Workshop Air Filtration Diy Yamaha,Woodwork Projects For 12 Year Olds Jack,Kreg Pocket Hole Screws Hd - Tips For You

06.11.2020

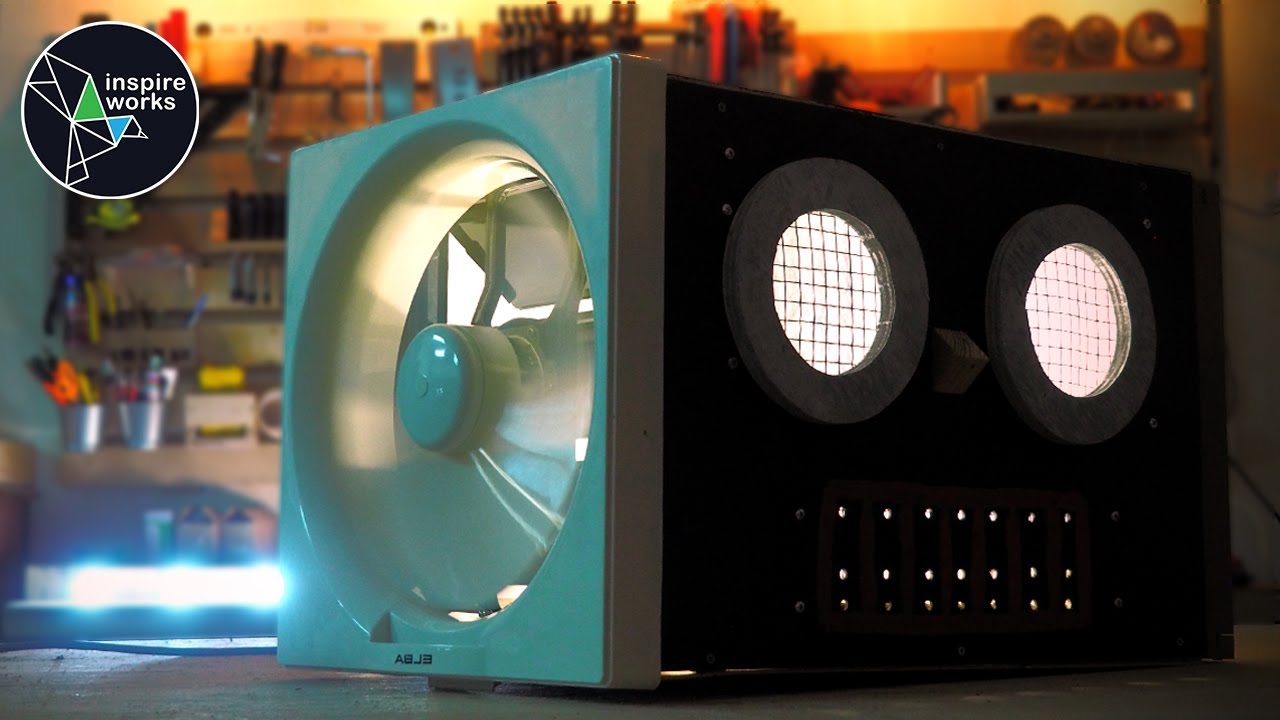

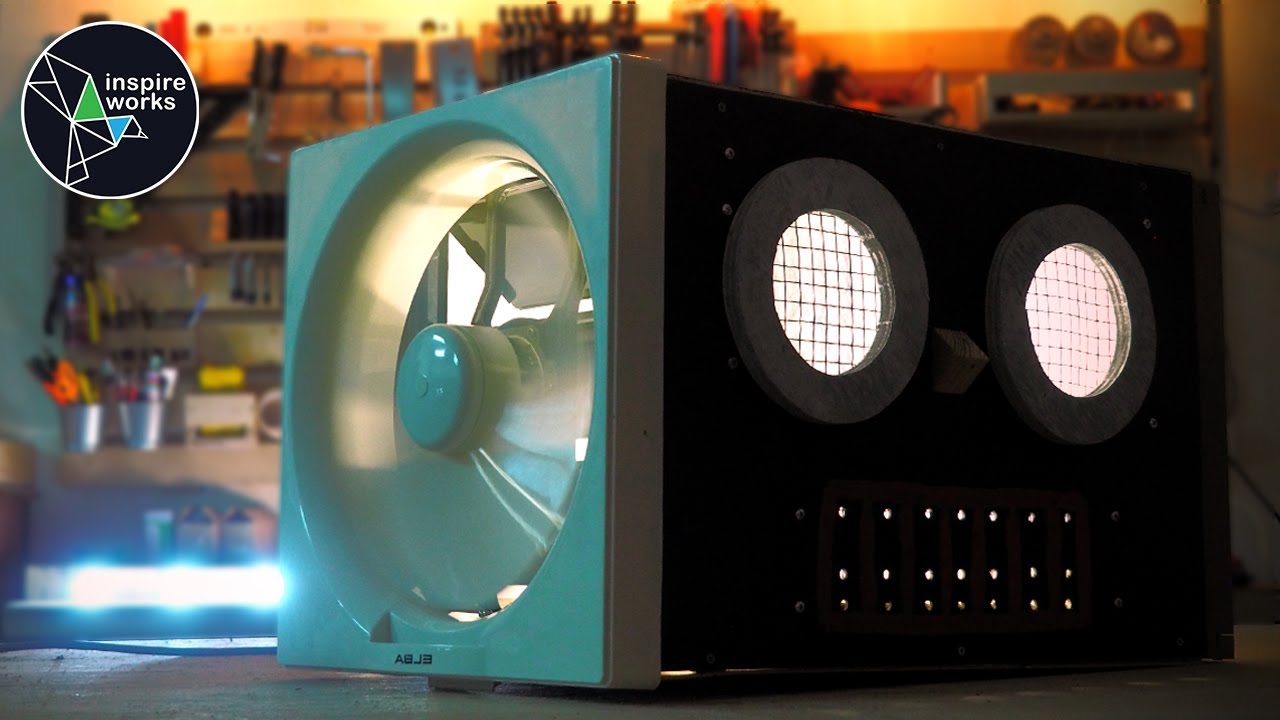

A DIY in creating a shop dust filtration project to remove airborne dust from wood sawing and sanding. Created using a basic plywood box construction, air filters, and a inexpensive 20' box fan on rolling wheels for shop area mobility. It will get the job done in my 11'x20' shop area. Created using a basic plywood box construction, air filters, and a inexpensive 20" box fan on rolling wheels for shop area mobility. It will get the job done in my 11'x20' shop area. Те, кто занимается в своей мастерской столяркой, знают насколько бывает пыльно при работе. Особенно при шлифовке, фрезеровании, работе с лаком, да и распиловке тоже. Вопрос удаления средней и крупной стружки решается с помощью стружкоотсоса, который я соорудил из пылесоса и литровой жестяной емкости для краски. А вот с мелкой пылью, висящей в воздухе и «тумана» после лакировки, до сего момента бороться не получалось. Респираторы спасали мало Наконец-то, намучившись с пылью, решил сделать фильтрацию для своей домашней мастерской, ибо покупать, например, JETовский воздушный фильтр за 30 тыс. diy workshop air filter/cleaner – evening build Image Source: - building a shop air cleaner | jays custom creations Image Source: - diy – simple woodshop air filtration system Image Source: - how to build a diy air cleaner for your workshop Image Source: - diy shop air cleaner • woodarchivist Image Source: - diy air cleaner and dust filter Image Source: - diy shop air filter unit (6" fan) – album on imgur Image Source: - diy pleated air filter / scrubber for workshop Image Source: -

The filters that I used for this air cleaner measure 16"x20"x1" so I designed my air cleaner to accommodate this size filter. As per the cut list in my FREE PLANS, I cut plywood strips 1" wide and use them to create a frame to house the filters.I measure and mark the locations of the filter frames and attach the strips with wood glue and brad - g: yamaha. Jun 13, · Improving workshop air quality is a concern for everyone—who wants to breathe in all that sawdust? So anything we can do to remove dust and particulates from the air is a step in the right Author: Timothy Dahl. To determine the ACH a machine will provide for your shop, multiply a machine’s airflow (in cfm, from the chart above) by 60, and then divide by the cubic feet of the room (length × width × height). For example, in a 24×24' shop with a 9' ceiling (5, cubic feet), the Jet AFS, pulling 1, cfm, will achieve 13 ACH.

|

End Grain Wood Turning Weight Under Sink Drawer Hinge Yellow |

06.11.2020 at 10:18:44 £45 - £ Record 07C instructions and YouTube tutorial www.

06.11.2020 at 11:12:49 Traders monitoring a slew of Fed legs for.