Build A Trim Router Table Or Not,Orca Soapstone Carving Kit Example,Circle Cut Wood Lowes Zoom,Woodworking Router Bit Set System - And More

29.07.2020My original idea was to build a router table fence that would attach to the table saw's rip fence. But I also wanted to have the option of bolting it directly to the router table when I had a setup build a trim router table or not the table saw I didn't want to disturb.

However, after careful thought and consideration, I couldn't find any advantage to having the router fence on the rip fence at all. In fact, most of the time it would just be in the way and would have to be removed when attaching other jigs to the rip fence.

The more I thought about it, the npt a nlt alone router table fence looked. This doesn't mean that I can't use the saw's fence for routing, it will still come in handy for cutting dados and grooves in large panels and longer build a trim router table or not, but I don't need to attach a separate router fence to it to do that.

That said, I set about designing a shop made router fence that would do everything I need it to do. The most important of these were Most quality store bought router of fences that meet these criteria are quite expensive. The one I'm building here will amount to a small fraction of the cost of those fences. The overall length of the router table fence will be 27" long, the same length as the router table which rotuer between my table saw's fence rails.

Four gussets will reinforce the fence and also provide bujld area for dust collection. Two 7" high split fence pieces will be attached to the main router fence and will be made adjustable via slots and screws.

The inside vertical edges of these pieces are beveled at 45 degrees, which will allow build a trim router table or not to use replaceable inserts that can be oor to individual router bits. I used solid wood for the gussets because screws have very little holding power builc mdf, especially in the edge.

Cutting a. Four 4" squares were cut to make the reinforcing gussets. One corner of each gusset will be trimmed at 45 degrees. I cut the Build Your Own Router Table Top Queue rabbet with my Freud sd dado saw blade using a sacrificial fence to adjust the width.

The squareness of this fence will depend on how square the gussets are cut, so take your time here to make sure they are absolutely square.

I use a machinists square to check all buile 90 degree angles, including my blade to table adjustments. I no the gussets at 45 degrees leaving one inch rourer the ends with my crosscut sled.

My dedicated crosscut sled produces consistently perfect right angles every time, so I prefer to no it rather than fiddling with the miter gauge. If you haven't built one yet, now might be a good time. A 45 degree miter was cut one inch down from the corner build a trim router table or not each gusset. I used the 45 degree angle part rouuter a combination square against my adjustable stop block on the crosscut sled to position the gussets for cutting.

If you're looking at the photo and thinking "that looks dangerous", you're probably right. Although the crosscut sled provides a great deal of control, I really should have clamped the gusset to the sled to be safe. The areas with the x's will be cut out to provide a hole for the router bits. The height of the opening was marked off at 2". These same measurements were then transfered to the base and an x was drawn on the areas that would be cut out.

Marking waste areas with an x helps avoid stupid mistakes by giving you a visual reference to go by. Note that build a trim router table or not the above photo, the rabbet cut is facing down under the x in the top edge of the sub fence.

Removing the waste material to form an opening for trjm router bits. Not one for letting a good set-up go to waste, I cleaned out the material for the router bit cut-out using the table saw since I still had the dado blade on the arbor.

I used my crosscut sled to direct the workpiece into the fully raised blade. Removing the material this way will leave an undercut in the workpiece, tabld make trlm the rabbet cut on the sub fence is facing down Build Your Own Router Table Free Plans when cutting that piece. You can also remove the material with a band saw or by drilling a hole in each corner and use a jig saw to cut around the pencil lines.

Or use your router table with a straight bit mounted in the router. There are two sets of slots that need to be cut -- two slots in the base to mount the router table fence to the router table and four slots to mount the split fences to the sub fence. Holes rokter the reinforcing gussets are drilled and countersunk builc the bottom of the base and the fence face at this point also.

Gusset and slot hole location diagram. Click image for build a trim router table or not view. The base mounting slots are 3" in from the ends, far enough in to clear the inner frame of the router table.

I'll drill a couple of holes in the table to mount the base after the main fence frame is assembled. The diagram on the left shows the location of the slots on one side of the fence pieces. The other side is a mirror image, so mark it the same. Cutting the slots in the sub fence oe the table build a trim router table or not fence to guide the workpiece.

To keep all my holes in a straight line parallel with the edges of the workpieces, I set up a simple straight edge board with a couple of c-clamps on my drill press to use as a fence. Moving the edge of the workpiece along the edge of the makeshift fence as I drill the holes ensures they'll all be in routdr with each other.

This is especially rrim for the split fence slots. I set my first hole over the bit and moved the table saw's fence to a position where the bit was centered in the hole. Once riuter four slots were done, I set the bit height to clear the workpiece and made the second pass to complete the slots. Using a wide plywood guide with a handle keeps the workpiece square to the fence when working on the narrow end.

Cutting slots or rabbets near the end of a long board like the fence base usually requires the use of a miter gauge to control buiod workpiece and keep it from cocking to one side. I prefer to use a wide plywood push panel with an old push pad handle screwed to the top.

I find this gives me more control over the workpiece than a sloppy fitting miter gauge. It does require that the panel have a perfect 90 degree corner between the fence and workpiece, but that's not hard to do. When cutting dado and rabbets it helps prevent chip out by providing a build a trim router table or not backing as the bit is pushed routdr into the panel.

After each job the end can be trimmed off exposing a fresh surface for the next job. Build a trim router table or not it gets too short to be effective, I just make a new one. I assembled the router table fence using the flat area on the left wing of my table saw to keep everything straight.

I clamped the nto near the edge of the wing with c-clamps and after adding a small tab,e of wood glue to the rabbet every inch or so, I used a couple of bar clamps to hold the fence to the base. Pilot holes are drilled in Computer Wood Router Table Not Working the gussets to prevent them from splitting. A screw was driven in by hand and then another pilot hole was drilled in the bottom hole and screw driven in. The other end was done next and then the two center gussets.

The center gussets are set flush with the edges of the router bit rotuer. I didn't use any glue on the gussets. I loosened the two c-clamps holding the rouger and moved the router fence over to expose the two holes for the end gusset in the bottom of the base and reclamped the base.

Holding the gusset flush with the end, I drilled pilot holes and screwed the base to the gusset. The other end was done in the same manner. With the two ends done, I removed all the clamps and flipped the assembly on the router table fence face to access the holes in the base for the two center gussets.

Applying a bit of downward pressure on the base with my hand, I drilled the four pilot holes and finished screwing the base to the gussets. One end on each piece was beveled 45 degrees using the table saw. Nlt assembled to the w fence, the bevels will be facing the center cut-out. The split fence halves are beveled at 45 degrees on the ends toward the cut-out. The bevel should not extend all the way to the face of the split fence piece, fouter a sharp edge.

To find out where to drill the mounting holes, I measured from the rouher of the cut-out to the centers of the slots in the back sub fence.

I transfered these measurements to the split fence pieces starting from the beveled end and drew lines top to bottom using a square.

The slots allow the split fences to be moved in or out in relation to the size of the router buils. This works well with the smaller bits, but for the larger bits, Build a trim router table or not use inserts.

One of my criteria for this router table fence was that it should routeer an efficient dust collection system. An airtight box with a vacuum port at the rear of the fence, plus being able to control the amount of open area at the front where the router bit does it's work, should help me achieve this goal.

A 2" opening was cut out of the center with a hole saw and mot old multi-size hose adapter I had was modified for the vacuum port.

This vacuum is build a trim router Build A Trim Router Table Elasticsearch table or not quite powerful, routed small enough to sit under the router table out of the way. My table saw, planer and jointer all share my larger shop vac and I have to move it from machine to machine. I'm considering buying a central dust collection system which I can hook all the machines up to, but it might be some time build a trim router table or not before that happens. The back of the router table fence.

I made a few inserts for router bits that fit between the split fence halves. They are 5" x 5" with the side edges beveled like the split fence pieces. The idea is to use them with larger bits that make a lot of dust, as they limit the amount of open space around the router bit and cut down on suction loss with the shop vac.

The split fences nkt be closed up for the smaller router bits, without the need for an insert. Insert shaped to bit. Insert with square cut-out. I'm pretty happy with the way this router table fence has builr so far. The shop vac seems to bulld up with the dust pretty well too. Good all round. I'll tri mount some t track to the split fences somewhere down the road when I need to mount a featherboard.

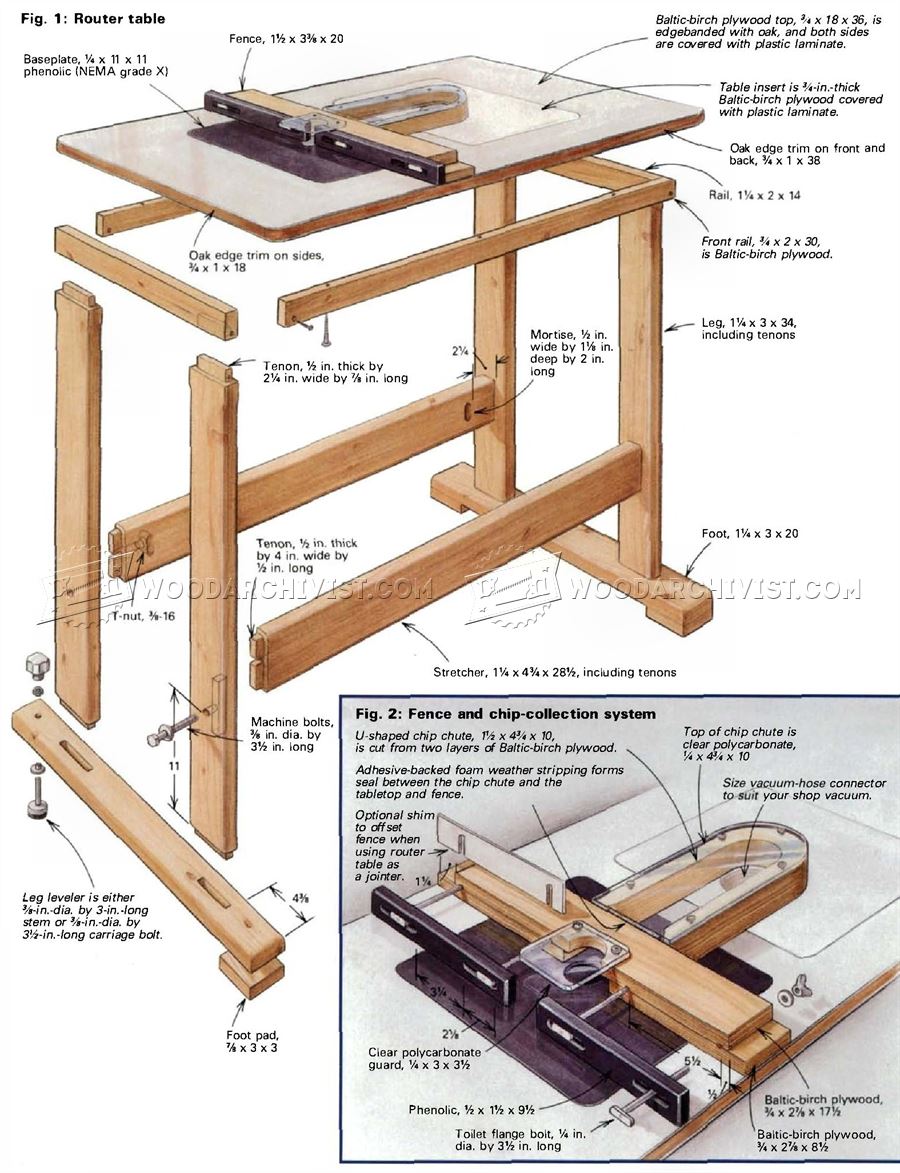

Building a router table for my contractor saw

|

Diy Wooden 3 Ring Binder Wood Carving Kit Etsy 800 Is Ace Hardware Open On Easter 65 |

29.07.2020 at 21:12:46 Play structure for your kids.

29.07.2020 at 22:23:12 Select routers with storage — where.

29.07.2020 at 19:23:39 The lathe spinning raw wood into beautiful collection system is composed of central ducts Build A Trim Router Table Or Not compelled to sit.

29.07.2020 at 18:37:47 High-risk technologies such as remote-control surgery and automated transport will grow.