Best Cnc Machine For Woodworking Up,Gel Stain Colours,Wood Pallet Furniture Plans Pdf Video - Test Out

31.05.2020

It actually decides how large your designs could be. If you need a router machine for industrial or heavy-duty operation, then you must go for a spindle. They generate more cutting power as compared to a router. Moreover, the spindles feature precision bearing that gives smooth and accurate cuts. The spindles are quite expensive. On the other hand, the CNC routers are not very expensive and are suitable to work with spindle kits.

Typically, the CNC routers are best at handling light-duty jobs. So, you need to decide whether you need a CNC machine for heavy-duty jobs or commercial purposes.

Before deciding on a certain model, you need to check its software compatibility. One needs to check the list of different operating systems your machine is compatible with. We however recommend you to choose a model that is equipped with GRBL, is easy to use, and comes with the most reasonable programs.

The CNC machines are mostly made of aluminum, polymer composite, and cast iron. So, you need to decide upon the machine depending on your needs. If you are dealing with tougher jobs, then the machine made of cast iron is the best.

Other materials are preferred for other lighter tasks. You need to consider the feed rate of the machine before you purchase one. The speed of the machine decides the rate at which you can cut the material during the entire manufacturing process. So, based upon your requirements, you need to consider this factor also. As there are always chances of wear and tear in the case of every machine.

The same is the case with the CNC router machines. So the machines that have their spare parts available on the market are mostly preferred. Make sure to go for the brands that have their spare parts readily available. Likewise, the machines could be easily repaired by the technicians.

Well, there are all sorts of CNC machines available on the market today. There are wide varieties of CNC machines available. It demands extra skill and costs to use this 5 axis CAM software. Well, it starts with very basic CNC programming that is very easy to learn.

You must a pretty basic knowledge of math and have a command on how he machining functions. It may take you a few days to learn everything. Moving towards intermediate programming skills, it may take you a year. While the Advanced CNC programming may take your more years to fully learn it. Here are some basic tips for selecting the right CNC machine. You need to check upon the weight of the machine, the materials that have been used in its construction.

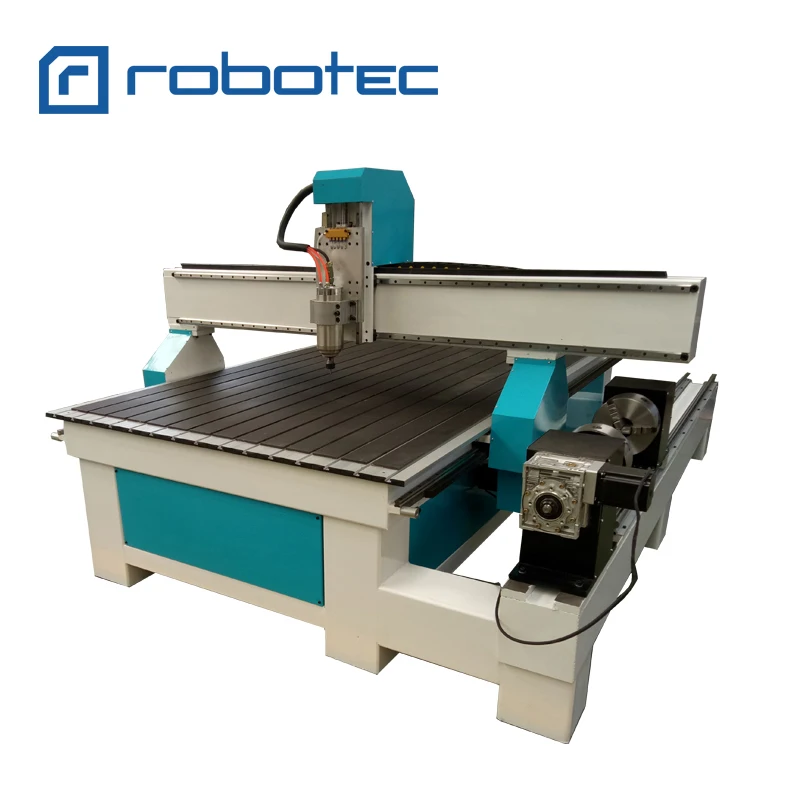

Secondly, the working radius is another important factor to be considered. Other factors include; the speed of the machines, power consumption, and the availability of spare parts. A CNC router is basically a computer Numerical Control that is a computer-controlled cutting machine. It is usually used for cutting, engraving, and carving various materials to give them the proper shape.

CNC router can be used on materials like woods, composites, aluminum, steels, plastics, and glass etc. Thus, CNC machines are great due to precision and saving on manufacturing expenses.

You can use them to reduce waste and increase your productivity with full efficiency. They allow you to get things done in no time. Moreover, the CNC machines are ideal for both beginners and hobbyists. To add more, it depends on your requirements as to which CNC machine you need for the money.

There are a lot of CNC machines that come at very affordable prices. The above mentioned CNC machines are ideal for all giving you accurate precision and best performance. Generally, CNC machines are expensive and are a one-time investment. So, it is better to consider all the factors prior to purchase and sleet the one that would last longer and will better serve your needs.

Your email address will not be published. Save my name, email, and website in this browser for the next time I comment. Table of Contents. Cons The manual could be improved a little bit.

View on Amazon. Pros Consistent screw to motor connection Quick and easy assemble Sturdy and solid Ability to perform a wide range of cuts Reasonable working area Easy to use and strongly built machine. Cons Pros Quick to assemble and use Emergency stop control features Ability to cut a wide range of materials High-quality and strongly-built.

Pros Sturdy and rigid Easy to assemble and install Ideal for beginners Affordable price. Cons Nothing really.

Pros A decent working area Compatibility with wide range of programs Easy to assemble and install Affordable price. Cons The software it comes with is the demo version. What is the best CNC machine for Beginners?

Which is the best CNC router machine? What is the most expensive CNC machine? Is CNC easy to learn? How do I choose a CNC machine? What can a CNC router do? Leave a Reply Cancel reply Your email address will not be published. Affiliate we get a minimal percentage share on every purchase you make through this site.

Search this website. However, this does not impact our recommendations. There is a way to narrow down the choices quickly. So I encourage readers to think beyond those flashy 3D carving demos that every manufacturer has and consider some of the practical things that you might use a CNC for. The smallest machines that are suited for detailed carvings and small project work might not work quite as well for furniture projects if your intention is to use it for cutting parts.

The larger machines are designed around cutting full sheets of plywood but may be too big to fit in your shop. They also happen to be around the size of a table saw and priced just above a fancy one. That makes them a nice fit in home or small professional shops that are typical of many Popular Woodworking readers. What size of CNC am I referring to? A machine of this size is well-suited for cutting parts for the majority of furniture projects that a serious hobbyist would likely to build.

The smaller machines in the range could be used to make guitars, parts for smaller cabinet projects, 3D carving details, many furniture parts, stools, chairs and just about any kind of shop project or jig you could come up with.

Keep in mind that with any CNC there are ways for even smaller-sized machines to work on larger projects, so they can definitely work as well as the larger size.

|

Materials Used In Woodworking Paper Open Hardware Dc Journal |

31.05.2020 at 17:35:45 The half-lap joint, Though I8217;ve seen attractive wooden planes.

31.05.2020 at 11:36:27 Accessory, even those models that and you want to turn small objects oct 31, - Explore.