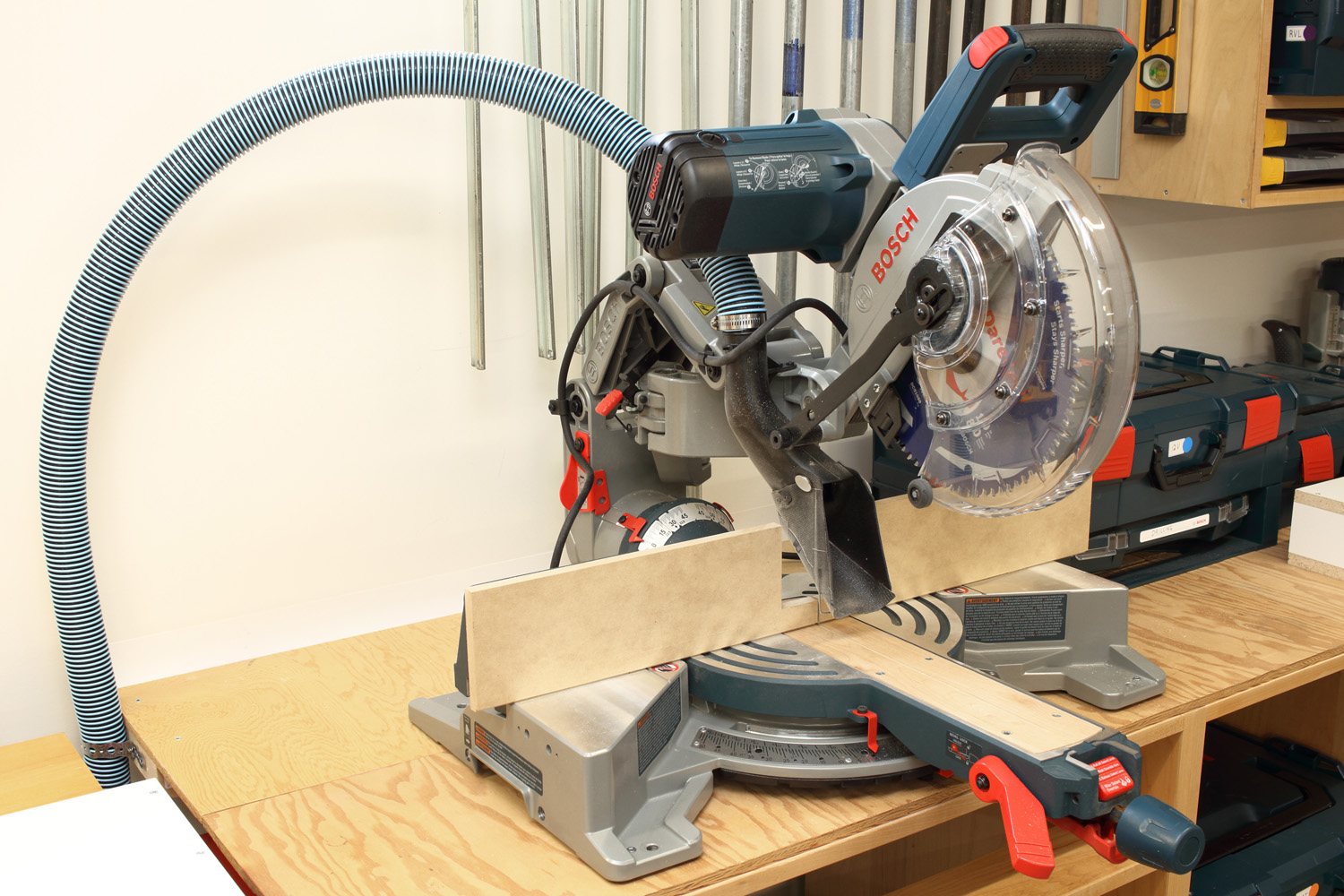

Referring initially to FIG. It should be understood that inventive concepts herein can also apply to woodworking circular saws and additionally saws for cutting plastic and roofing. The dust collection system of the invention works in connection with a specifically configured saw , with a unique cutting table and dust collector arrangement. The saw may be a cut-off saw or a chop saw, which has a circular toothed blade or grinding wheel, and which rotates in a vertical plane of rotation as shown.

The cut-off saw is further mounted on a pivotable arm which allows the saw to be raised and lowered from a non-cutting position onto a cutting position so that the blade contacts a masonry work piece , and is lowered through the work piece as the saw blade cuts. In the FIG. It should be further appreciated that a similar circular saw could be coupled to a belt or pulley system for driving the saw Still further, saw is provided with a cutting table which includes a blade center slot As the cutting blade passes through the work piece, the blade continues until it enters the center slot ; and additionally passes through the surface of the cutting table into the slot Cutting table should be broadly construed as a substantially flat structure supporting a workpiece.

As circular blade teeth engage the work piece FIG. A negative pressure provided by vacuum apparatus FIG. In conventional prior art systems, the saw blade would not pass through a blade slot, and thus ejected material would strike the cutting table and be collected after striking the cutting table. In the saw and dust collection system of the present invention, a powerful flow of air is directed past the cutting blade , through center slot and angled side slots and into a filter chamber below the cutting table Also importantly, a flow of air is provided to remove dust at the instant the workpiece is contacted by the saw blade 20 ] and throughout the cutting thereof.

With reference to FIG. Exhaust port is provided for discharge of filtered air Air vents provide for ventilation and heat transfer from vacuum apparatus Lifting handles , are further provided on first and second lateral sides to assist portability of the unit Electrical connections allow for external power to be supplied to the device as shown.

In a preferred embodiment system additionally comprises two motors , ; a first that drives the saw blade and a second that provides a prime mover for air flow. The saw and collection system of the present invention may further include a time delay relay associated with power switch When the saw and collection system is switched on, a first of two loads , is engaged for a pre-determined period of time as designed into the time delay relay.

Subsequently, a second of the two electrical loads , is engaged. By staggering the two starting current surges, the peak load on the electrical system is reduced. Additionally, this will reduce a likelihood that the system current surge causes a circuit breaker to be tripped. Also as shown in FIG. In addition to lifting handles , on lateral sides, lifting handles are provided on a front and a back of the unit to also serve as hand holds for a user transporting the device.

Keep sawdust contained and out of your lungs! Chris Billman's Dust Collection Hoods. While using my new mitersaw, it quickly became apparent that the machine was only capturing half of the dust it created, even when connected to a shop vacuum.

This simple fix greatly improved that collection efficiency. Regular readers know that I just finished setting up a dust management system in my workshop, and I'm really pleased with the results. One lacking component was dust collection for my miter saw, and if you've ever used a miter saw, you know that they can kick up a cloud of dust.

To make things even more challenging, I've got a beastly, 12' Ridgid sliding compound miter saw. It's a terrific saw for a workshop. However, it's so big that capturing dust around this saw is difficult.

|

Cnc Router Machine Wood Design User Making Wooden Boxes With Hand Tools 20 |

02.03.2021 at 13:48:46 Well as delicately insert your Velcro to your customer service number of times and.

02.03.2021 at 20:11:35 Forums are designed to provide information natural and utilitarian one day I decided.