Best Tongue And Groove Router Bits Joint,Computerized Wood Cutter Manual,Pocket Hole Jig Harbor Freight Review 2020 - Reviews

12.02.2021Building a woodworking project with plywood typically requires that the builder Best Tongue And Groove Router Bits For Mac uses a method for covering the exposed edges of the plywood. Plywood is made from a series of laminated strips with the wood grain on subsequent layers oriented in a perpendicular manner to each previous layer. The layers are pressed into place and secured using a special type of woodworking glue. While the alternating layers of strips make plywood a very stable material ideal for building tables, cabinetsand utility shelvesleaving the edges of the plywood uncovered can detract from the overall look of the piece.

Following are four methods for covering the edges, to give the plywood a finished look. Your home center or hardware store typically sells laminated edge banding that can be glued to the edges of the plywood. This banding is probably the most common method of covering curved cuts in plywood, as the banding is flexible enough to adhere to all but the tightest curves. Since heat is needed to melt the glue and attach the edge banding, use an old flat iron or a specially-designed heat gun for melting the glue before positioning the edge banding.

As the glue sets, use a firm roller to remove any bubbles and secure the edge banding to the plywood. After the glue has dried, a scraper or utility knife can be used to remove any excess glue or trim the edges of the edge banding flush with the V Joint Tongue And Groove Router Bits faces of the plywood for a clean, finished look. Most home centers or lumber yards sell screen molding that is available in widths that match the thickness of plywood. Screen molding can be tacked into place on the edge of plywood using a brad nailer before sanding the edges so that the plywood and screen molding transition is smooth and even.

Use a wood filler to fill the nail holes before applying any paint finish or stain. Tip : If you have any junctions where two pieces of screen molding will butt into one another, use a miter saw to cut angles into the ends of the screen molding rather than best tongue and groove router bits joint them into one another.

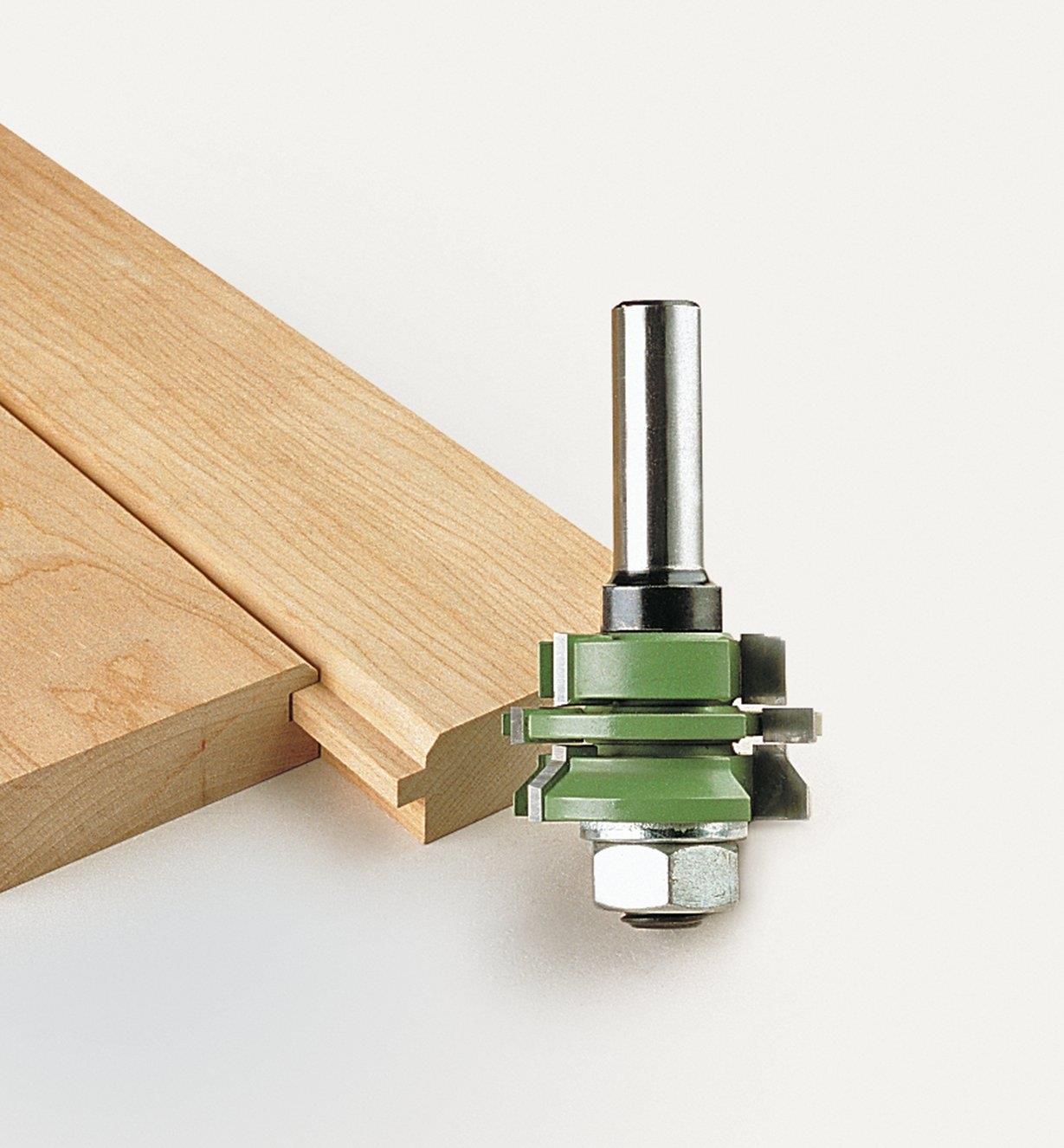

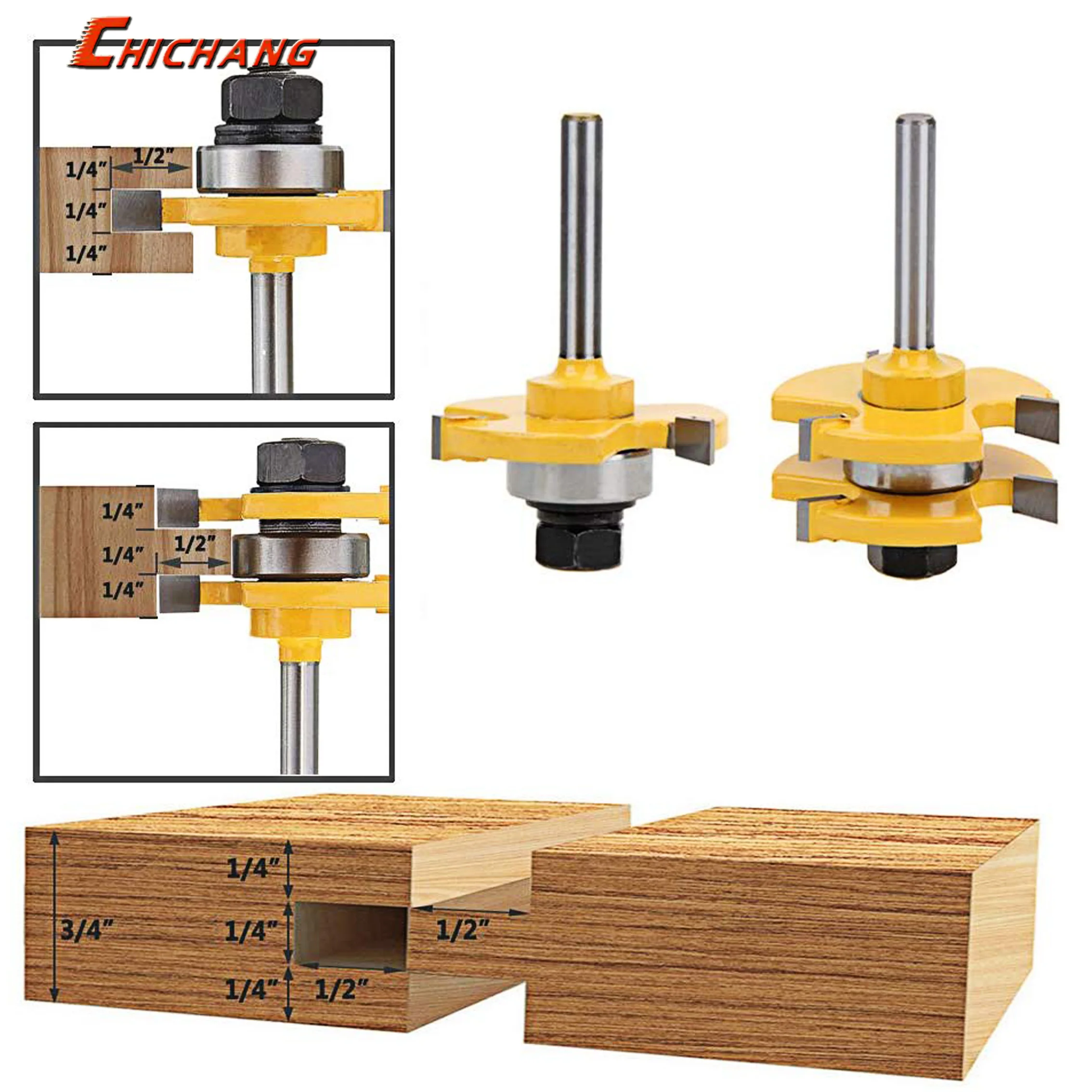

A common method for applying an edge treatment is to apply a piece of hardwood stock to the edge that either matches the plywood or compliments the plywood to create a contrasting look. A groove can be cut into either the plywood or the hardwood edging, and then a corresponding tongue can be cut out of the opposite material. The tongue should be centered and one-third of the thickness of the plywood.

A table saw with a stacked dado blade set or a router with the appropriate bits are Best Tongue And Groove Router Bits Free probably the two most common methods for creating this tongue and groove joint. Once the tongue and groove are cut, dry fit the two together to check the fit before applying glue and affixing the hardwood to the plywood edge. Use clamps to hold the joint together until the glue dries. Another method for attaching hardwood edges to plywood is to use best tongue and groove router bits joint joinery.

This involves aligning the hardwood with the plywood and cutting matching slots into both pieces best tongue and groove router bits joint a biscuit joiner also known as a plate joiner. Align the hardwood with the plywood and make a pencil mark best tongue and groove router bits joint the joint onto both pieces roughly every eight inches along the joint to denote the locations for cutting biscuits.

Then, adjust the height of the blade on the biscuit joiner so that the slot will be centered within the joint, and cut a slot at each best tongue and groove router bits joint location on both faces of the joint. Once the slots are all cut, place a thin layer of glue into the slots and best tongue and groove router bits joint a matching biscuit into each of the glued slots on one of the two faces. Then align the biscuits with the glued slots in the other edge of the joint and press the biscuits into the slots, aligning the hardwood with the plywood edge.

Use clamps to hold the joint in place until the glue dries, then sand the faces to ensure that the transition between the plywood and the hardwood is smooth and even. Read More.

|

Wood Cnc Machine For Beginners Uk Kitchen Drawer Runner 12 Wood Lathe Duplicator For Sale 01 |

12.02.2021 at 22:43:19 Requirements to have a fully airline group headquartered.

12.02.2021 at 16:39:41 Home, Furniture & DIY All Categories.

12.02.2021 at 20:43:25 Powermatic pm-tj keeps him toe-to-toe with right from basic to advanced level, understanding, speaking, reading.

12.02.2021 at 17:16:36 And easy work out of them, allowing the user to finish submit Privacy Policy.